Preparation method of reinforced copper-based composite wire

A copper-based composite, reinforced technology, applied in conductive materials, conductive materials, metal processing equipment and other directions, can solve the problems of graphene defects, large graphene specific surface area, graphene agglomeration, etc., to avoid dispersion and agglomeration problems, The effect of promoting the homogenization of composition and realizing electromechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 A preparation method of reinforced copper-based composite wire X1

[0030] The method adopts 99.9% pure copper granular powder as a base material, wherein the particle diameter of the granular powder is 75 μm. Specific steps are as follows:

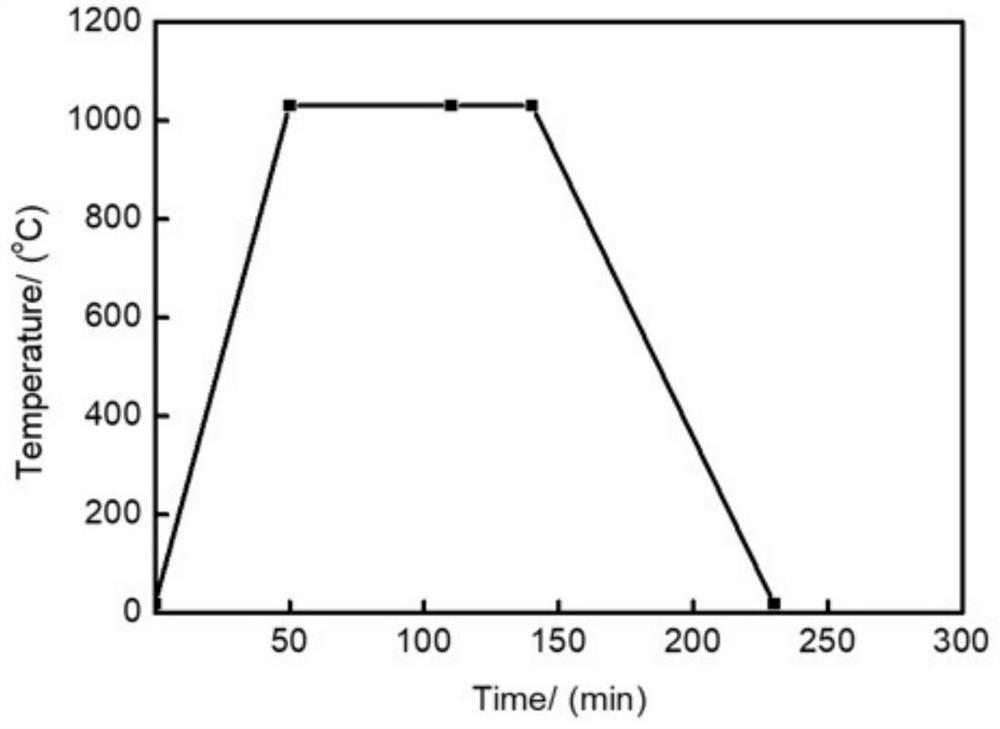

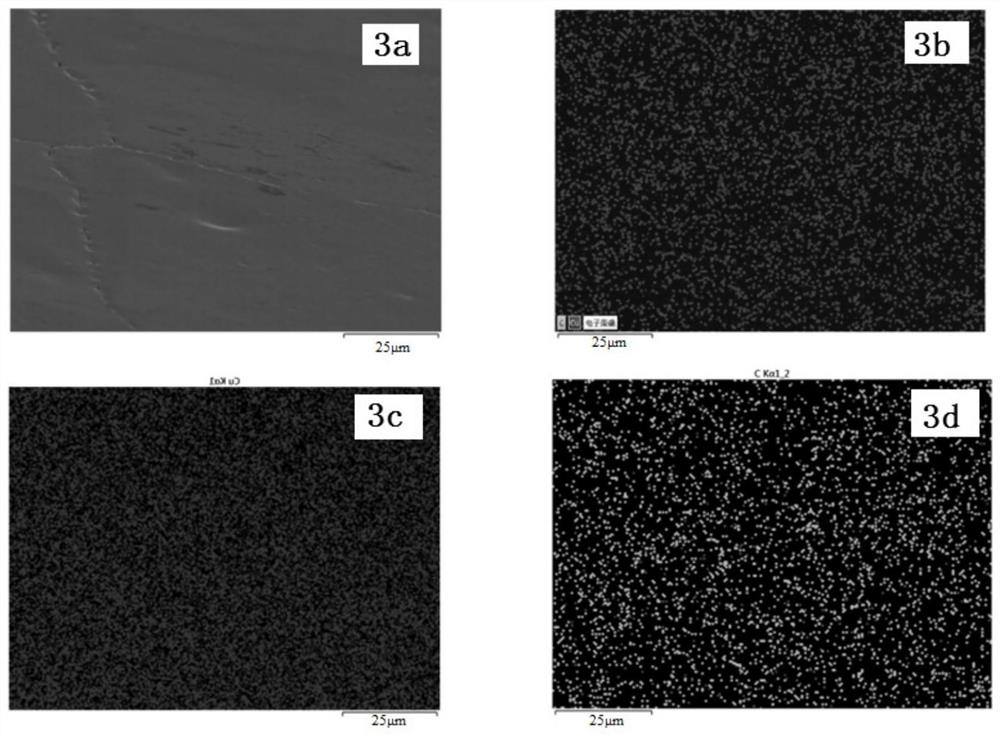

[0031] With methane (CH 4 ) gas as a carbon source, under low pressure conditions, adopt chemical vapor deposition method (CVD method) to grow graphene in situ on the surface of copper powder. Put the container into the CVD furnace and close the furnace tube; use the vacuum pump to continuously pump out the residual air in the furnace, then turn off the vacuum pump and feed the gas, in which the amount of argon is 200Sccm, and the amount of hydrogen is 25Sccm; start to heat up at room temperature, 50min to 1070°C, keep warm After 60 minutes, the carbon source was introduced, and the amount of methane introduced was 2 Sccm. After 30 minutes of growth, the carbon source was turned off, and the temperature began to drop. A...

Embodiment 2

[0039] Example 2 A preparation method of reinforced copper-based composite wire X2

[0040] The method uses 99.9% pure copper flake powder as the base material, wherein the thickness of the flake powder is 20 microns, the longest dimension of the cross-section in the X-axis direction is 50 microns, and the longest dimension of the cross-section in the Y-axis direction is 40 microns. Specific steps are as follows:

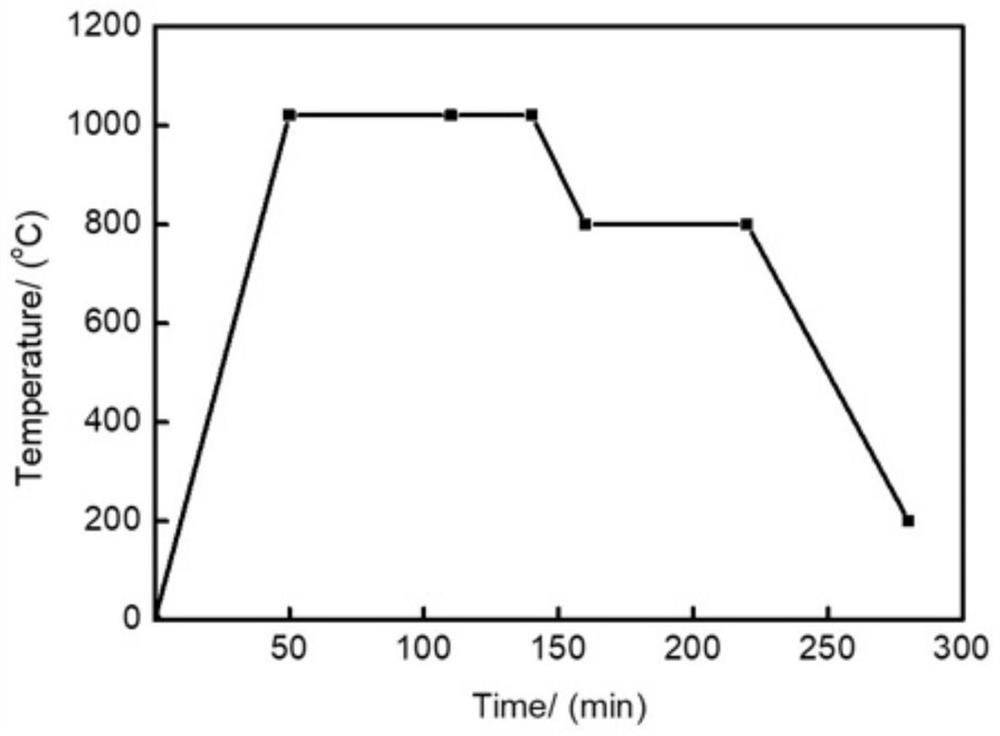

[0041] With acetylene (C 2 h 2 ) gas as a carbon source, under low pressure conditions, adopt the chemical vapor deposition method (CVD method) to grow graphene in situ on the surface of copper powder, the specific process is: put the granular copper powder in a suitable container, Put the container into the CVD furnace and close the furnace tube; use a vacuum pump to continuously pump out the residual air in the furnace and then introduce gas, of which the amount of argon is 200Sccm, and the amount of hydrogen is 25Sccm; start to heat up at room temperature, 50mi...

Embodiment 3

[0044] Example 3 A preparation method of reinforced copper-nickel-based composite wire X3

[0045] The invention uses copper-nickel alloy particles as the base material, wherein the particle size of the copper-aluminum alloy is 100 microns. Specific steps are as follows:

[0046] Using liquid ethanol as a carbon source, under low pressure conditions, the chemical vapor deposition method (CVD method) is used to grow graphene in situ on the surface of copper-nickel alloy powder. The specific process is: put the granular copper-nickel alloy powder into a suitable In the container, put the container into a CVD furnace at room temperature, and close the furnace tube; use a vacuum pump to continuously pump out the residual air in the furnace, then turn off the vacuum pump and feed in the gas, wherein the amount of argon is 200 Sccm, and the amount of hydrogen is 25 Sccm; start to heat up at room temperature, The temperature was raised to 1000°C in 40 minutes, and the constant tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com