High-tear-resistance cable material and preparation method thereof

A cable and high-resistance technology, which is applied in the field of high-tear-resistance cable materials and preparation, can solve problems such as narrow environmental adaptability, harsh cable use environment, poor oil resistance and wear resistance of cables, and achieve wide environmental adaptability and excellent mechanical properties , Excellent low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

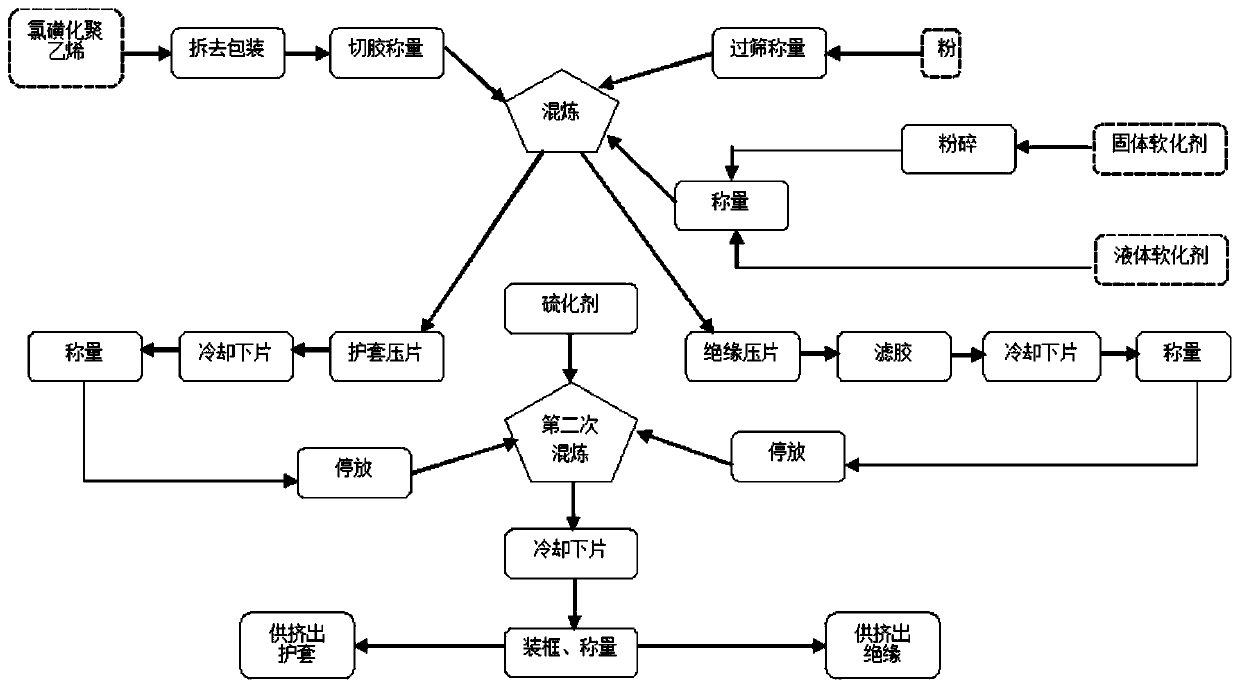

[0033] Such as figure 1 Therefore, the preparation method of the high tear-resistant cable material provided by the embodiment of the present invention includes:

[0034] Chlorosulfonated polyethylene plastication, adding magnesium oxide, calcium hydroxide, white carbon black, nano-scale calcium carbonate, chlorinated paraffin and antimony trioxide, low molecular polyethylene wax, paraffin, plasticizer to the internal mixer in sequence Mixing materials such as agent DOTP / DOA. Special attention: Since the specific gravity of white carbon black and nano calcium carbonate is very small, they cannot be added at one time, but should be mixed in three times according to the proportion. The mixed film needs to be placed (to ensure performance, the storage time should not be less than 24 hours).

[0035] Before the cable production, add vulcanizing agent DCP, accelerator TAIC, and coupling agent silicon-69 to the placed film for the second mixing, and then it can be used for extrusi...

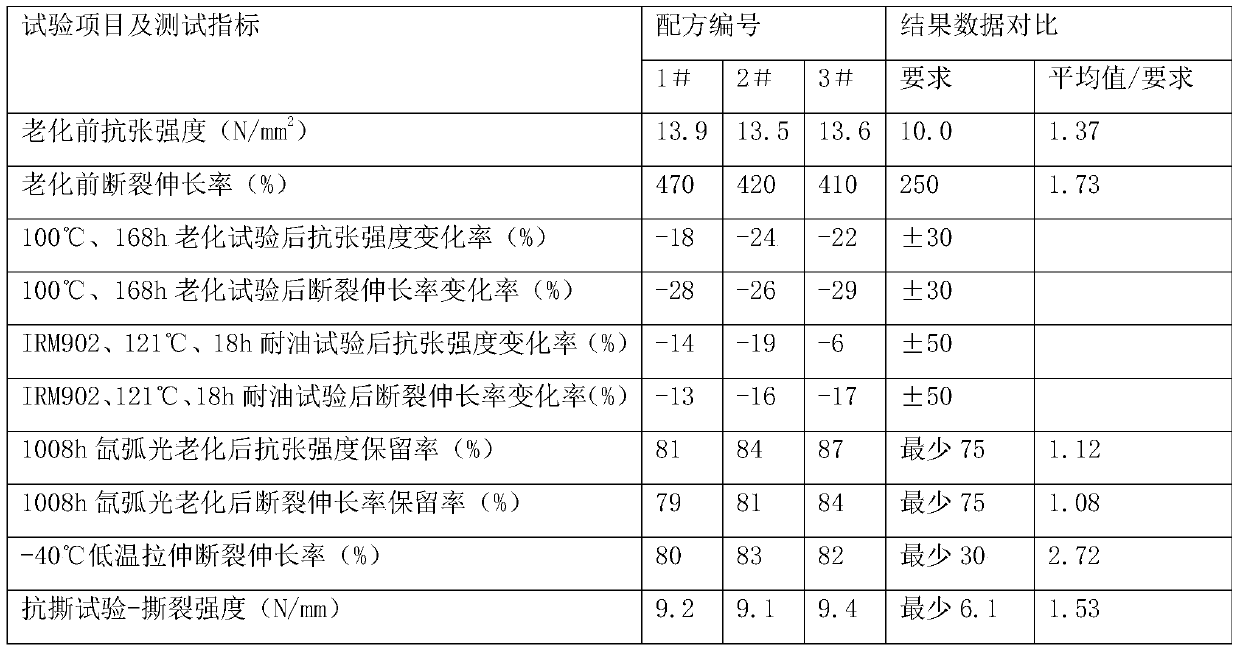

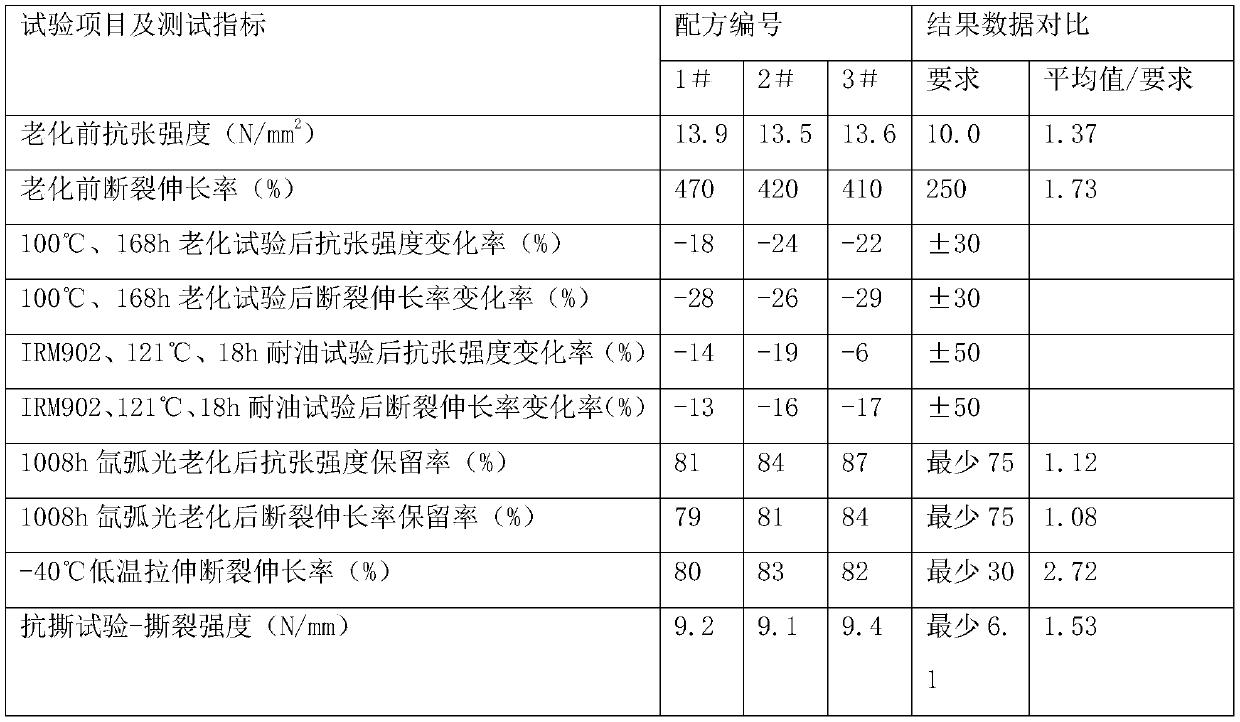

Embodiment 1

[0038] A kind of high tear resistance cable material provided by the embodiment of the present invention, its raw material comprises by mass parts (formulation 1#):

[0039] 100 parts of chlorosulfonated polyethylene, 15 parts of magnesium oxide, 25 parts of white carbon black, 28 parts of nano-scale calcium carbonate, 25 parts of chlorinated paraffin, 30 parts of calcium hydroxide, 1.0 parts of antioxidant RD, 6 parts of antimony trioxide , 5 parts of low molecular polyethylene wax; 2.5 parts of paraffin wax, 1.0 parts of coupling agent silicon-69, 4.5 parts of vulcanizing agent DCP, 7 parts of accelerator TAIC, and 4.5 parts of plasticizer DOTP / DOA.

Embodiment 2

[0041] A kind of high tear resistance cable material provided by the embodiment of the present invention, its raw material comprises by mass parts (formulation 2#):

[0042] 95 parts of chlorosulfonated polyethylene, 10 parts of magnesium oxide, 20 parts of white carbon black, 33 parts of nano-scale calcium carbonate, 20 parts of chlorinated paraffin, 25 parts of calcium hydroxide, 0.8 parts of anti-aging agent RD, 4 parts of antimony trioxide , 3.5 parts of low molecular polyethylene wax; 2 parts of paraffin wax, 0.8 parts of coupling agent silicon-69, 4.0 parts of vulcanizing agent DCP, 5 parts of accelerator TAIC, and 3.5 parts of plasticizer DOTP / DOA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com