Transparent coating for photovoltaic back plate and the photovoltaic back plate

A technology of transparent coatings and photovoltaic backsheets, applied in photovoltaic power generation, polyurea/polyurethane coatings, coatings, etc., can solve the problem of low adhesion between the backsheet and the encapsulation film, low surface energy of the inner layer material, and corona process. Cumbersome and other problems, to avoid surface energy decay, save process steps, save process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

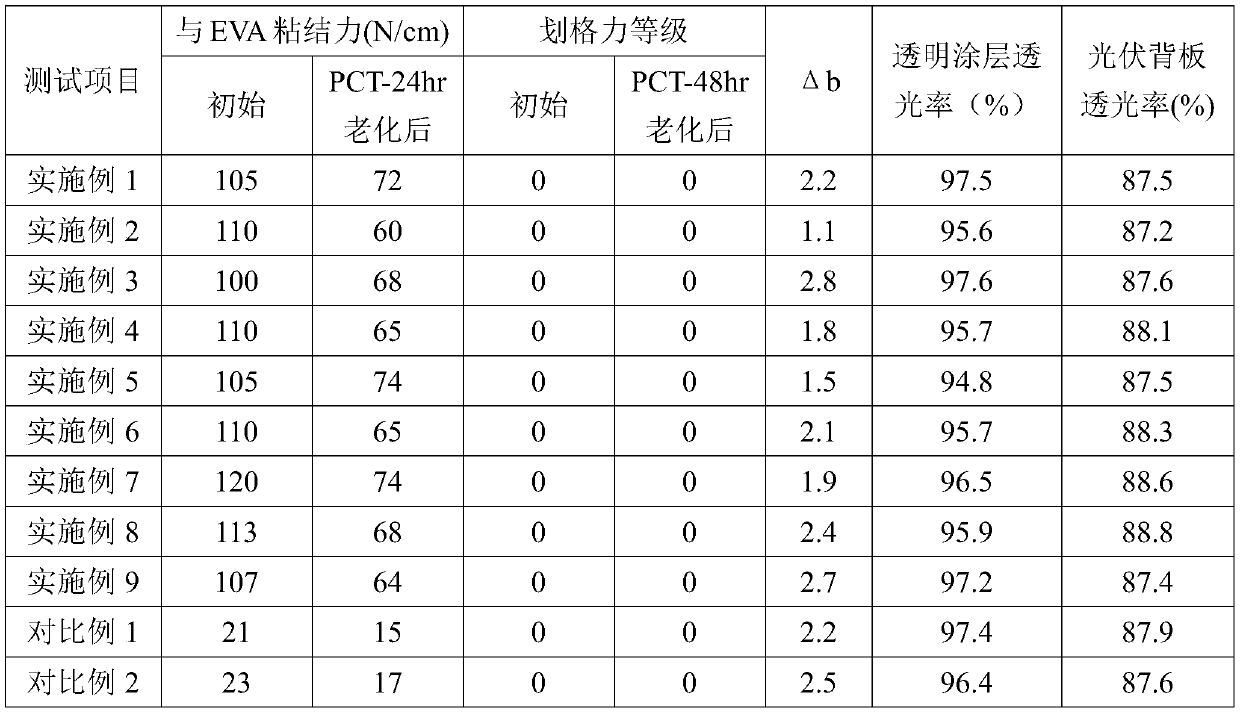

Examples

Embodiment 1

[0059] This embodiment provides a transparent coating for a photovoltaic backplane and a photovoltaic backplane;

[0060] The transparent paint includes a solvent and solid components dispersed in the solvent, and the solid content of the transparent paint is 60%;

[0061] Among them, the solvent is composed of butyl acetate and toluene in a mass ratio of 3:1, and the solid components include the following components in weight percentage: 65.5% of hydroxyl-containing fluorocarbon resin (ZHM-3 of Sanaifu), aluminum oxide (particle size 0.5-2μm) 18.7%, oligomer alkane coupling agent (Evonik Degussa’s Dynasylan 6498) 2.8%, isocyanate curing agent (Yantai Wanhua HT-100) 8.1%, UV absorber (BASF Tinuvin400) 2.8% , UV stabilizer (BASF Tinuvin123) 0.7%, dispersant (BYK163 of BYK) 0.7% and defoamer (BYK610 of BYK) 0.7%.

[0062] The photovoltaic backplane comprises a transparent substrate layer and a transparent coating disposed on one side of the transparent substrate layer, and the ...

Embodiment 2

[0065] This embodiment provides a transparent coating for a photovoltaic backplane and a photovoltaic backplane. The only difference from Embodiment 1 is that the thickness of the transparent coating is 10 μm.

Embodiment 3

[0067] This embodiment provides a transparent coating for a photovoltaic backplane and a photovoltaic backplane. The only difference from Embodiment 1 is that the ultraviolet absorber is UV571.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com