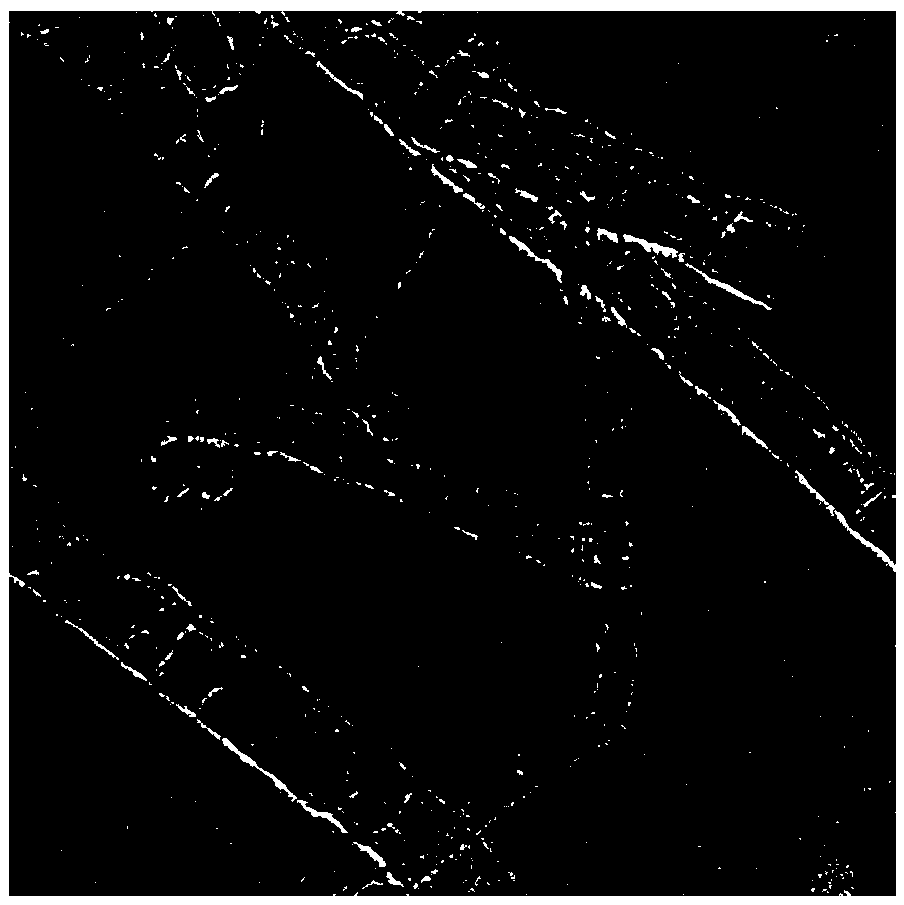

Preparation method for bamboo-like graphene tube/sulfur composite material

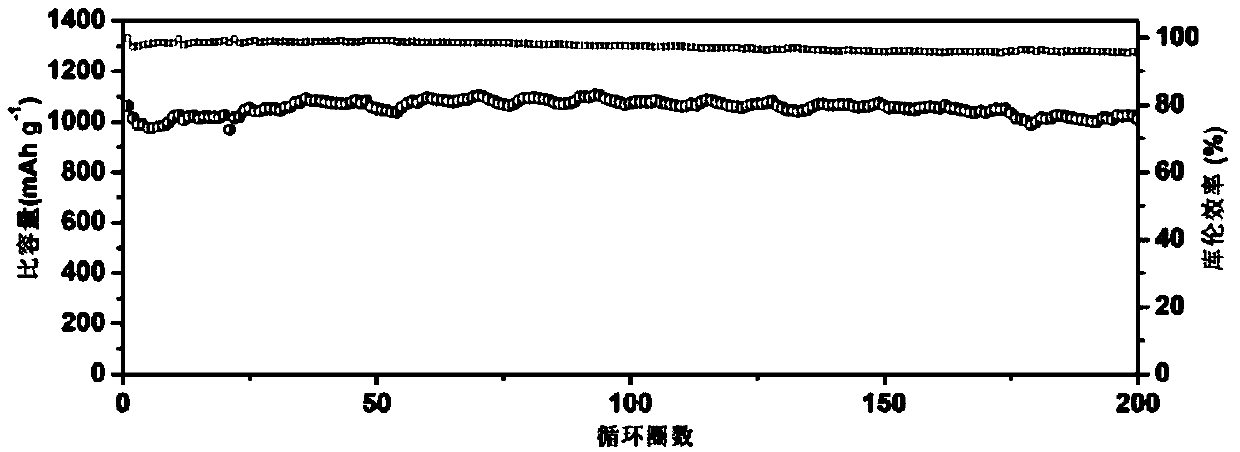

A technology of graphene tubes and composite materials, applied in the direction of graphene, nano-carbon, structural parts, etc., can solve the problems of high cost, unfavorable large-scale application, complicated process, etc., and achieve simple operation, low raw material cost, and good rate performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Preparation of bamboo-shaped graphene tube: weigh 17.95g dicyandiamide, 2.8g cobalt acetate tetrahydrate, 2.8g nickel acetate tetrahydrate, 1.95g ferric nitrate, add 1L deionized water, and stir for 10min at 60°C . After it was uniformly dispersed, the reaction was continued at 60°C for 24 hours. After the reaction, the temperature was raised to 70°C, and the water was evaporated to dryness to obtain a solid product. The product was then put into a vacuum tube furnace, and nitrogen was used as a protective gas. The temperature was raised to 1000°C at a heating rate of 10°C / min, and a high-temperature reduction reaction was carried out. 1h. Subsequently, 50 mL of dilute sulfuric acid solution with a concentration of 0.5 mol / L was added, stirred for 30 minutes, and then centrifuged, and the solid phase was washed and dried to obtain a bamboo-shaped graphene tube.

[0026] 2) Preparation of bamboo-shaped graphene tube / sulfur composite material: the bamboo-shaped graph...

Embodiment 2

[0029] 1) Preparation of bamboo-shaped graphene tube: weigh 35.9g of dicyandiamide, 5.6g of cobalt acetate tetrahydrate, 5.6g of nickel acetate tetrahydrate, 3.9g of ferric nitrate, add 2L of deionized water, and stir for 10min at 60°C . After it was uniformly dispersed, the reaction was continued at 60°C for 24 hours. After the reaction, the temperature was raised to 70°C, and the water was evaporated to dryness to obtain a solid product. The product was then put into a vacuum tube furnace, and nitrogen was used as a protective gas. The temperature was raised to 1000°C at a heating rate of 10°C / min, and a high-temperature reduction reaction was carried out. 1h. Subsequently, 50 mL of dilute sulfuric acid solution with a concentration of 1 mol / L was added, stirred for 30 minutes, and then centrifuged, and the solid phase was washed and dried to obtain a bamboo-shaped graphene tube.

[0030] 2) Preparation of bamboo-shaped graphene tube / sulfur composite material: the bamboo-s...

Embodiment 3

[0033]1) Preparation of bamboo-shaped graphene tube: Weigh 8.975g dicyandiamide, 1.4g cobalt acetate tetrahydrate, 1.4g nickel acetate tetrahydrate, 0.975g ferric nitrate, then add 0.5L deionized water, at 60°C Stir for 10 min. After it was uniformly dispersed, the reaction was continued at 60° C. for 24 hours. After the reaction, the temperature was raised to 70°C, and the water was evaporated to dryness to obtain a solid product, and then the product was placed in a vacuum tube furnace with nitrogen as a protective gas, and the temperature was raised to 1000°C at a heating rate of 10°C / min for high-temperature reduction reaction 1h. Then add 50 mL of dilute sulfuric acid solution with a concentration of 0.5 mol / L, stir for pickling for 30 min, then centrifuge, take the solid phase for washing, and dry to obtain bamboo-shaped graphene tubes.

[0034] 2) Preparation of bamboo-shaped graphene tube / sulfur composite material: mix the bamboo-shaped graphene tube and sulfur at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com