A resource disposal method for low-concentration heavy metal ion wastewater

A low-concentration heavy metal and heavy metal ion technology, which is applied in chemical instruments and methods, water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problems of difficult engineering promotion and application, upgrading of reaction equipment materials, and reduction of power utilization efficiency, etc. problems, to achieve the effect of alleviating the deteriorating environment of water resources, reducing the expenditure of water resource costs, and reducing the payment of sewage charges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

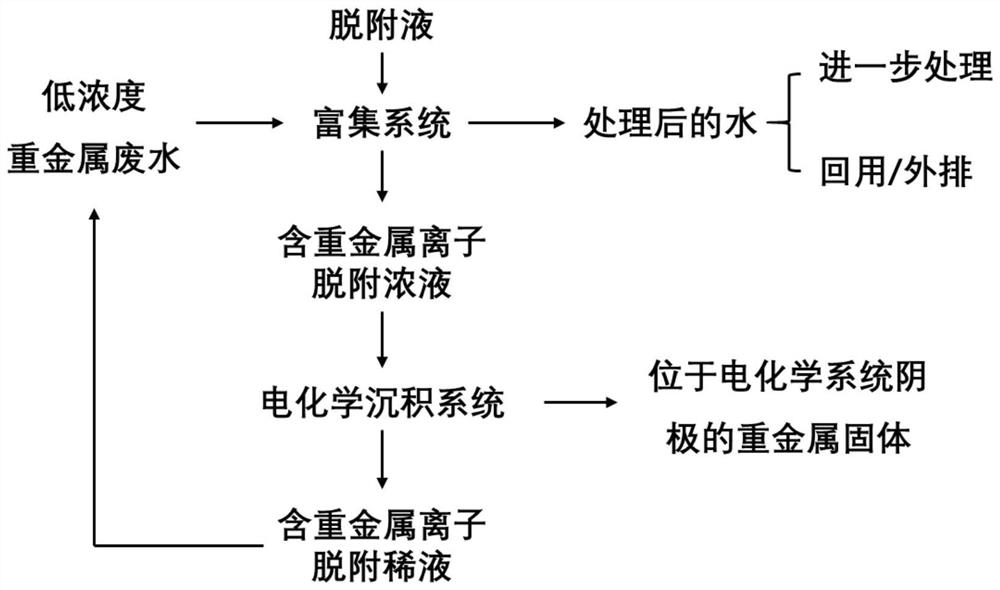

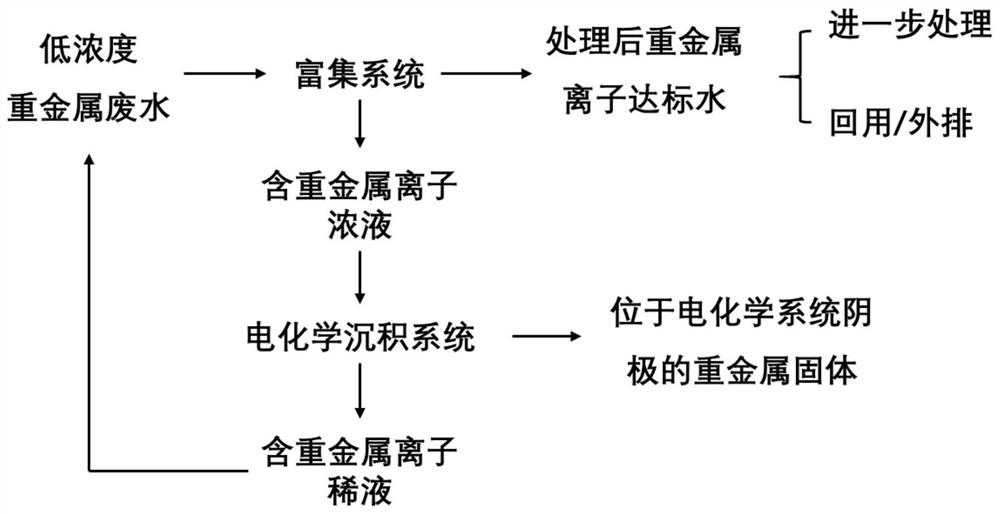

[0036] Example 1: Combining figure 1 and figure 2 ; A resource disposal method for low-concentration heavy metal ion wastewater, characterized in that, comprising the following steps,

[0037]The low-concentration heavy metal ion wastewater to be treated enters the enrichment system for treatment. According to the different treatment methods selected by the enrichment system, the heavy metal ions in the water can be trapped inside the treatment system or exist in the concentrated water of the system effluent; enrichment The heavy metal ion standard water produced by the system can be discharged, reused or entered into the next treatment process;

[0038] When the heavy metal ions in the wastewater are trapped inside the treatment system, it is necessary to use the desorption liquid to desorb the system when the enrichment system is operating to a saturated state, so that the adsorbed heavy metal ions are desorbed in the desorption liquid. Form a desorption dope containing h...

Embodiment 2

[0043] Embodiment two: as a further improved scheme or a parallel scheme, the enrichment system selects the adsorbent method to form an adsorbent-electrodeposition combined process, and the copper-containing wastewater (ρ(Cu 2+ )=400mg / L, pH=5) for recycling.

[0044] Polypyrrole-titanium dioxide composite adsorbent (PPy-TiO 2 Adsorbent, self-made, Langmiur, 2018, 34:10187) to treat copper-containing wastewater, the dosage of the adsorbent is 2g / L, and the adsorption effect is the best at 25°C for 2h. 0.1M of H 2 SO 4 The solution was passed through the saturated PPy-TiO 2 Desorbed in the adsorbent, Cu can be obtained 2+ The desorption concentrate with a mass concentration of 8080 mg / L and a pH of 1. Conduct electrodeposition test on the desorption concentrate to recover copper, at a current density of 200A / m 2 , temperature 60°C, pH 1, plate spacing 15mm, electrolysis time 4h, for 500mL initial Cu 2+ The mass concentration is 8080mg / L for electrolysis, the copper recov...

Embodiment 3

[0045] Embodiment three: as a further improved scheme or a parallel scheme, the enrichment system selects the ion exchange resin method to form an ion exchange resin-electrodeposition combined process, and the copper-containing wastewater (ρ(Cu 2+ )=600mg / L, pH=2) for recycling.

[0046] Using iminodiacetic acid type chelating resin (D402 chelating resin, purchased) to treat copper-containing wastewater, the removal rate is 4 when the pH is 4, the dynamic adsorption effect is the best when the maximum flow rate is 6BV / h, and the breakthrough time is 213.1 min. The mass fraction of 10% H 2 SO 4 The solution is passed into the ion exchange column that has been penetrated for desorption, and Cu can be obtained 2+ The regeneration solution with a mass concentration of 10380 mg / L and a pH of 0.8. Electrodeposition test was carried out on the regeneration solution of the resin to recover copper. Under the conditions of current density of 200A / m2, temperature of 60°C, pH of 0.8, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com