Preparation method and application of ZnO-SnO2-Zn2SnO4 porous nanofiber gas sensitive material

A zno-sno2-zn2sno4 and nanofiber technology is applied in the field of gas sensors, which can solve the problems of unfavorable large-scale application and high working temperature, and achieve the effects of uniform and controllable morphology, reduction of recombination rate and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add 0.768g zinc acetate dihydrate and 0.8392g tin acetate to 5.5mL, 2mol / L N,N dimethylformamide; then add 0.700g polyvinylpyrrolidone to the above mixed solution to make the solution have a certain viscosity degree, the above solution was stirred at room temperature for 11.5 h to obtain a precursor solution for electrospinning. The process parameters in the spinning process are: high voltage 17kV, negative high voltage -1kV, precursor liquid flow rate 1.0mL / h, distance between spinning head and receiver 13cm. The precursor nanofibers obtained by spinning were calcined in air, the calcination heating rate was set to 8°C / min, the calcination temperature was raised to 680°C and kept for 1 hour, and finally ZnO-SnO 2 -Zn 2 SnO 4 Porous nanofiber gas-sensing material with a fiber diameter of 180nm.

Embodiment 2

[0035] Add 0.878g zinc acetate dihydrate and 0.7438g tin acetate to 4.8mL, 2mol / L N,N dimethylformamide; then add 0.7g polyvinylpyrrolidone to the above mixed solution to make the solution have a certain viscosity degree, the above solution was stirred at room temperature for 12 h to obtain a precursor solution for electrospinning. The process parameters in the spinning process are: high voltage 15.3kV, negative high voltage 2kV, precursor liquid flow rate 1.2mL / h, and the distance between the spinning head and the receiver is 15cm. The precursor nanofibers obtained by spinning were calcined in the air, the calcination heating rate was set to 10°C / min, the calcination temperature was raised to 650°C and kept for 3 hours, and finally ZnO-SnO 2 -Zn 2 SnO 4 Porous nanofiber gas sensing materials.

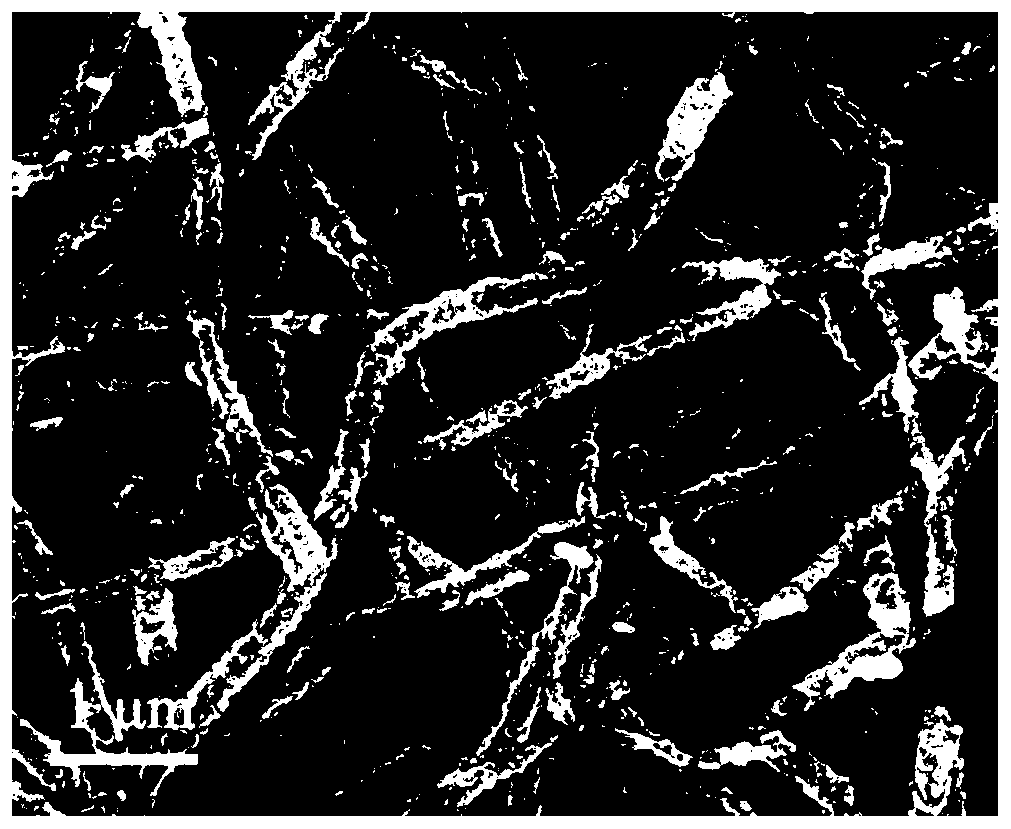

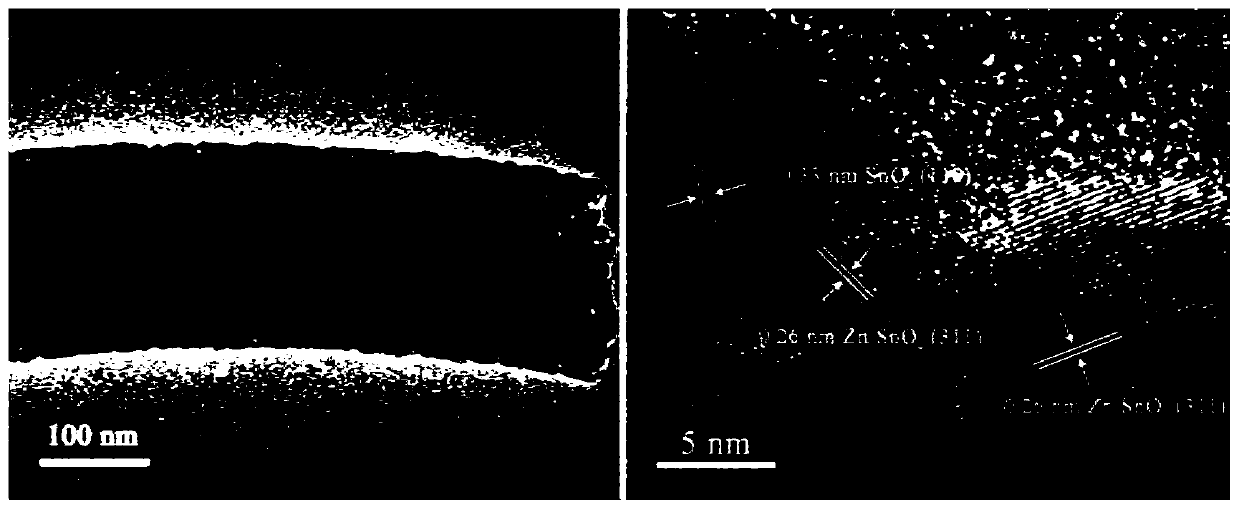

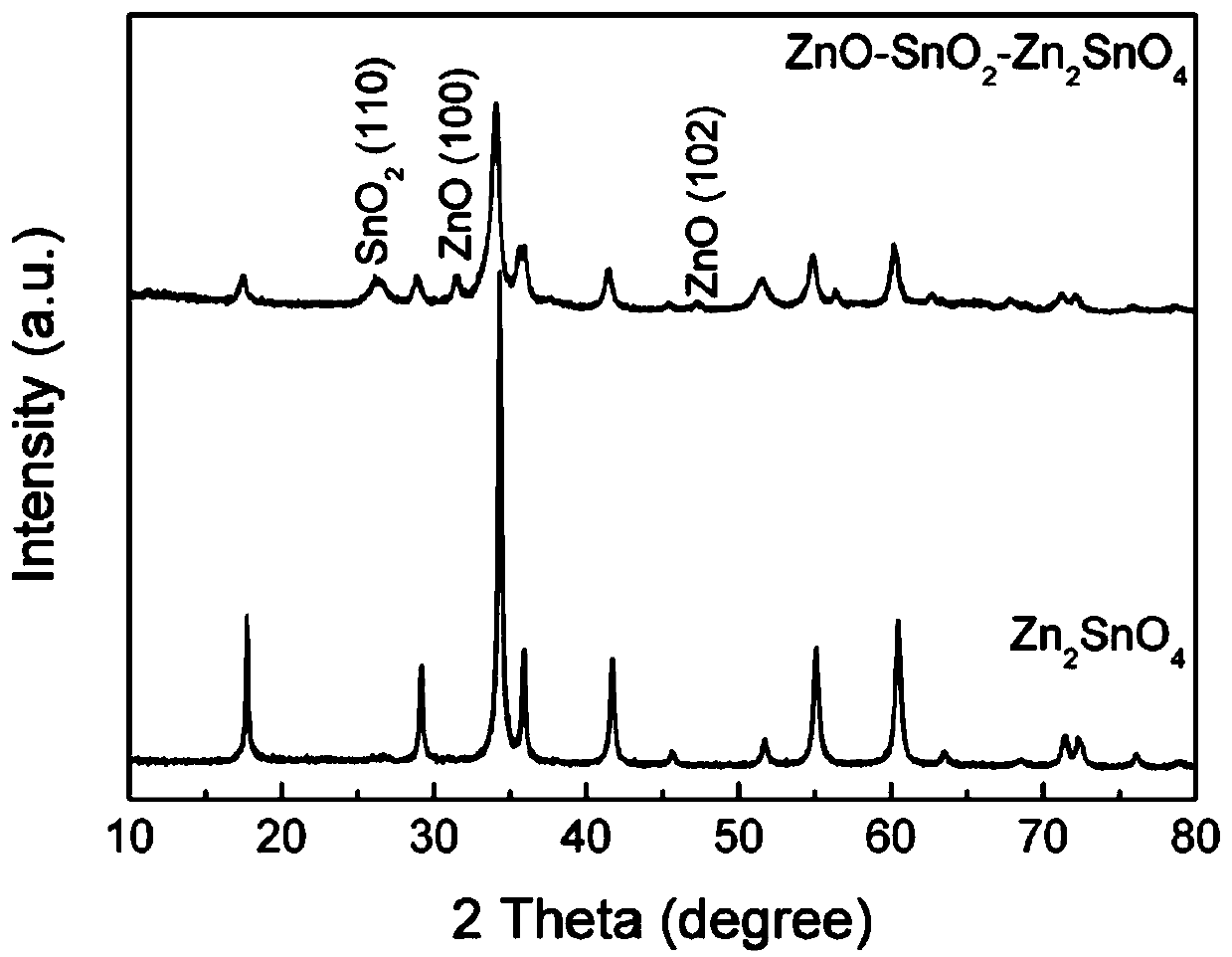

[0036] In the present embodiment, for the scanning electron microscope (SEM) photo, TEM picture and HRTEM scanning test of the prepared crystal product, see respectively figure 1 ,...

Embodiment 3

[0042] Add 0.9801g of zinc acetate dihydrate and 0.7951g of tin acetate to 6.7mL, 2mol / L N,N dimethylformamide; then add 0.7g of polyvinylpyrrolidone to the above mixed solution to make the solution have a certain viscosity degree, the above solution was stirred at room temperature for 12.5 h to obtain a precursor solution for electrospinning. The technological parameters in the spinning process are: high voltage 16kV, negative high voltage 1kV, precursor liquid flow rate 1.5mL / h, and the distance between the spinning head and the receiver is 16cm. The precursor nanofibers obtained by spinning were calcined in air, the calcination heating rate was set to 13°C / min, the calcination temperature was raised to 670°C and kept for 2 hours, and finally ZnO-SnO 2 -Zn 2 SnO 4 Porous nanofiber gas sensing material with a fiber diameter of 220nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com