Preparation method of network interpenetrating graphene-copper composite material

A technology of network interpenetrating and composite materials, which is applied in the field of preparation of network interpenetrating graphene-copper composite materials, which can solve the problems of different interfacial tension, poor dispersion, difficulty in uniform dispersion of graphene and strong interfacial bonding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

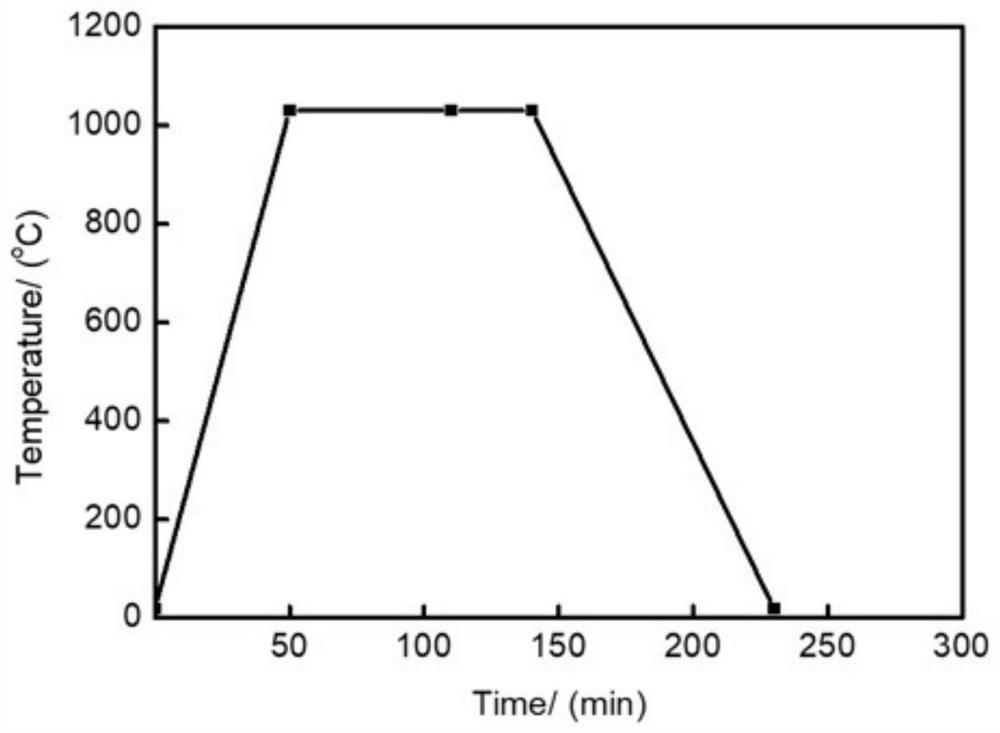

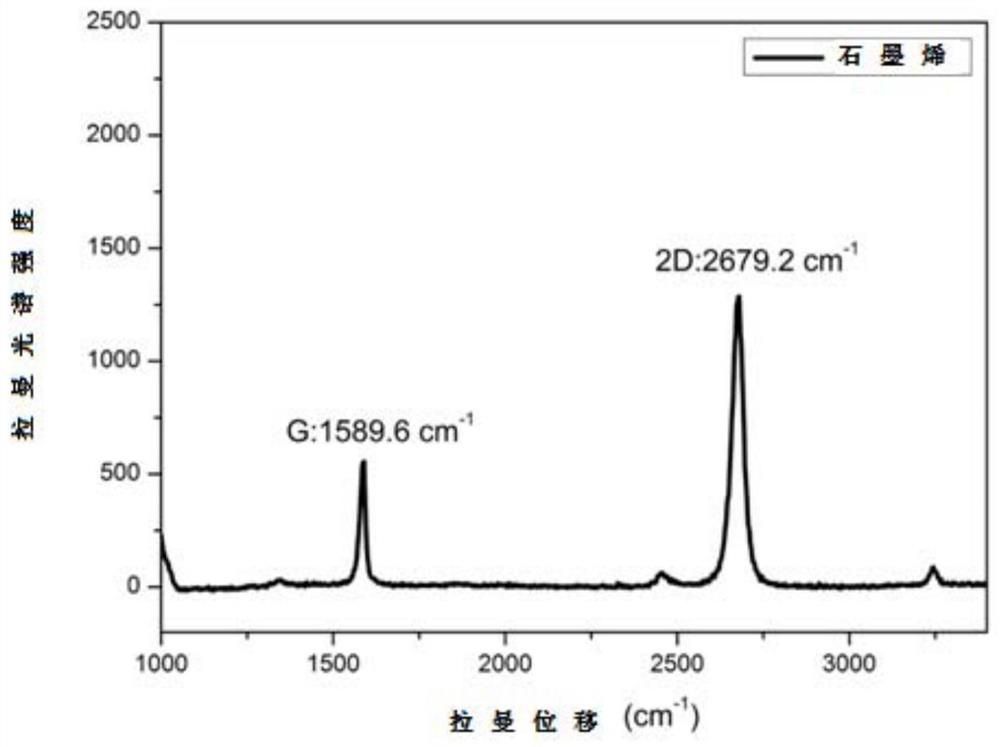

[0026] Embodiment 1 A kind of preparation method of network interpenetrating graphene-copper composite material X1

[0027] The method adopts pure copper granular powder as a base material, wherein the particle diameter of the granular powder is 50 microns. Using methane gas as the carbon source, chemical vapor deposition method (CVD method) is used to grow graphene in situ on the surface of copper powder. The specific process and parameters are as follows: put the copper powder in the container at room temperature and put it into the CVD furnace, and close the furnace tube. ;Use the vacuum pump to continuously extract the residual air in the furnace, then close the vacuum pump and feed the carrier gas, wherein the amount of argon is 200Sccm, and the amount of hydrogen is 25Sccm; figure 1 The temperature control method shown is for temperature regulation. Such as figure 1 As shown, heat up the CVD furnace environment at room temperature, raise the temperature to 1020°C for 5...

Embodiment 2

[0029] Embodiment 2 A kind of preparation method of network interpenetrating graphene-copper composite material X2

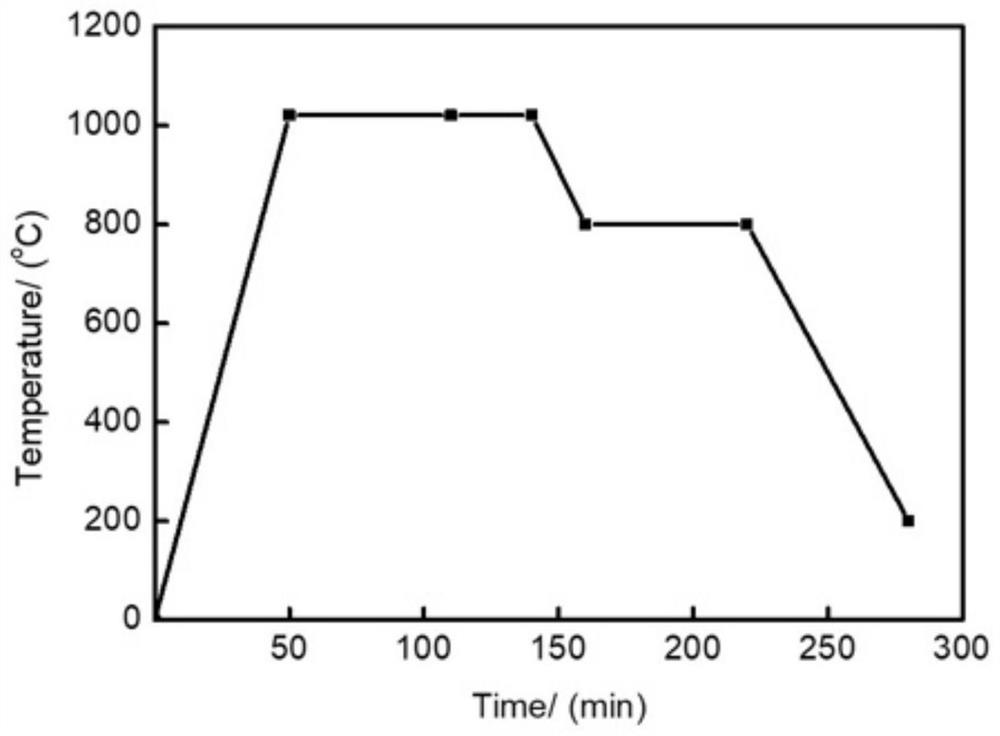

[0030]The method adopts copper-nickel alloy flake powder with a copper content of 75% as a base material. The thickness of the flake powder is 100 microns, the maximum length of the X-axis direction of the cross-section of the flake powder is 500 microns, and the maximum length of the Y-axis direction is 500 microns. Using acetylene gas as the carbon source, chemical vapor deposition method (CVD method) is used to grow graphene in situ on the surface of copper-nickel alloy powder. The specific process and parameters are as follows: put the copper-nickel alloy powder in a container at room temperature and put it in a CVD furnace , close the furnace tube; use the vacuum pump to continuously pump out the residual air in the furnace, then turn off the vacuum pump and feed the carrier gas, in which the amount of argon gas is 200Sccm, and the amount of hydrogen gas is...

Embodiment 3

[0032] Embodiment 3 A kind of preparation method of network interpenetrating graphene-copper composite material X3

[0033] The method adopts pure copper granular powder as a base material, wherein the particle diameter of the granular powder is 100 microns. Using ethanol liquid as carbon source, chemical vapor deposition method (CVD method) is used to grow graphene in situ on the surface of copper powder. ;Use the vacuum pump to continuously pump out the residual air in the furnace, then turn off the vacuum pump and feed the carrier gas, of which the amount of argon is 200Sccm, and the amount of hydrogen is 25Sccm; start to heat up at room temperature, raise the temperature to 1050°C in 30 minutes, keep the temperature for 30 minutes, and then at this temperature Put in carbon source ethanol, the amount of ethanol is 1mL / min, turn off the carbon source after incubation for 20min, and start to drop to room temperature in gradients. The time of the first cooling stage is 50 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com