Lithium anode-protecting polymer layer for a lithium metal secondary battery and manufacturing method

A lithium secondary battery and polymer technology, applied in secondary batteries, lithium batteries, battery electrodes, etc., can solve problems such as no plausible solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

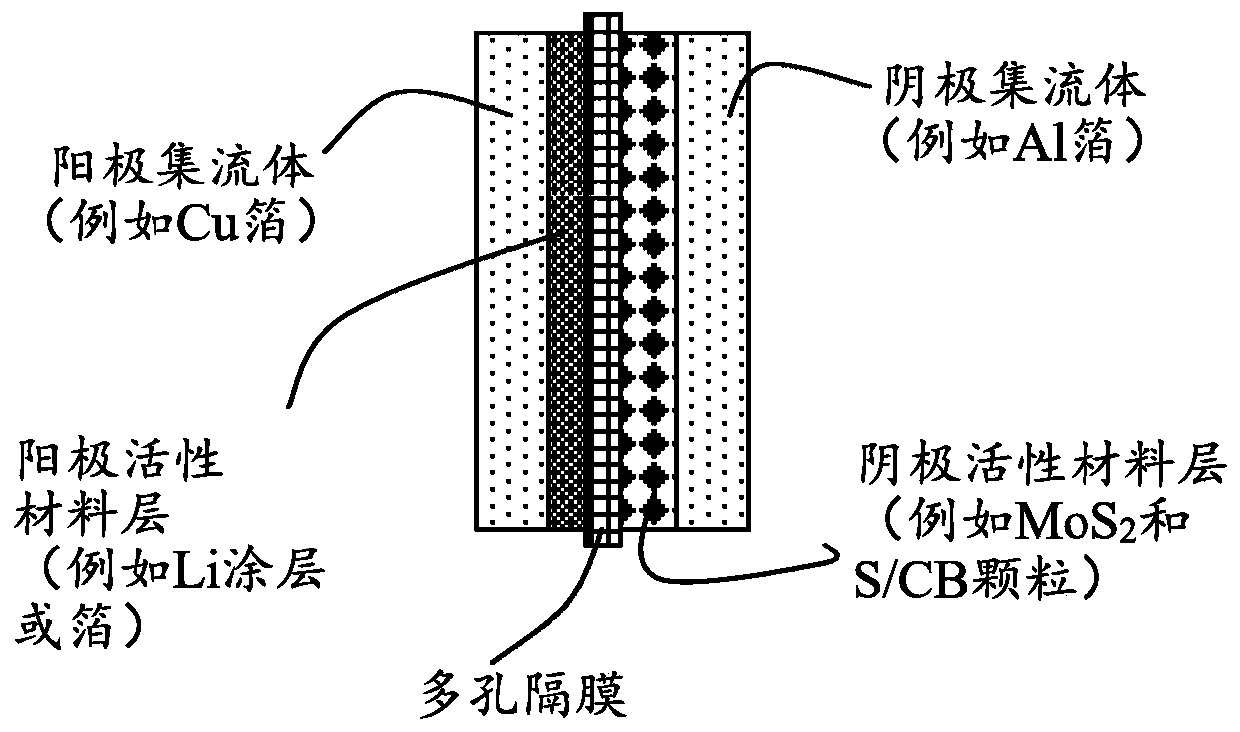

[0104] Example 1: Lithium anode with elastic polymer protection and V 2 o 5 Granular Cathode for Lithium Batteries

[0105] respectively by V 2 o 5 V surrounded by particles and graphene 2 o 5 The particles prepare the cathode active material layer. V 2 o 5 Pellets are commercially available. V surrounded by graphene 2 o 5 Granules are prepared in-house. In a typical experiment, by placing V 2 o 5Mix in an aqueous LiCl solution to obtain a vanadium pentoxide gel. The Li+ exchanged gel obtained by interaction with LiCl solution (Li:V molar ratio kept at 1:1) was mixed with GO suspension and then placed in a Teflon-lined stainless steel 35 ml autoclave, sealed, and heated up to 180° C. for 12 h. After this hydrothermal treatment, the green solid was collected, washed thoroughly, sonicated for 2 min, and dried at 70 °C for 12 h, then mixed with another 0.1% GO in water, sonicated to break down the nanoribbon size, and It was then spray-dried at 200 °C to obtain gr...

example 2

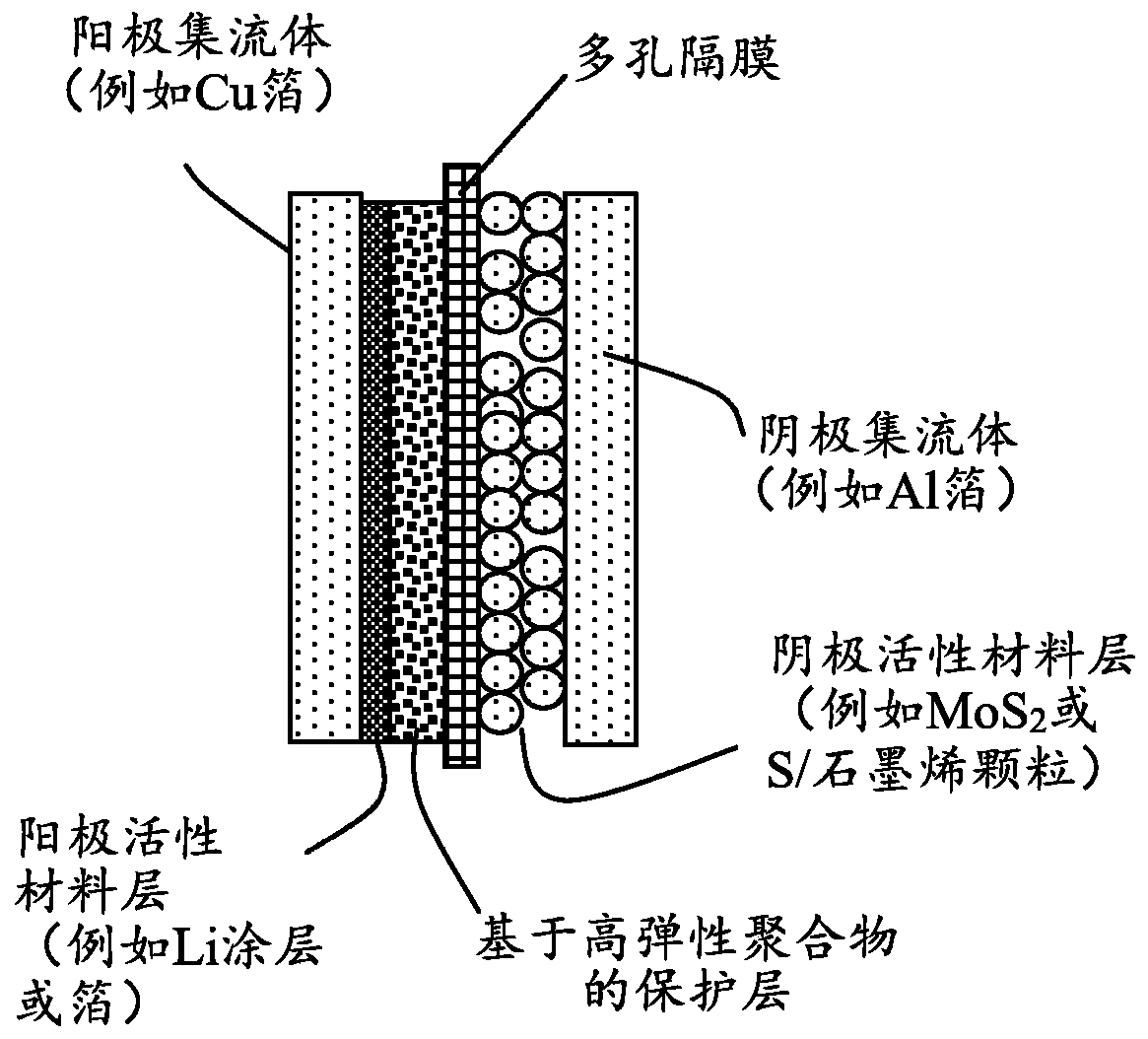

[0113] Example 2: High Elastic Polymer in Li-LiCoO 2 Implementation in the anode of a cell (originally said cell does not contain lithium)

[0114] The highly elastic polymer used for anode protection is based on cationic polymerization and crosslinking of cyanoethyl polyvinyl alcohol (PVA-CN) in succinonitrile (SN). The procedure starts with dissolving PVA-CN in succinonitrile to form a mixture solution. This step is followed by the addition of an initiator to the solution. For the purpose of incorporating some lithium species into the elastomeric polymer, we choose to use LiPF 6 as an initiator. LiPF 6 The ratio to the PVA-CN / SN mixture solution was varied from 1 / 20 to 1 / 2 by weight to form a series of precursor solutions. Subsequently, these solutions were separately spray-deposited onto the lithium foil surface to form thin layers of precursor reactive species. The precursor reactive mass is then heated at a temperature from 75°C to 100°C for 2 to 8 hours to obtain a...

example 3

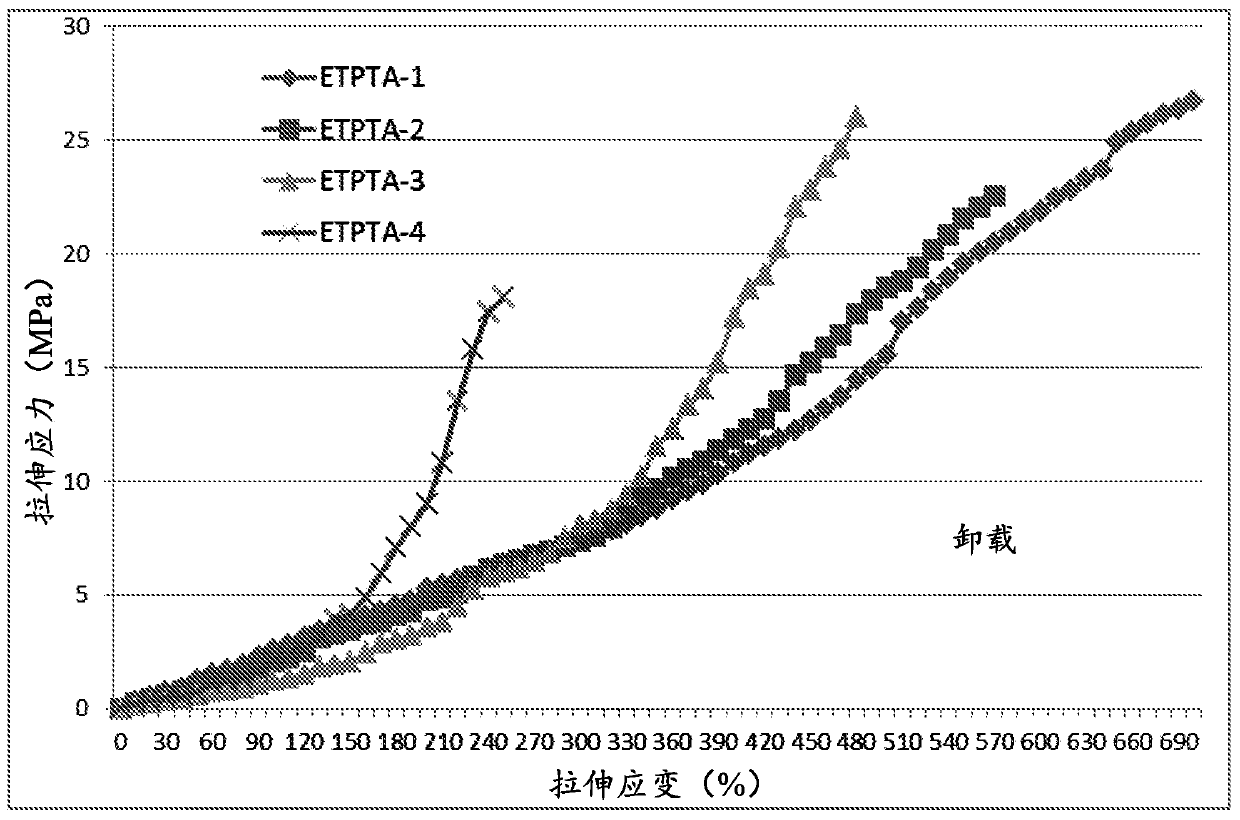

[0117] Example 3: Li Metal Cell Containing Metal Fluoride Nanoparticle-Based Cathode and PETEA-Based Highly Elastic Polymer Protected Li Anode

[0118] For acting as an anode lithium metal protective layer, pentaerythritol tetraacrylate (PETEA) (Formula 3) was used as monomer:

[0119]

[0120] In a representative procedure, the precursor solution was composed of 1.5 wt.% PETEA dissolved in a solvent mixture of 1,2-dioxolane (DOL) / dimethoxymethane (DME) (1:1 by volume). (C 17 h 20 o 8 ) monomer and 0.1wt.% azobisisobutyronitrile (AIBN, C 8 h 12 N 4 ) Initiator composition. The PETEA / AIBN precursor solution was cast onto a Li metal layer pre-deposited on the surface of Cu foil to form a precursor film, which was polymerized and cured at 70 °C for half an hour to obtain a lightly cross-linked polymer .

[0121] Additionally, the reactive mass PETEA / AIBN (without conductive additives) was cast onto a glass surface to form several films, which were polymerized and cured...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionic conductivity | aaaaa | aaaaa |

| ionic conductivity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com