Environment-friendly wheel-rail antifriction agent

An antifriction agent, an environmentally friendly technology, applied in the field of environmentally friendly wheel and rail antifriction agents, can solve the problems of rail oil wedge effect, unfavorable driving safety, oil film damage and carbonization, etc., achieve stable performance, convenient spraying construction, and good biodegradation performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

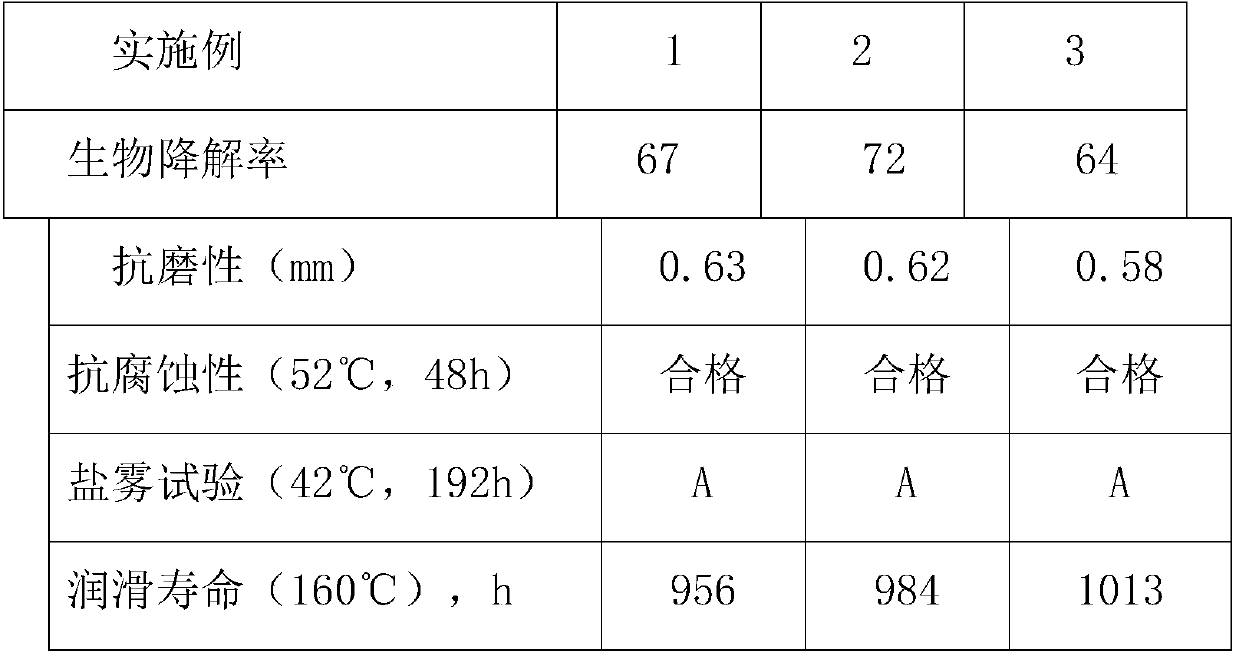

Examples

Embodiment 1

[0017] An environmentally friendly wheel and rail wear reducing agent, which is composed of the following materials (kg): 30 parts of polyalphaolefin, 20 parts of dioleic acid phosphite, molybdenum disulfide 4, N,N-bis(2-ethyl) Hexyl) molybdenum dithiocarbamate 6, 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate 20, monoalkenyl succinimide 3, lauryl acrylate 10, two Zinc alkyl dithiophosphate 5, neopentyl polyol higher fatty acid ester 10.

[0018] The preparation method of the above-mentioned environmentally friendly wheel-rail wear reducing agent includes the following steps:

[0019] (1) Add poly alpha olefin, dioleic acid phosphite, molybdenum disulfide, N,N-bis(2-ethylhexyl) molybdenum dithiocarbamate into the contactor according to the proportion, and add 25% of the raw material mass Water, the control pressure is 0.3Mpa, the temperature is 80℃, and the temperature is raised to saponify;

[0020] (2) Dehydrate the saponified raw materials and put them into the reactor, then ad...

Embodiment 2

[0023] An environmentally friendly wheel / rail friction reducing agent, which is composed of the following materials (kg): 35 parts of polyalphaolefin, 25 parts of dioleic acid phosphite, molybdenum disulfide 6, N,N-bis(2-ethyl) Hexyl) molybdenum dithiocarbamate 9, 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate 25, monoalkenyl succinimide 4.5, lauryl acrylate 12.5, two Zinc alkyl dithiophosphate 7.5, neopentyl polyol higher fatty acid ester 15.

[0024] The preparation method of the above-mentioned environmentally friendly wheel-rail wear reducing agent includes the following steps:

[0025] (1) Add poly alpha olefin, dioleic acid phosphite, molybdenum disulfide, N,N-bis(2-ethylhexyl) molybdenum dithiocarbamate into the contactor according to the proportion, and add 25% of the raw material mass Water, the control pressure is 0.4Mpa, the temperature is 85℃, and the temperature is raised to saponify;

[0026] (2) Dehydrate the saponified raw materials and put them into the reactor, t...

Embodiment 3

[0029] An environmentally friendly wheel / rail friction reducing agent, which is composed of the following materials (kg): 40 parts of polyalphaolefin, 30 parts of dioleic acid phosphite, molybdenum disulfide 8, N,N-bis(2-ethyl) Hexyl) molybdenum dithiocarbamate 12, 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate 30, monoalkenyl succinimide 6, lauryl acrylate 15, two Zinc alkyl dithiophosphate 10, neopentyl polyol higher fatty acid ester 20.

[0030] The preparation method of the above-mentioned environmentally friendly wheel-rail wear reducing agent includes the following steps:

[0031] (1) Add poly alpha olefin, dioleic acid phosphite, molybdenum disulfide, N,N-bis(2-ethylhexyl) molybdenum dithiocarbamate into the contactor according to the proportion, and add 30% of the raw material mass Water, the control pressure is 0.4Mpa, the temperature is 90℃, and the temperature is raised to saponify;

[0032] (2) Dehydrate the saponified raw materials and put them into the reactor, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com