Ce-doped sodium nickel phosphate photocatalytic material and preparation method thereof

A photocatalytic material, sodium nickel phosphate technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as high cost, poor photocatalytic effect, and high toxicity, and achieve cost Inexpensive, easy to mass-produce, and control simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

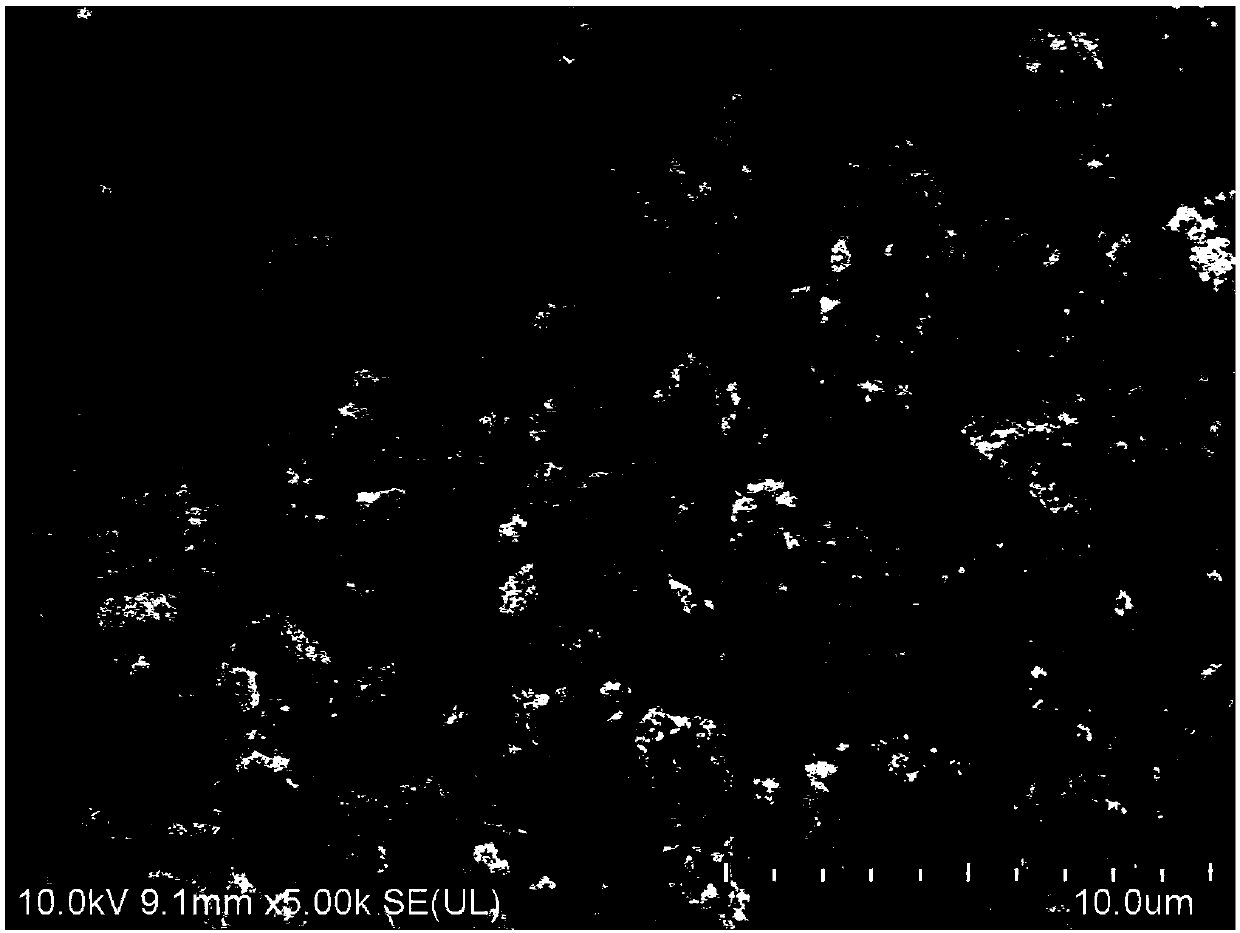

[0042] According to the molar ratio of 1.2:1, take by weighing sodium-containing basic nickel carbonate and sulfuric acid solution respectively, and add the sodium-containing basic nickel carbonate in the phosphoric acid solution for dissolution reaction to obtain sodium-containing nickel phosphate solution; Weigh Ce(NO 3 ) 3 , and Ce(NO 3 ) 3 Add the sodium-containing nickel phosphate solution obtained above and stir the reaction for 4 hours, then concentrate and crystallize to obtain a crystallization mixture of Ce-doped sodium nickel phosphate; Carry out calcination for 6h, and then cool down to obtain Ce-doped sodium nickel phosphate photocatalytic material.

[0043] Wherein, the concrete preparation method of sodium-containing basic nickel carbonate is as follows:

[0044] Add the sodium carbonate solution with a concentration of 180g / L and the nickel sulfate solution with a concentration of 60g / L into the reactor at the same time. During the feeding process, adjust the...

Embodiment 2

[0047] Take sodium-containing basic nickel carbonate and sulfuric acid solution respectively according to the molar ratio of 1:1, and add sodium-containing basic nickel carbonate into the phosphoric acid solution for dissolution reaction to obtain sodium-containing nickel phosphate solution; Weigh Ce(NO 3 ) 3 , and Ce(NO 3 ) 3 Add the sodium-containing nickel phosphate solution obtained above and stir for 3 hours, then concentrate and crystallize to obtain a crystallization mixture of Ce-doped sodium nickel phosphate; Carry out calcination for 2 hours, and then cool to obtain Ce-doped sodium nickel phosphate photocatalytic material.

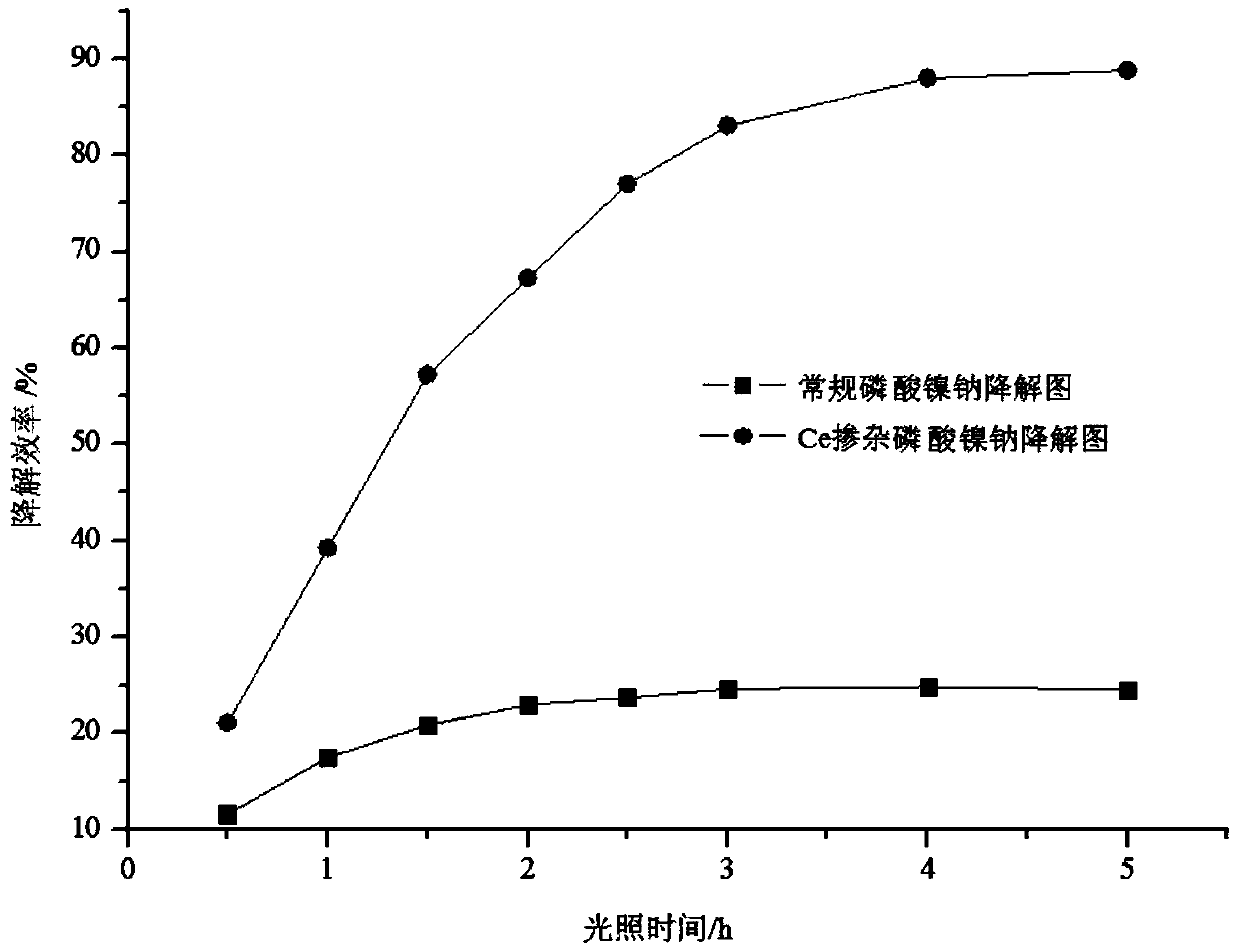

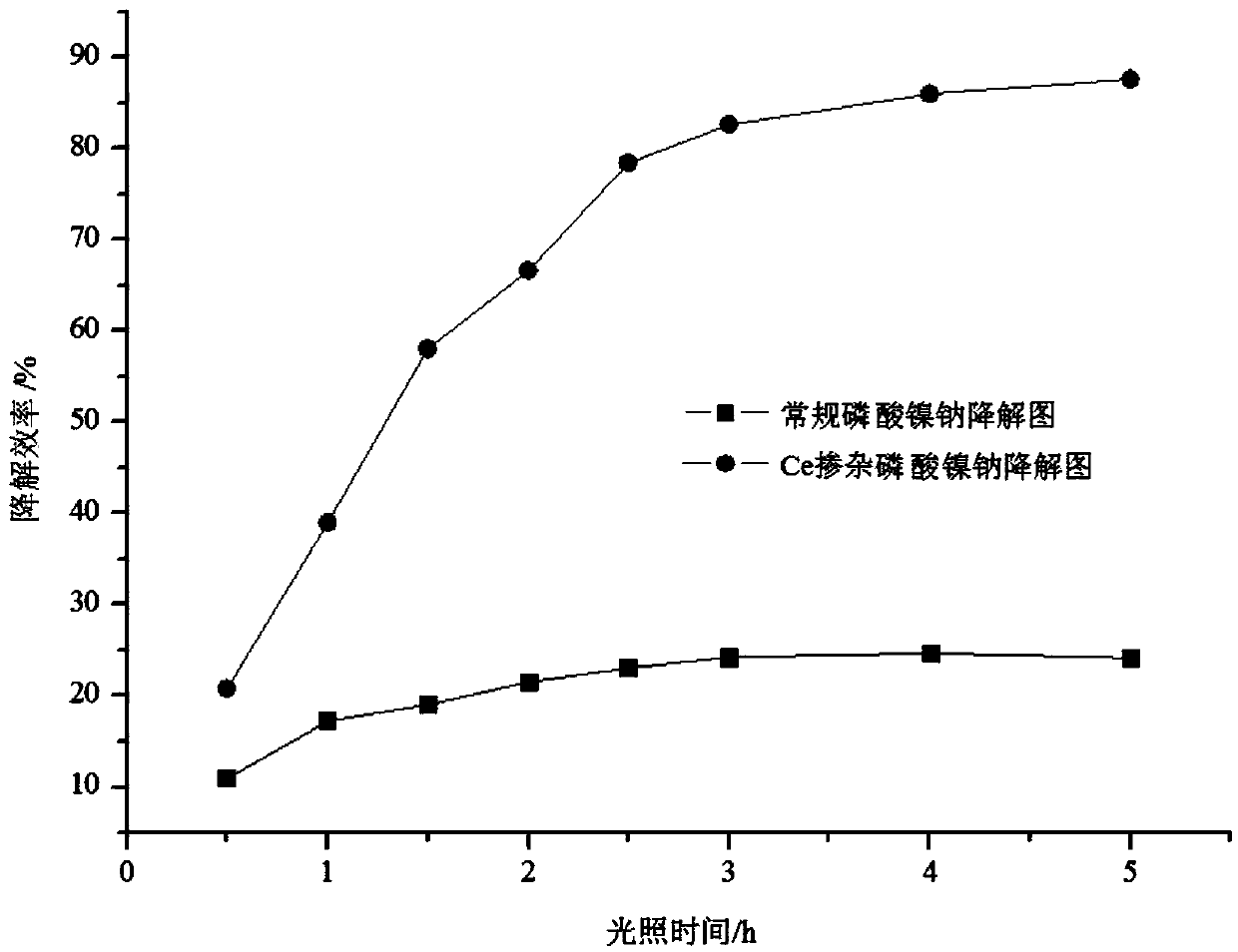

[0048] It can be seen from experiments that the Ce-doped sodium nickel phosphate photocatalytic material prepared in Example 2 has a main structure and morphology similar to that of Example 1, thus also confirming that the Ce-doped sodium nickel phosphate has strong photocatalytic properties. properties and can be used as inorganic catalytic ...

Embodiment 3

[0050] According to the molar ratio of 1.3:1, take by weighing sodium-containing basic nickel carbonate and sulfuric acid solution respectively, and add the sodium-containing basic nickel carbonate in the phosphoric acid solution for dissolution reaction to obtain sodium-containing nickel phosphate solution; Weigh Ce(NO 3 ) 3 , and Ce(NO 3 ) 3 Add the sodium-containing nickel phosphate solution obtained above and stir the reaction for 5 hours, then concentrate and crystallize to obtain a crystallization mixture of Ce-doped sodium nickel phosphate; Calcining for 10 hours and then cooling to obtain a Ce-doped sodium nickel phosphate photocatalytic material.

[0051] It can be seen from experiments that the Ce-doped sodium nickel phosphate photocatalytic material prepared in Example 3 has a main structure and morphology similar to that of Example 1, thus also confirming that the Ce-doped sodium nickel phosphate has strong photocatalytic properties. It can be used as an inorga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com