Light curing composite for bone tissue engineering and bone tissue engineering bracket based on light curing composite

A technology of bone tissue engineering and composite materials, applied in the field of bone tissue engineering scaffolds and light-cured composite materials, can solve the problems of poor mechanical properties, biocompatibility and degradability of composite materials, serious cross-linking and exothermicity, etc., and achieve excellent mechanical properties. Properties and biological activity, reducing powder agglomeration, avoiding potential toxic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

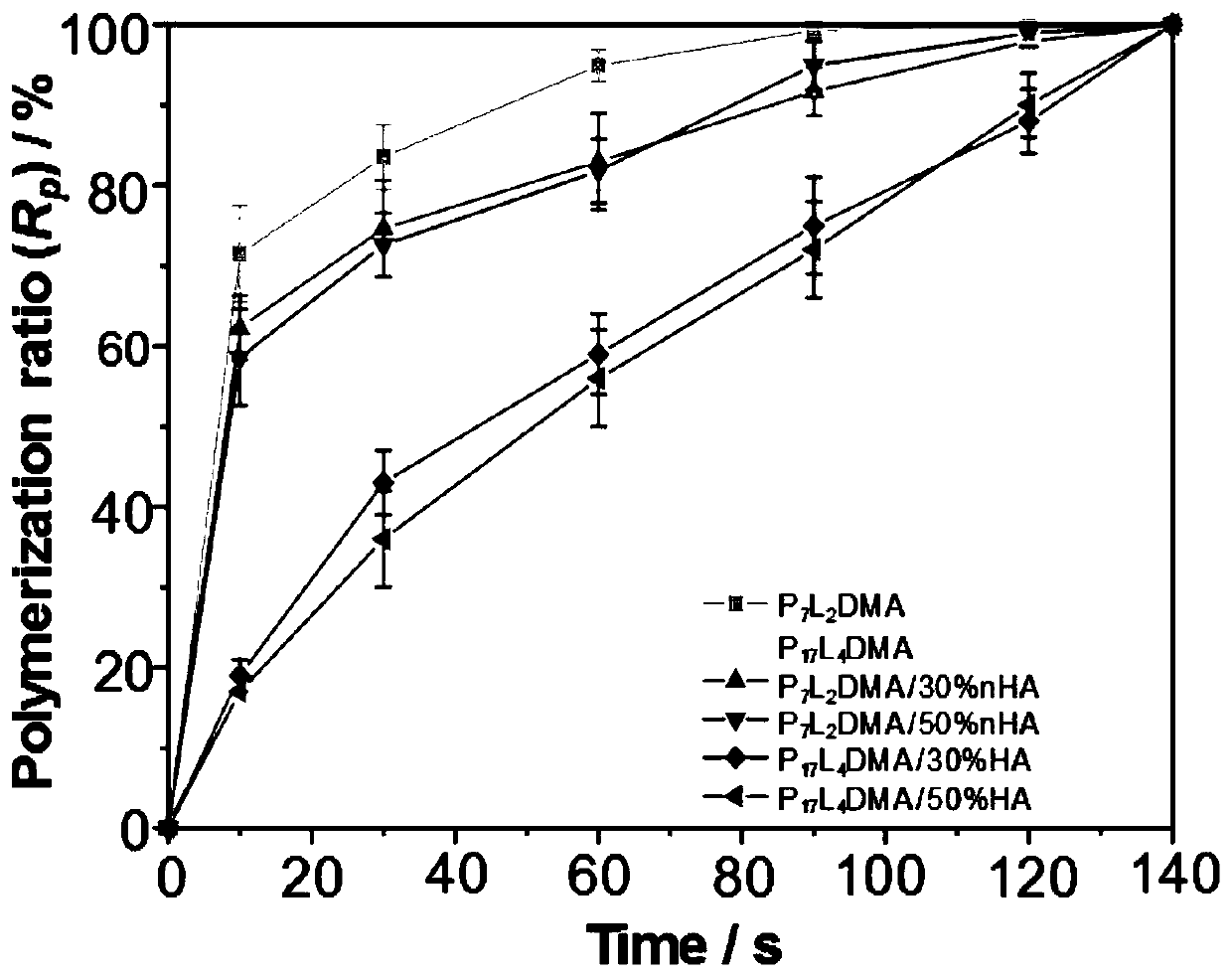

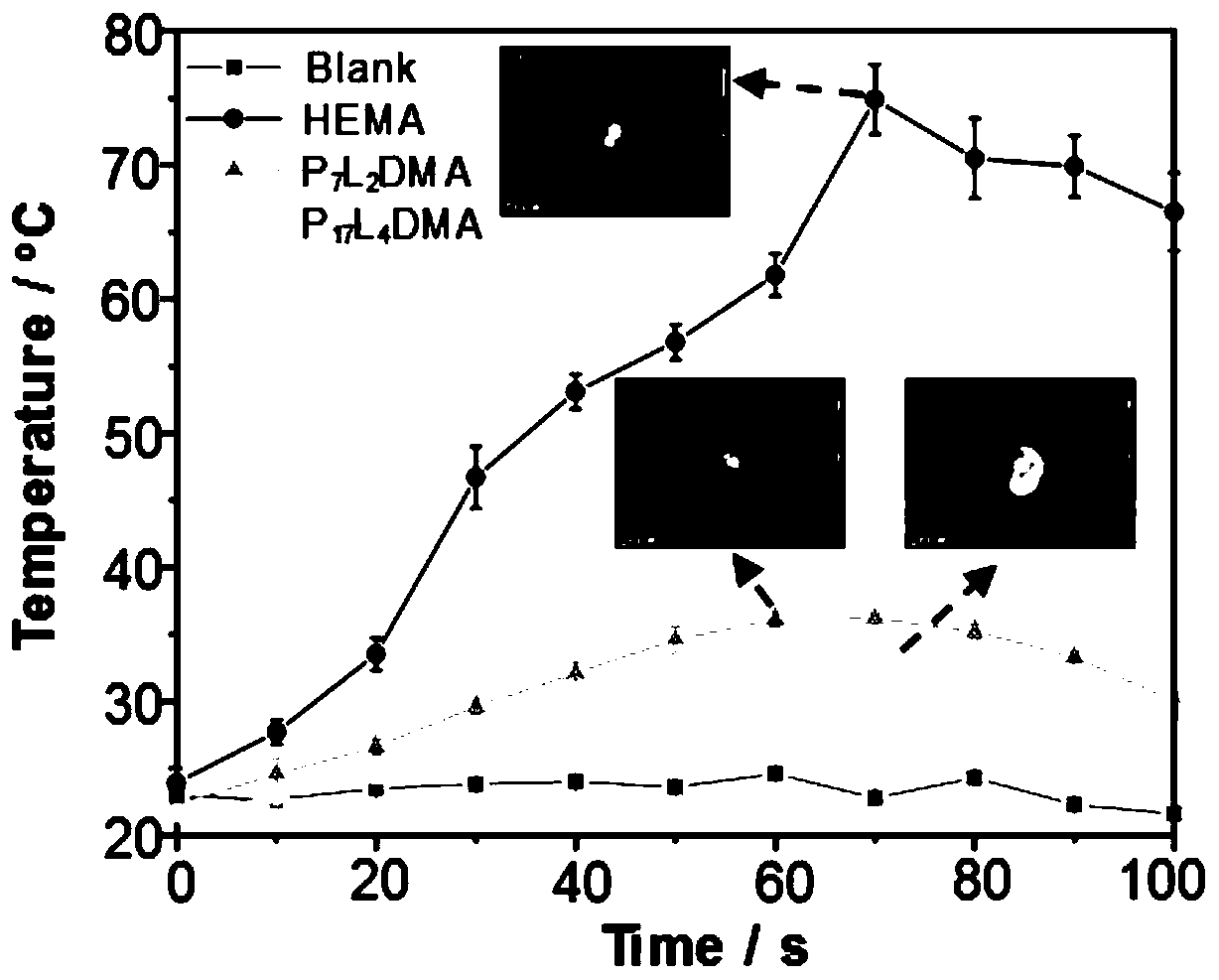

[0072] 1. Light-cured composite materials for bone tissue engineering

[0073] The above photocurable composite material for bone tissue engineering is obtained by photopolymerization of polylactide-propylene glycol dimethacrylate and hydroxyapatite, wherein:

[0074] Polylactide-Propylene Glycol Dimethacrylate is P 7 L 2 DMA;

[0075] The content of hydroxyapatite in the composite material is 30%;

[0076] The ultraviolet light intensity used in photopolymerization is 5.5mW / cm 2 .

[0077] 2. Scaffolds for bone tissue engineering based on the above-mentioned composite materials

[0078] The above-mentioned bone tissue engineering scaffold is prepared by the following method:

[0079] (a) Establish the STL file of the three-dimensional model of the composite material, and process the STL file according to the microstructure of the three-dimensional model, and then export the STL file;

[0080] (b) Import the STL file into the 3D printer;

[0081] (c) Mix polylactide-pr...

Embodiment 2

[0083] 1. Light-cured composite materials for bone tissue engineering

[0084] The above photocurable composite material for bone tissue engineering is obtained by photopolymerization of polylactide-propylene glycol dimethacrylate and hydroxyapatite, wherein:

[0085] Polylactide-Propylene Glycol Dimethacrylate is P 7 L 2 DMA;

[0086] The content of hydroxyapatite in the composite material is 50%.

[0087] The ultraviolet light intensity used in photopolymerization is 5.5mW / cm 2 .

[0088] 2. Scaffolds for bone tissue engineering based on the above-mentioned composite materials

[0089] The above-mentioned bone tissue engineering scaffold is prepared by the following method:

[0090] (a) Establish the STL file of the three-dimensional model of the composite material, and process the STL file according to the microstructure of the three-dimensional model, and then export the STL file;

[0091] (b) Import the STL file into the 3D printer;

[0092] (c) Mix polylactide-pr...

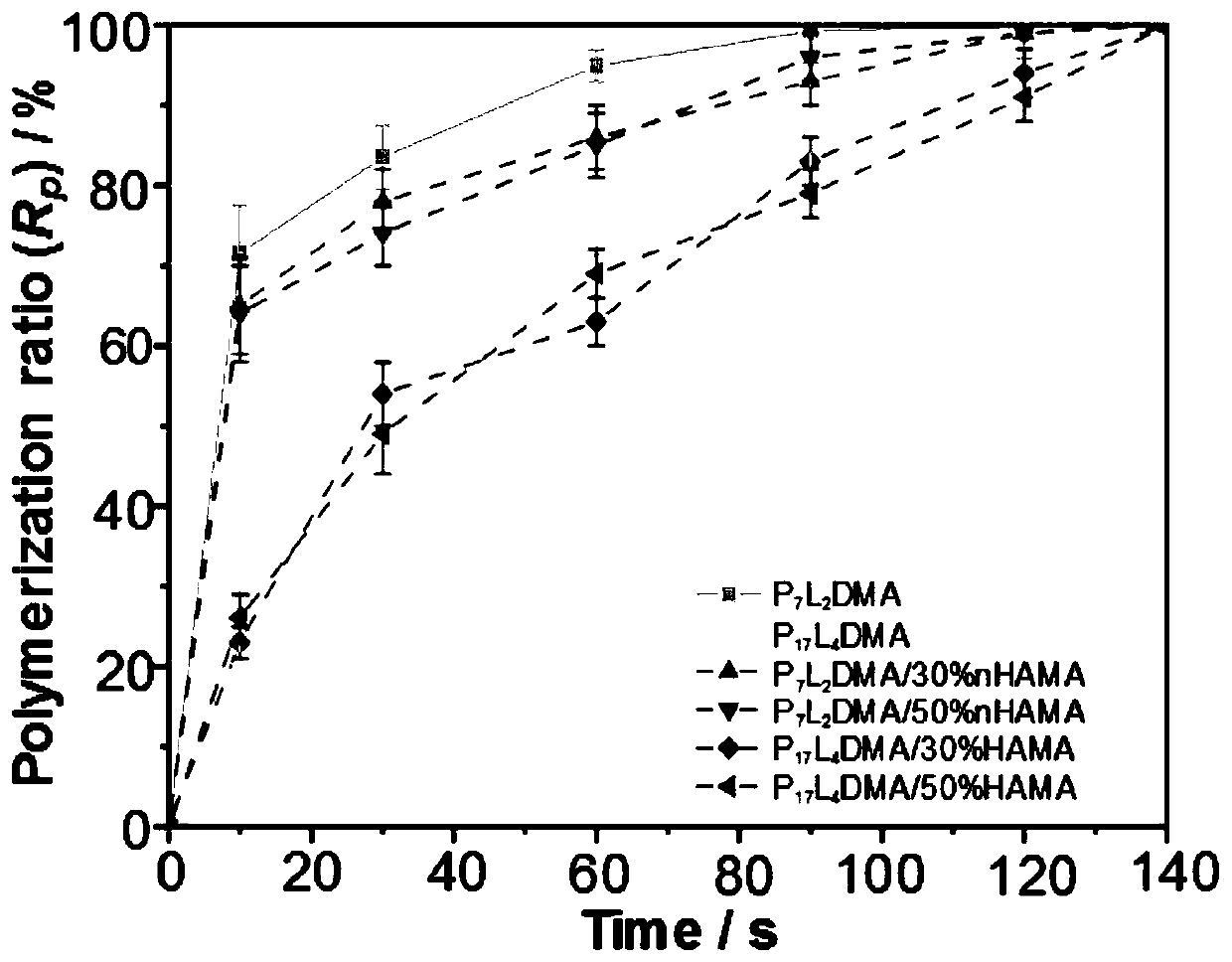

Embodiment 3

[0094] 1. Light-cured composite materials for bone tissue engineering

[0095] The above photocurable composite material for bone tissue engineering is obtained by photopolymerization of polylactide-propylene glycol dimethacrylate and hydroxyethyl methacrylate functionalized hydroxyapatite, wherein:

[0096] Polylactide-Propylene Glycol Dimethacrylate is P 7 L 2 DMA;

[0097] The content of hydroxyapatite functionalized with methacrylic acid hydroxyethyl in the composite material is 30%.

[0098] The ultraviolet light intensity used in photopolymerization is 5.5mW / cm 2 .

[0099] 2. Scaffolds for bone tissue engineering based on the above-mentioned composite materials

[0100] The above-mentioned bone tissue engineering scaffold is prepared by the following method:

[0101] (a) Establish the STL file of the three-dimensional model of the composite material, and process the STL file according to the microstructure of the three-dimensional model, and then export the STL fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap