Preparation method and application of magnetic MOF-based bisphenol A molecularly imprinted high-selectivity nano composite material

A nanocomposite material and molecular imprinting technology, which is applied in the field of preparation of magnetic MOF-based bisphenol A molecularly imprinted high-selectivity nanocomposite materials, can solve the problems of easy embedding of recognition sites, affecting material adsorption capacity and adsorption rate, etc. , to achieve the effect of simplifying the pre-treatment process, reducing the cost of testing, and facilitating recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

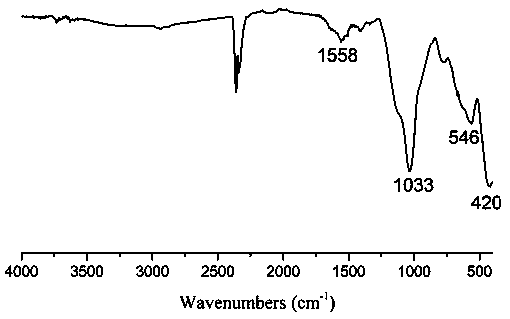

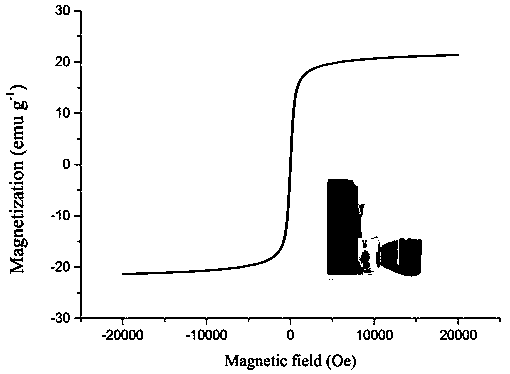

[0039] A method for preparing a magnetic MOF-based bisphenol A molecularly imprinted highly selective nanocomposite material, the steps of which are:

[0040] (1) Add 10 mmol FeCl 3 , 2.5 mmol of sodium citrate and 50 mmol of sodium acetate were added to 100 mL of ethylene glycol solution, dissolved and mixed evenly, then transferred to a high-temperature reaction kettle, kept at 200°C for 10 hours, cooled to room temperature after the reaction, and washed with pure water and anhydrous water respectively. Washed with ethanol, the resulting black product Fe 3 o 4 Particles are dry and ready for use;

[0041] (2) Add 200 mg Fe 3 o 4 The particles were ultrasonically dispersed in 50 mL of 50% ethanol solution, 2 mmol of zinc nitrate and 30 mmol of 2-methylimidazole were added, ultrasonically reacted at room temperature for 10 min, washed with ethanol and water, magnetically separated and dried to obtain the magnetic MOF material Fe 3 o 4 @ZIF-8, disperse it in ethanol solut...

Embodiment 2

[0044] A method for preparing a magnetic MOF-based bisphenol A molecularly imprinted highly selective nanocomposite material, the steps of which are:

[0045] (1) Add 10 mmol FeCl 3 , 2.5 mmol of sodium citrate and 50 mmol of sodium acetate were added to 100 mL of ethylene glycol solution, dissolved and mixed evenly, then transferred to a high-temperature reaction kettle, kept at 200°C for 10 hours, cooled to room temperature after the reaction, and washed with pure water and anhydrous water respectively. Washed with ethanol, the resulting black product Fe 3 o 4 Particles are dry and ready for use;

[0046] (2) Add 200 mg Fe 3 o 4 The particles were ultrasonically dispersed in 50 mL of 50% ethanol solution, 2 mmol of zinc nitrate and 30 mmol of 2-methylimidazole were added, ultrasonically reacted at room temperature for 10 min, washed with ethanol and water, magnetically separated and dried to obtain the magnetic MOF material Fe 3 o 4 @ZIF-8, dispersed in ethanol solutio...

Embodiment 3

[0051] A method for preparing a magnetic MOF-based bisphenol A molecularly imprinted highly selective nanocomposite material, the steps of which are:

[0052] (1) Add 10 mmol FeCl 3 , 2.5 mmol of sodium citrate and 50 mmol of sodium acetate were added to 100 mL of ethylene glycol solution, dissolved and mixed evenly, then transferred to a high-temperature reaction kettle, kept at 200°C for 10 hours, cooled to room temperature after the reaction, and washed with pure water and anhydrous water respectively. Washed with ethanol, the resulting black product Fe 3 o 4 Particles are dry and ready for use;

[0053] (2) Add 200 mg Fe 3 o 4 The particles were ultrasonically dispersed in 50 mL of 50% ethanol solution, 2 mmol of zinc nitrate and 30 mmol of 2-methylimidazole were added, ultrasonically reacted at room temperature for 10 min, washed with ethanol and water, magnetically separated and dried to obtain the magnetic MOF material Fe 3 o 4 @ZIF-8, dispersed in ethanol solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com