Prussian blue material, and preparation method and application thereof

A technology of Prussian blue and reaction, applied in the direction of structural parts, electrical components, metal cyanide, etc., can solve the problems of affecting the cycle life and low actual capacity, and achieve the effect of long cycle life, high capacity and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Dissolve sodium ferrocyanide decahydrate in 50 ml of deionized water, stir evenly to obtain solution I with a concentration of 0.06 mol / L; dissolve ferrous sulfate, ascorbic acid, and sodium citrate in 50 ml of deionized water to obtain the concentration Solution II of 0.066mol / L, 0.04mol / L, and 1.4mol / L respectively; Add solution I and solution II to 100ml deionized water at the same time, and undergo co-precipitation reaction at 20℃, then wash and centrifuge Na is obtained after separation and vacuum drying x FeFe(CN) 6 .

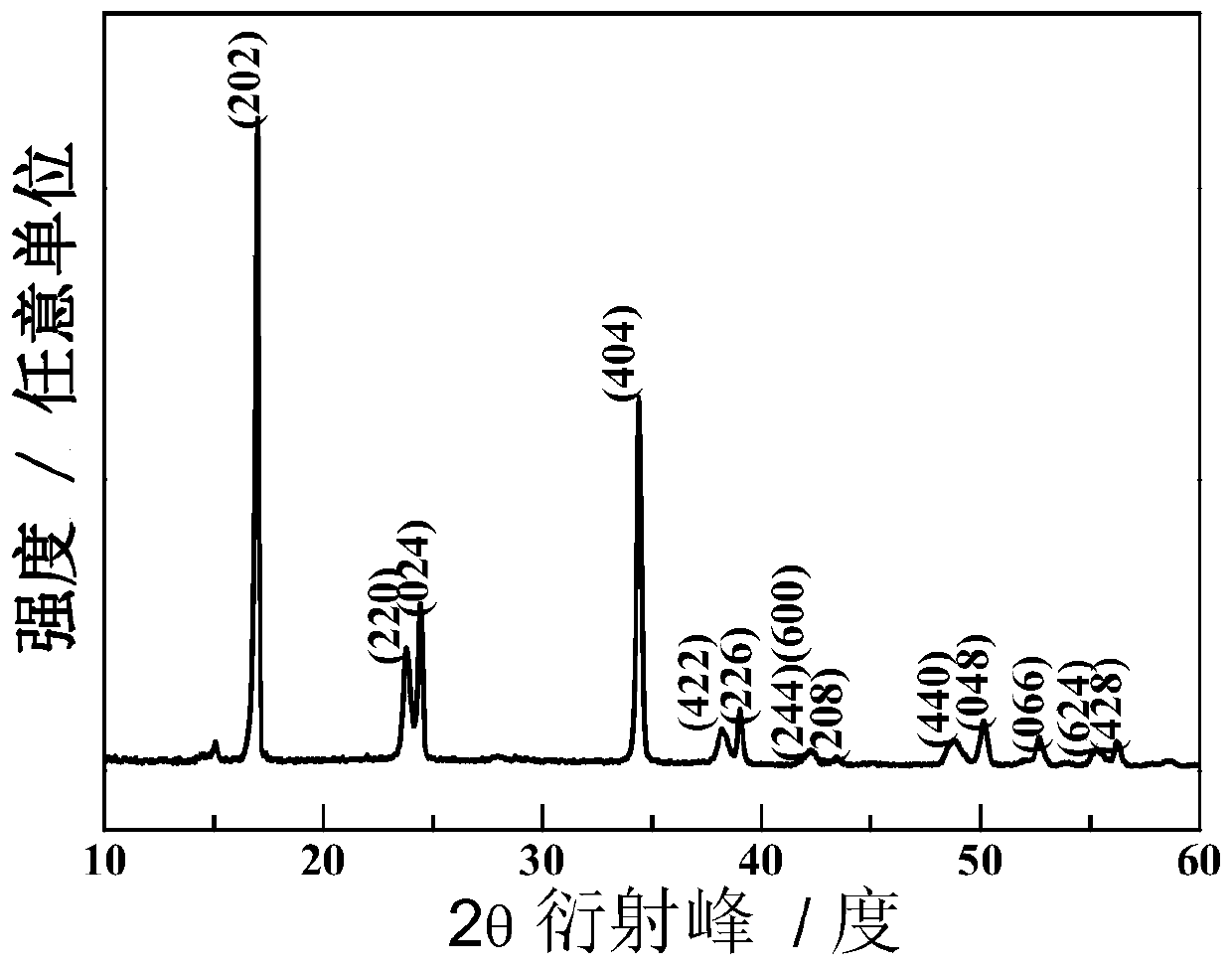

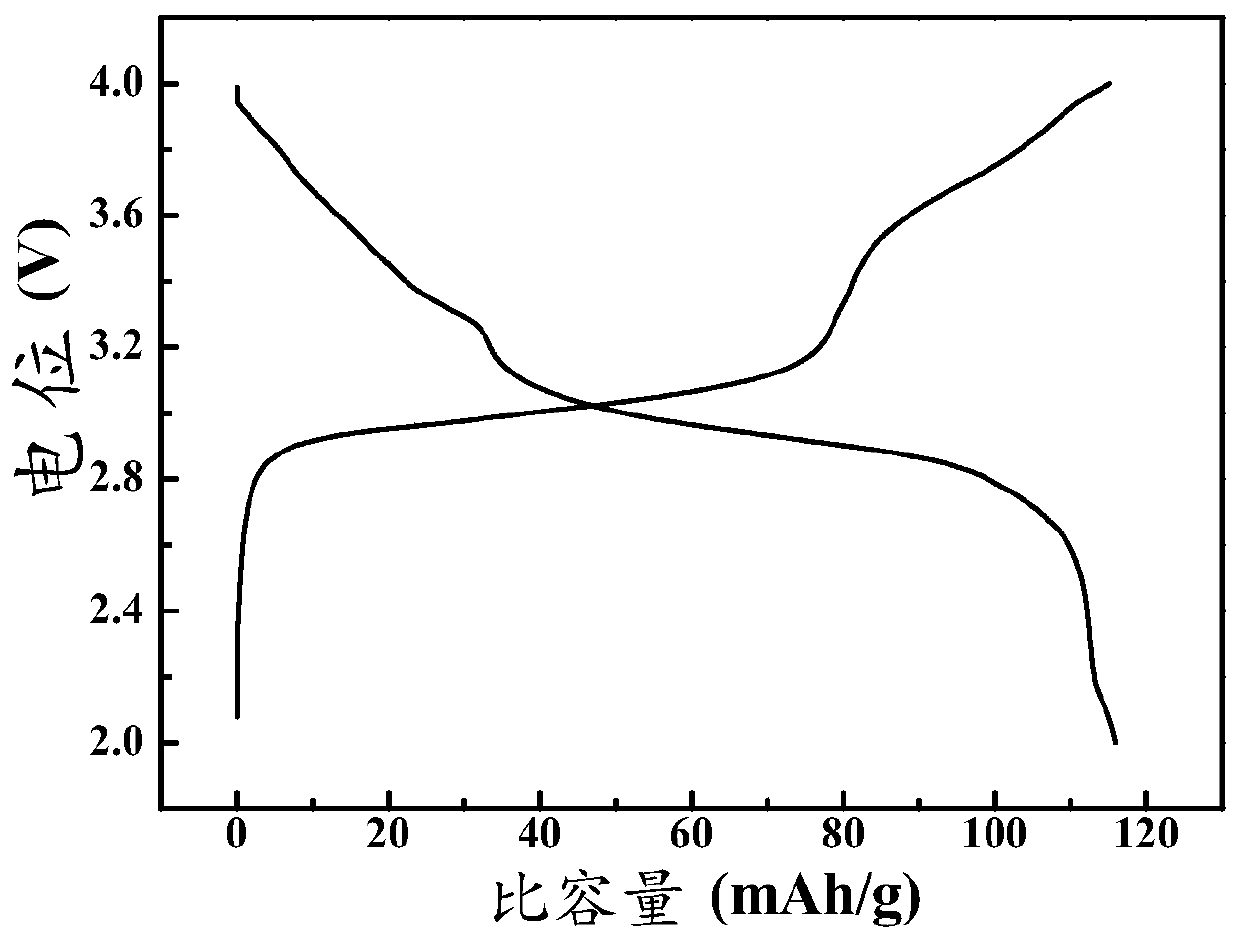

[0032] figure 1 The XRD of the Prussian blue material prepared in this embodiment was analyzed as a monoclinic phase. figure 2 The SEM photo of the Prussian blue material prepared in this example shows that the particles exhibit a stepped cubic hierarchical structure, and the particle size is 3 to 5 microns. The Prussian blue material prepared in this example is used as the positive electrode, sodium metal is used as the negative electrode, glass fib...

Embodiment 2

[0044] Dissolve sodium ferrocyanide decahydrate in 50 ml of deionized water, stir evenly to obtain a solution I with a concentration of 0.01 mol / L; dissolve ferrous chloride, ascorbic acid, and sodium citrate in 50 ml of deionized water to obtain Solution II with concentrations of 0.0105 mol / L, 0.005 mol / L, and 0.1 mol / L; solution I and solution II were added to 100 ml of deionized water at the same time, co-precipitation reaction at 20 ℃, and then washing, Na is obtained after centrifugal separation and vacuum drying x FeFe(CN) 6 . After electrochemical test, when the current density is 15mA / g, the initial discharge capacity of the product can reach 115mAh / g.

Embodiment 3

[0046] Dissolve sodium ferrocyanide decahydrate in 50 ml of deionized water, stir evenly to obtain a solution I with a concentration of 0.1 mol / L; dissolve ferrous nitrate, ascorbic acid, and sodium citrate in 50 ml of deionized water to obtain the concentration 0.115mol / L, 0.1mol / L, and 5mol / L solution II; add solution I and solution II to 100ml of deionized water at the same time, after co-precipitation reaction at 20℃, then washing and centrifugal separation , Get Na after vacuum drying x FeFe(CN) 6 . After electrochemical testing, when the current density is 15mA / g, the initial discharge capacity of the product can reach 118mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Initial discharge capacity | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com