A kind of laser spot welding machine and the production process of range hood using the laser spot welding machine

A technology of laser spot welding and range hood, which is used in laser welding equipment, welding/welding/cutting items, welding equipment, etc. Affect welding efficiency and other problems, to reduce the possibility of unwelding, reduce the use of motors, and reduce the size of crystal grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

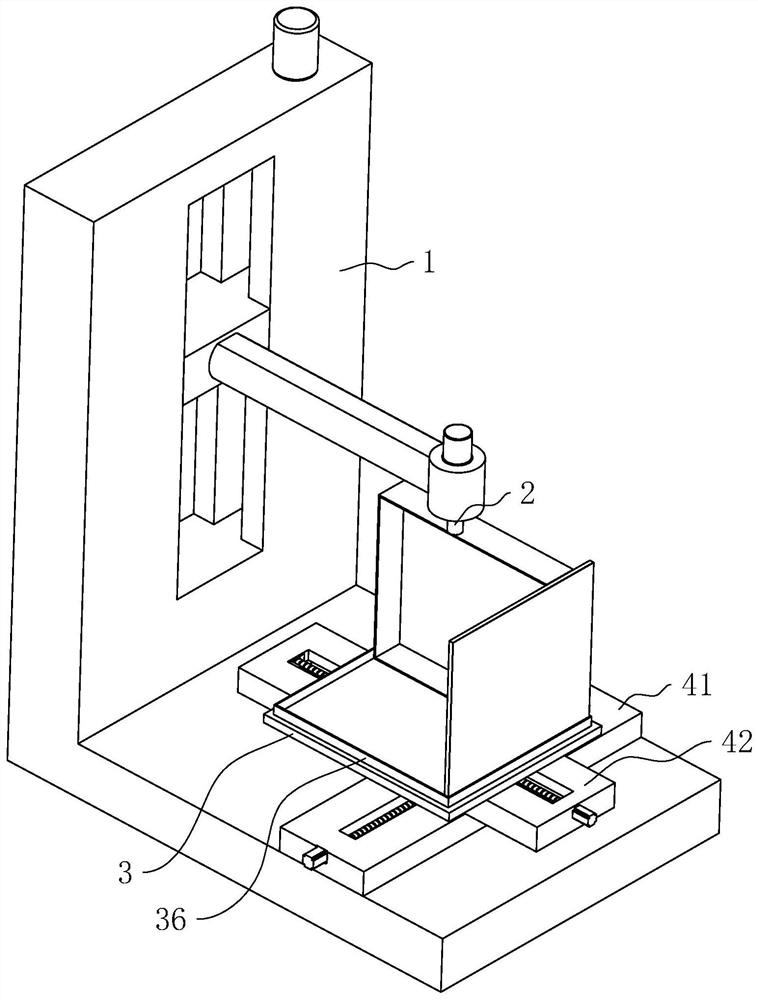

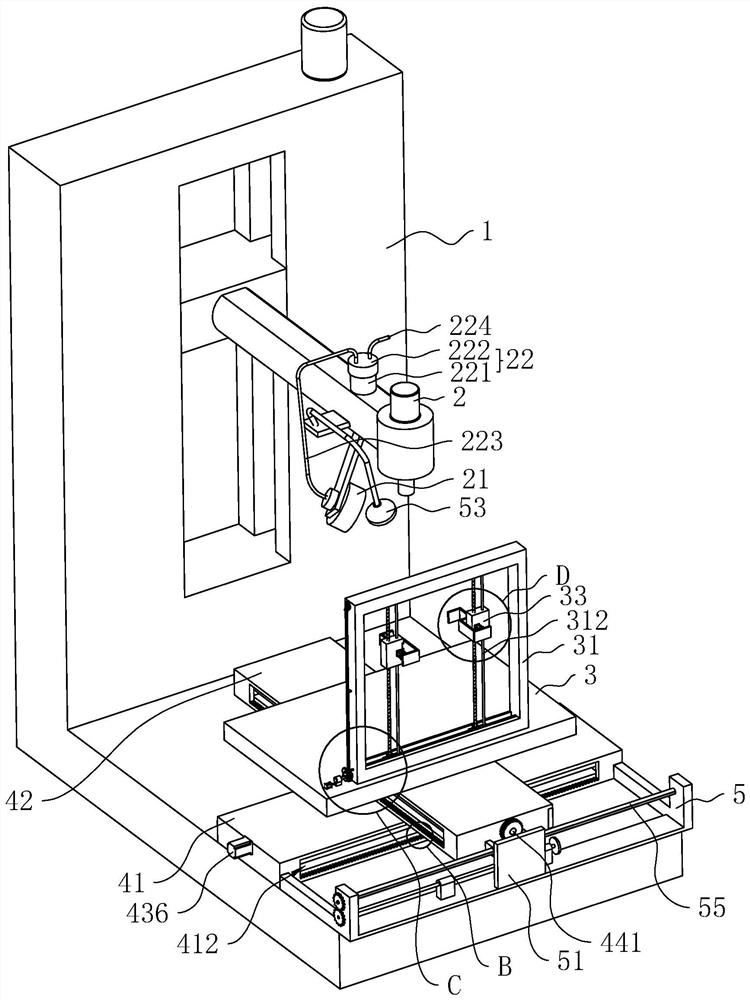

[0079] refer to figure 2 , a kind of laser spot welding machine, comprises frame 1, is provided with laser device 2, observation mechanism, moving mechanism on frame 1, is provided with workbench 3 on the moving mechanism, and laser device 2 is used for welding weldment, and observation mechanism provides staff Check the welding position, the moving mechanism drives the workbench 3 to move to realize the welding of the laser 2 to the weldment, and the workbench 3 is provided with a clamping mechanism for clamping the weldment.

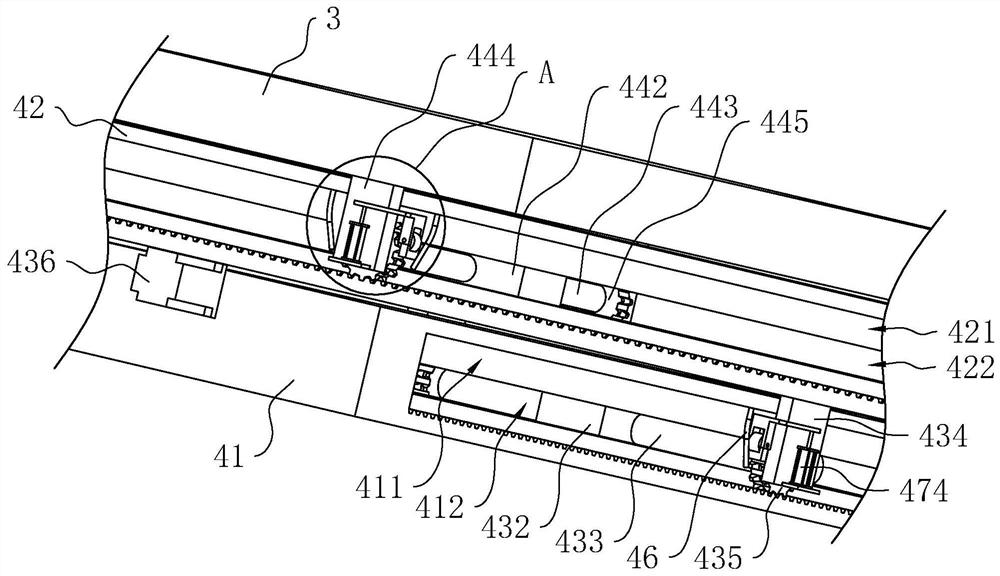

[0080] refer to figure 2 with image 3 , the moving mechanism includes a horizontal adjustment frame 41 and a longitudinal adjustment frame 42, the horizontal adjustment frame 41 is fixedly arranged on the frame 1, the longitudinal adjustment frame 42 is slidingly arranged on the horizontal adjustment frame 41, and the horizontal adjustment frame 41 is provided with a The fourth drive assembly connected to the adjustment frame 42 , the worktable 3 ...

Embodiment 2

[0112] A production process of range hood, comprising the following process steps:

[0113] S1: Cut stainless steel raw materials with a cutting machine to obtain raw material composite plates;

[0114] S2: Bending and stamping the raw material combination board with a punching machine to obtain the finished combination board;

[0115] S3: Pre-treat the welding surface of the composite board first, then assemble the finished composite board, and weld the composite board with the laser spot welding machine in Embodiment 1, and form a primary welding seam at the welding place of the composite board to obtain a semi-finished range hood;

[0116] The preprocessing steps are as follows:

[0117] Step a: Clean the welding surface of the finished composite board with a hot lye solution with a pH of 8-9 and a temperature of 50-60°C, then rinse with deionized water, and dry for use;

[0118] Step b: spray welding strengthening agent on the welding surface with a high-pressure air spr...

Embodiment 1

[0125] The difference between Examples 18-22 and Example 1 is that each component in the active agent is calculated in the following table by weight percentage.

[0126] Example sodium fluoride calcium fluoride silica acetone Example 18 13.75 8 5.75 72.5 Example 19 12.5 7 6.5 75 Example 20 11.25 6 7.25 77.5 Example 21 10 5 8 80 Example 22 11 9 5 75

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com