Cobalt selenide and carbon composite material for negative electrode of high-performance potassium ion battery, preparation method of cobalt selenide and carbon composite material and matched electrolyte

A carbon composite material and battery negative electrode technology, applied in the field of electrochemistry, can solve the problems of poor shape maintenance, cumbersome steps, and poor cycle stability, so as to improve electrochemical performance, enhance charge transfer, and reduce reaction. The effect of impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

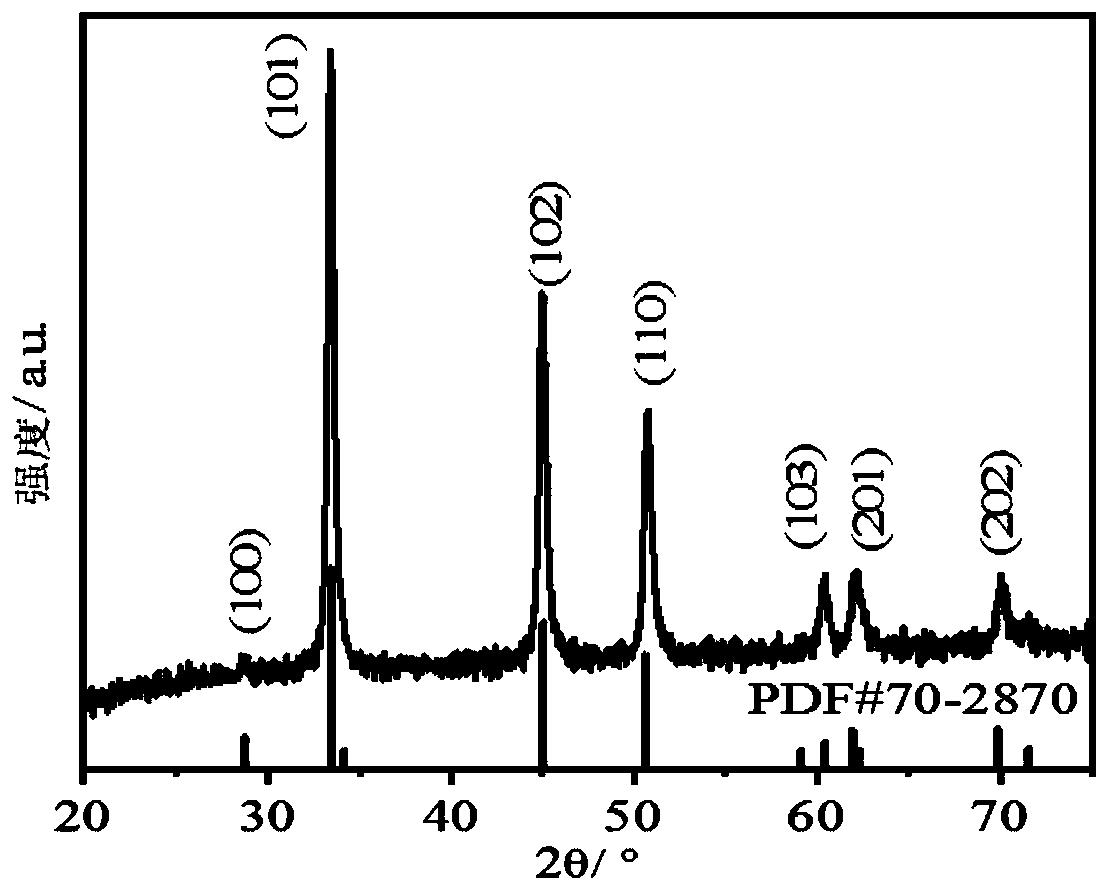

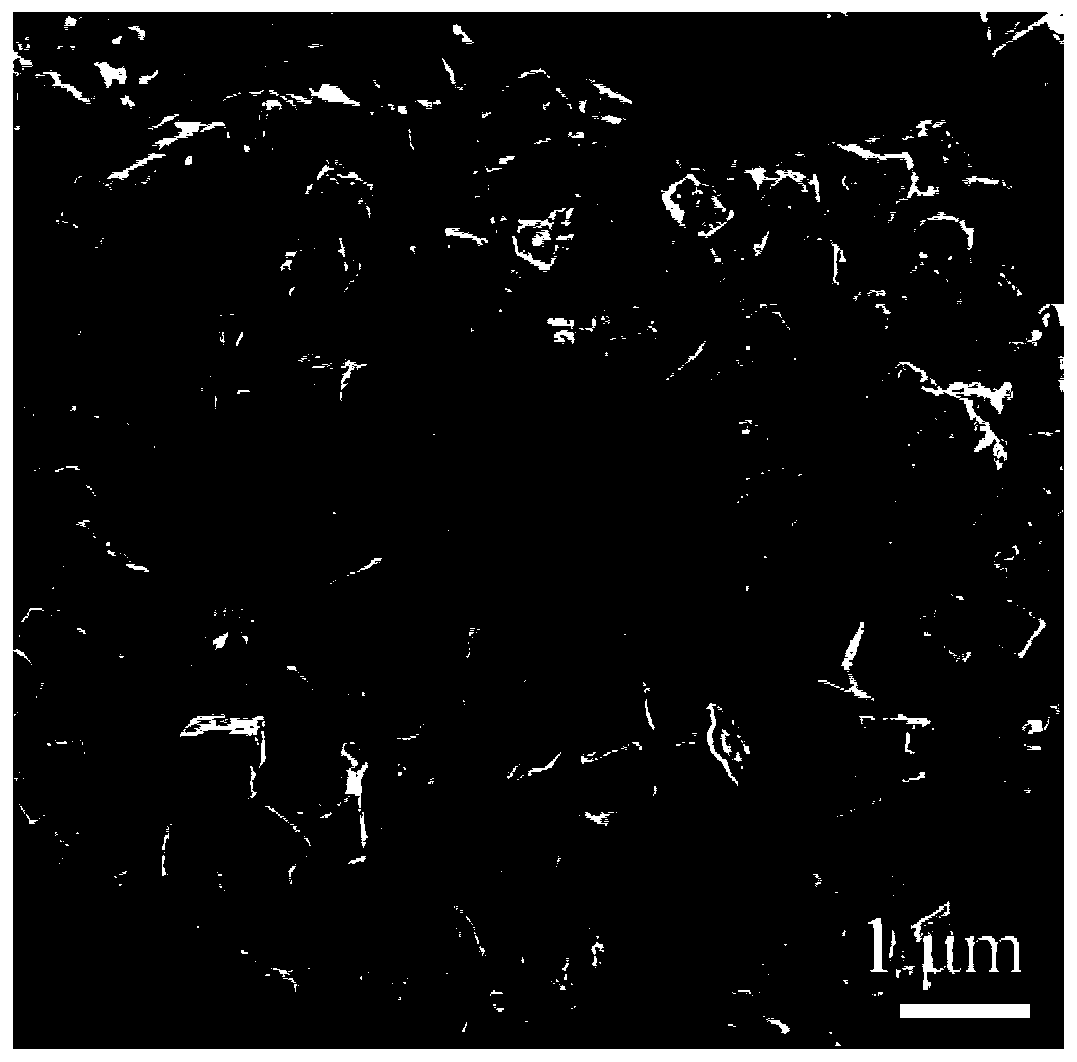

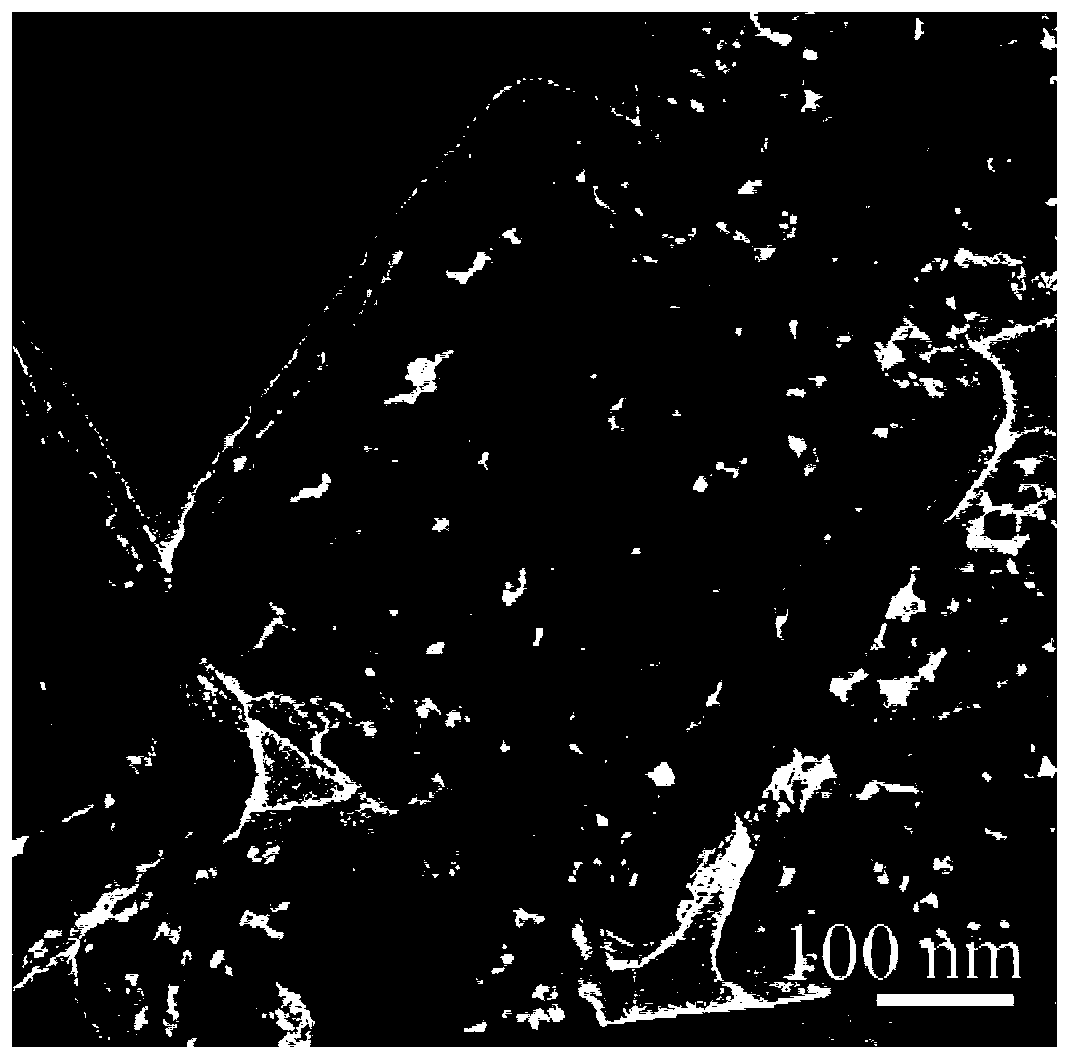

[0049] A method for preparing a cobalt selenide@carbon composite material for a negative electrode of a high-performance potassium ion battery, comprising the following steps:

[0050] Disperse 1.16g cobalt nitrate hexahydrate and 20mg cetyltrimethylammonium bromide in 40mL deionized water to form mixed solution A; disperse 18g 2-methylimidazole in 280mL deionized water to form mixed solution B; The mixed solution A was added to the mixed solution B, stirred and reacted for 20 minutes and then centrifuged, the centrifuged product was washed with ethanol three times, and then vacuum-dried at 80°C for 12 hours to obtain cobalt-based metal organic framework materials Co-MOFs with a cubic structure ; 0.2g of the obtained Co-MOFs is dispersed in a mixed solvent of 20mL ethanol and deionized water (the volume ratio of ethanol and deionized water is 3:7), and 0.23g cetyltrimethylammonium bromide is added , 0.035g resorcinol, 0.091g mass fraction of 25% ammonia and 0.065g mass fractio...

Embodiment 2

[0055] A method for preparing a cobalt selenide@carbon composite material for a negative electrode of a high-performance potassium ion battery, comprising the following steps:

[0056] Disperse 1.16g cobalt nitrate hexahydrate and 20mg cetyltrimethylammonium bromide in 40mL deionized water to form mixed solution A; disperse 18g 2-methylimidazole in 280mL deionized water to form mixed solution B; The mixed solution A was added to the mixed solution B, stirred and reacted for 20 minutes and then centrifuged, the centrifuged product was washed with ethanol three times, and then vacuum-dried at 80°C for 12 hours to obtain cobalt-based metal organic framework materials Co-MOFs with a cubic structure ; 0.2g of the obtained Co-MOFs is dispersed in a mixed solvent of 20mL ethanol and deionized water (the volume ratio of ethanol and deionized water is 3:7), and 0.23g cetyltrimethylammonium bromide is added , 0.035g resorcinol, 0.091g mass fraction of 25% ammonia and 0.065g mass fractio...

Embodiment 3

[0058] A method for preparing a cobalt selenide@carbon composite material for a negative electrode of a high-performance potassium ion battery, comprising the following steps:

[0059] Disperse 1.16g cobalt nitrate hexahydrate and 20mg cetyltrimethylammonium bromide in 40mL deionized water to form mixed solution A; disperse 18g 2-methylimidazole in 280mL deionized water to form mixed solution B; The mixed solution A was added to the mixed solution B, stirred and reacted for 20 minutes and then centrifuged, the centrifuged product was washed with ethanol three times, and then vacuum-dried at 80°C for 12 hours to obtain cobalt-based metal organic framework materials Co-MOFs with a cubic structure ; 0.2g of the obtained Co-MOFs is dispersed in a mixed solvent of 20mL ethanol and deionized water (the volume ratio of ethanol and deionized water is 3:7), and 0.23g cetyltrimethylammonium bromide is added , 0.048g pyrrole, 20mL of 0.1mol / L sodium persulfate solution, stirred for 8h, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com