Preparation method of high-water solubility polyacrylamide

A technology for polyacrylamide and acrylamide, which is applied in the field of water-soluble polymer material synthesis, can solve the problems of complicated operation steps, complicated preparation methods, improper handling and the like, and achieves the effects of simplified technological process, simple preparation method and complete reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

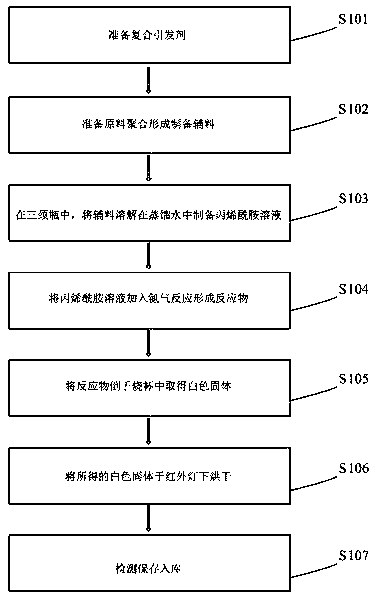

[0043] The preparation method of highly water-soluble polyacrylamide specifically comprises the following steps:

[0044] S101: preparing the same water-soluble raw material to form a composite initiator;

[0045] S102: Prepare acrylamide and benzoyl peroxide again for polymerization to form auxiliary materials;

[0046] S103: In the three-necked bottle, dissolve the auxiliary materials in distilled water, and continuously inject nitrogen gas into the three-necked bottle, and control it within a reasonable range of time, and then add benzoyl peroxide in a reasonable range in real time until propylene is formed Amide solution;

[0047] S104: Connect one of the ports of the three-necked bottle to a reflux condenser, install a stirrer on the middle port of the three-necked bottle, and carry out stirring and reflux. At the same time, the water bath is heated to a reasonable temperature range to start the reaction, and the reaction lasts for three Nitrogen gas is passed into the ...

specific Embodiment 1

[0061] 1. Dissolve 15 grams of ammonium persulfate in 200 ml of water;

[0062] 2. Dissolve 20 grams of acrylamide in 60 milliliters of water, add 0.3 grams of nano-silica and 15 milliliters of ammonium persulfate solution, and stir for 20 minutes with a stirring bar;

[0063] 3. Pour the mixture into a plastic bottle, place it in a vacuum drying oven at 80 degrees Celsius for 6 to 8 minutes, open the vacuum valve, pump the pressure in the oven to 0.21 MPa, and react for 5 hours;

[0064] 4. Put the product in an oven at 85 degrees Celsius for 4 to 5 hours, take it out, cut it into small pieces, put it in an oven at 85 degrees Celsius until it is dry, take it out and crush it.

specific Embodiment 2

[0066] 1. Dissolve 15 grams of ammonium persulfate in 200 ml of water;

[0067] 2. Dissolve 25 grams of acrylamide in 65 milliliters of water, add 0.4 grams of nano-silica and 20 milliliters of ammonium persulfate solution, and stir for 30 minutes with a stirring bar;

[0068] 3. Pour the mixture into a plastic bottle, place it in a vacuum drying oven at 80 degrees Celsius for 6 to 8 minutes, open the vacuum valve, pump the pressure in the oven to 0.21 MPa, and react for 5 hours;

[0069] 4. Put the product in an oven at 85 degrees Celsius for 4 to 5 hours, take it out, cut it into small pieces, put it in an oven at 85 degrees Celsius until it is dry, take it out and crush it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com