High-temperature-resistant bacillus hisashii and high-temperature compost fermentation method

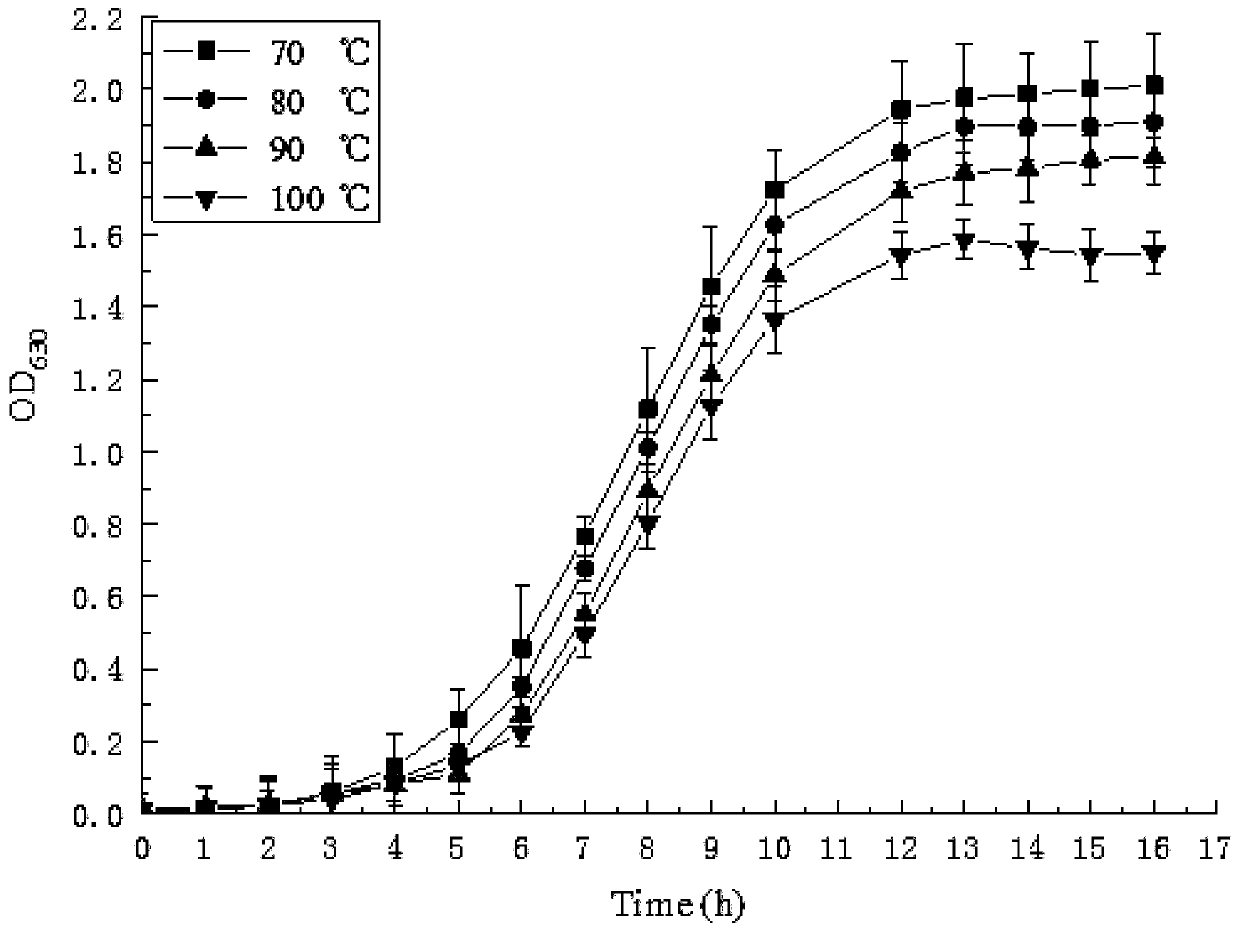

A technology of bacillus and fermentation method, which is applied in the field of microbial technology and environmental engineering, and can solve the problems of difficulty in reaching higher fermentation temperature, lack of fermentation, and death of functional microorganisms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1: Food waste composting treatment

[0061] Take 5 tons of kitchen waste, add it to the fermentation device with cutting and stirring, and continuously cut and stir it into pieces of about 5cm, put in 3% quicklime, control the moisture content of the material at 80%, put in 2.5g of alkaline amylase after mixing , 1g of alkaline protease and 2.5g of esterase continued to mix and stir, and turned on the electric heating to raise the temperature to 35°C and maintain it for 1h. Put in 2 tons of HN-1 inoculant sawdust, (during production, the volume ratio of liquid inoculant to dry sawdust is 1:1.1) and stir thoroughly, increase the electric heating power to raise the temperature to 45°C, and start high-temperature composting. After 4 hours of start-up, the temperature of the compost heap rose to 65°C, and gradually increased within 24 hours of start-up, and finally reached 85-100°C, and the humidity gradually decreased from the initial 80% to about 50% at last. ...

Embodiment 2

[0062] Example 2: Farming solid waste composting

[0063] Take 10 tons of pig farm feces, put in 4% quicklime, stir evenly, control the moisture content of the material at 82%, put in 5.5g of alkaline amylase, 5.0g of alkaline protease, and 10g of esterase, continue to mix and stir, and turn on the electric heating to raise the temperature to 40°C and maintain for 1h. Put in 4 tons of HN-1 inoculant sawdust, (during production, the volume ratio of liquid inoculum to dry sawdust is 1:0.8) and stir thoroughly, increase the electric heating power to raise the temperature to 45°C, and start high-temperature composting. 4 hours after start-up, the temperature of the compost heap rose to 65°C, and gradually increased within 24 hours of start-up, and finally reached 85-100°C, and the humidity gradually decreased from the initial 80% to about 55% at last. Then the temperature dropped slowly, and the temperature dropped to 65°C within 48 hours of starting. At this time, 20% of the vol...

Embodiment 3

[0064] Example 3: Fertilizer composting of agricultural by-products

[0065] Take 5 tons of straw, add it to the fermentation device with cutting and stirring, and continuously cut and stir it into pieces of about 6cm. Put in 3% quicklime, stir evenly, control the moisture content of the material at 85%, put in 3.0g alkaline amylase, 2.5g alkali Protease and 4.0 g of esterase were mixed and stirred, and the electric heating was turned on to raise the temperature to 40° C. and maintained for 2 hours. Put in 2.5 tons of HN-1 inoculum sawdust, (during production, the volume ratio of liquid inoculum to dry sawdust is 1:1.2) and stir thoroughly, increase the electric heating power to raise the temperature to 45°C, and start high-temperature composting. Six hours after start-up, the temperature of the compost heap rose to 65°C, and gradually increased within 24 hours of start-up, and finally reached 85-100°C, and the humidity gradually decreased from the initial 85% to about 55% at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com