SOI pressure sensor piezoresistor, manufacturing method thereof and SOI pressure sensor

A technology of pressure sensor and piezoresistor, which is applied in the manufacture/assembly of piezoelectric/electrostrictive devices, semiconductor/solid-state device manufacturing, piezoelectric/electrostrictive/magnetostrictive devices, etc., which can solve surface roughness, The stress cannot be effectively transmitted, and the uniformity of the ion beam cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

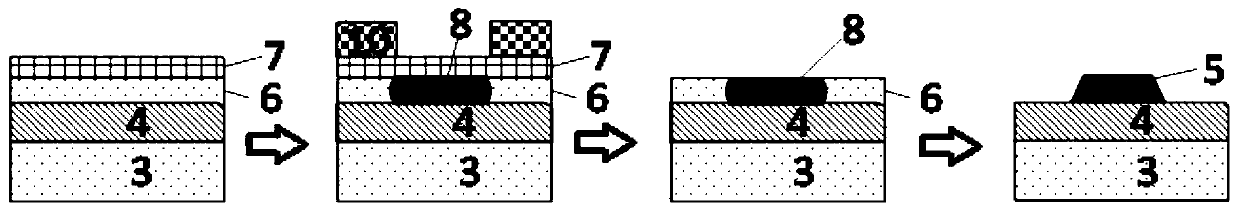

[0048] A kind of manufacturing method of SOI pressure sensor piezoresistor, its manufacturing process flow chart is as follows figure 1 shown, including the following steps:

[0049] (1) Prepare a buffer protection layer 7 on the surface of the top silicon 6 of the SOI sheet, specifically: grow a silicon dioxide film on the surface of the top silicon by thermal oxidation, with a thickness of 80 Å.

[0050] (2) The surface of the buffer protection layer 7 obtained in step (1) is subjected to uniform photolithography and development to prepare an injection barrier layer 10, exposing areas such as piezoresistors and interconnection pads, and using ion implantation to compress the top layer of silicon. P-type doping is performed on areas such as sensitive resistors and interconnection pads to form a P-type heavily doped region 8, wherein the average doping concentration in the P-type heavily doped region 8 is 2×10 20 cm -3 ; The non-P-type heavily doped region is N-type or P-typ...

Embodiment 2

[0056] A kind of manufacturing method of SOI pressure sensor piezoresistor, its manufacturing process flow chart is as follows Figure 4 shown, including the following steps:

[0057] (1) Prepare a buffer protection layer 7 on the surface of the top silicon 6 of the P-type SOI sheet, specifically: grow a silicon dioxide film on the surface of the top silicon by thermal oxidation, with a thickness of 100 Å.

[0058] (2) Perform P-type doping on the top layer of silicon prepared with buffer protection layer 7 on the surface in step (1) by diffusion doping, and anneal to form P-type heavily doped region 8 . In this step, when the difference in doping concentration between the P-type non-doped region and the P-type heavily doped region is small, for example, the doping concentration of the non-P-type heavily doped region is 1×10 18 cm -3 , P-type heavily doped region concentration 3×10 18 cm -3 When , or when the entire top silicon layer is heavily doped with P type, the diffe...

Embodiment 3

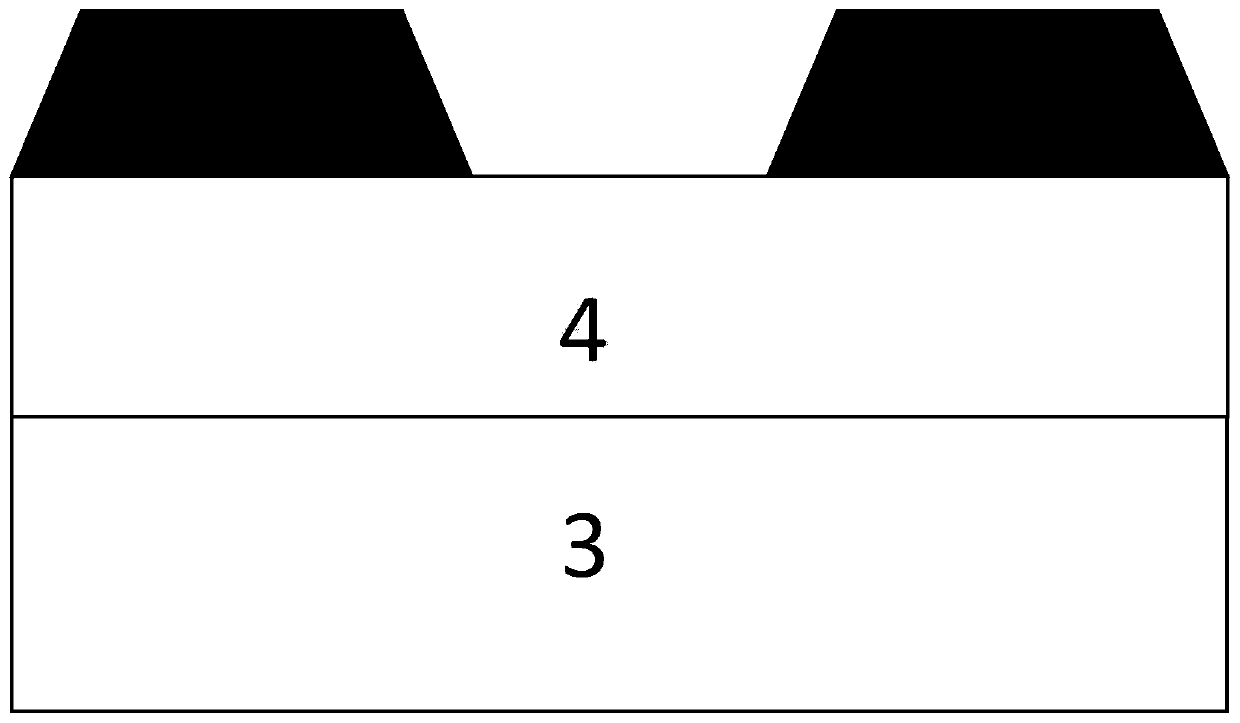

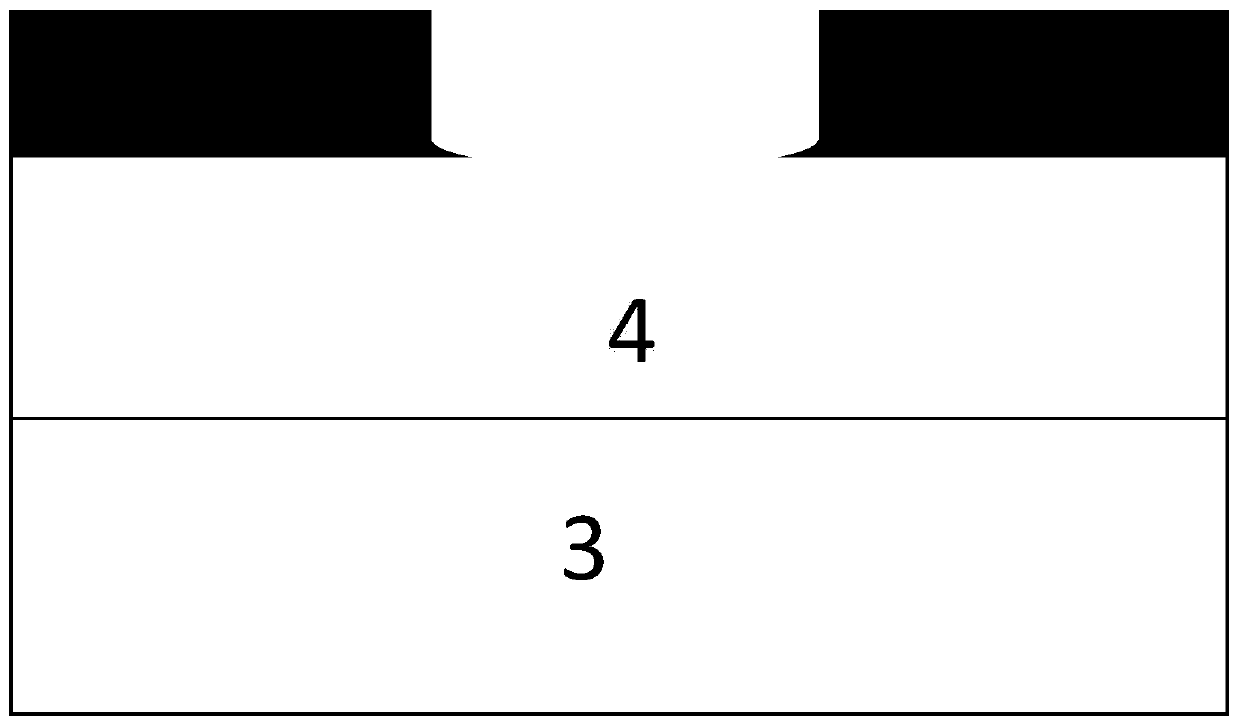

[0066] An SOI pressure sensor such as Figure 5 As shown, it includes a substrate sheet 1 and a functional chip 3, a BOX layer 4, and a P-type heavily doped piezoresistor 5 arranged sequentially on the substrate sheet from bottom to top, wherein a stress reference cavity 2 is also included between the substrate sheet and the functional chip. , P-type heavily doped piezoresistor 5 is the SOI pressure sensor piezoresistor prepared in Example 1.

[0067] In this embodiment, the substrate chip 1 is a bonded silicon chip; the functional chip 3 is an N-type silicon chip, and the doping concentration is less than 1×10 18 cm -3 ; The stress reference cavity 2 is a stress reference cavity of a vacuum pressure sensor, and its cavity structure is a C-shaped strain cavity structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Doping concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com