Wastewater treatment method of fluorine-containing aniline compounds

A technology for treating fluorine-containing aniline and wastewater, which is applied in the fields of special compound water treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of few treatment technology reports and difficult treatment, and achieve easy realization, thorough treatment, Obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

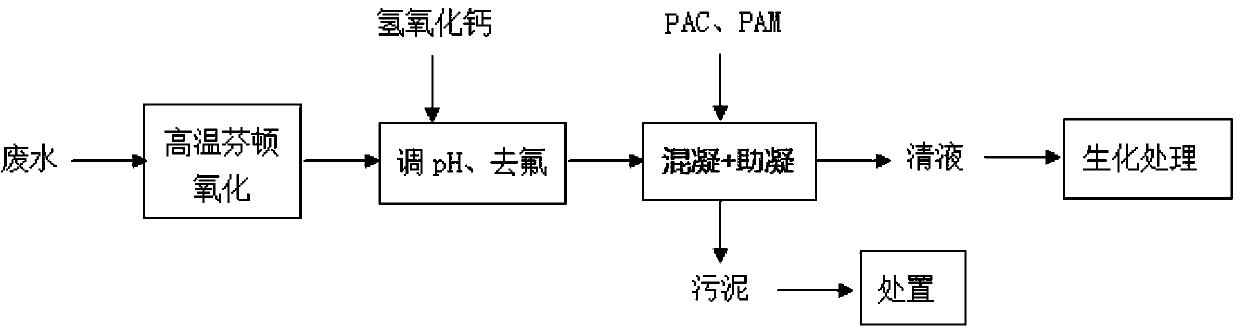

[0043] Wastewater treatment route of the present invention such as figure 1 As shown, the specific steps are as follows:

[0044] 1) High temperature Fenton oxidation

[0045] Use dilute hydrochloric acid to adjust the pH of wastewater containing 2,6-difluoroaniline to 2, add ferrous sulfate heptahydrate to the wastewater at a ratio of 0.2%, stir to dissolve, keep the temperature at 70°C, and then drip while stirring Add hydrogen peroxide, the ratio of hydrogen peroxide consumption to COD is 7:1, and the entire oxidation reaction time is 3 hours.

[0046] 2) Dosing calcium hydroxide to remove fluoride

[0047] Add calcium hydroxide solution with a concentration of 20% to the oxidized wastewater, and the added quality is 4.5% of the wastewater volume. At this time, the pH of the wastewater is 9.6, and the calcium hydroxide is slightly excessive.

[0048] 3) Coagulation + coagulation aid

[0049] Add a PAC aqueous solution with a concentration of 10% to the wastewater. The d...

Embodiment 2

[0053] 1) High temperature Fenton oxidation

[0054] Use dilute hydrochloric acid to adjust the pH of wastewater containing 2,6-difluoroaniline to 3.2, add ferrous sulfate heptahydrate to the wastewater at a ratio of 0.3%, stir to dissolve, keep the temperature at 60°C, and then drip while stirring Add hydrogen peroxide, the ratio of hydrogen peroxide consumption to COD is 10:1, and the entire oxidation reaction time is 4.5h.

[0055] 2) Dosing calcium oxide to remove fluoride

[0056] Add a calcium oxide solution with a concentration of 30% to the oxidized wastewater, and the quality of the addition is 2.35% of the wastewater volume, and at the same time drop liquid alkali to adjust the pH of the wastewater to 8.7.

[0057] 3) Coagulation + coagulation aid

[0058] Add 10% polyferric sulfate (PFS) solution to the wastewater, the dosage of PFS solution is 3.5% of the wastewater volume, stir and mix well, let it stand for 6 minutes; then add dropwise the PAM aqueous solution ...

Embodiment 3

[0062] 1) High temperature Fenton oxidation

[0063] Use dilute hydrochloric acid to adjust the pH of wastewater containing 2,4-difluoroaniline to 4, add ferrous sulfate heptahydrate to the wastewater at a ratio of 0.43%, stir to dissolve, keep the temperature at 50°C, and then drip while stirring Add hydrogen peroxide, the ratio of hydrogen peroxide consumption to COD is 16:1, and the entire oxidation reaction time is 4 hours.

[0064] 2) Dosing calcium chloride to remove fluoride

[0065] Add a calcium chloride solution with a concentration of 40% to the oxidized wastewater, and the added quality is 1.8% of the wastewater volume, and adjust the pH of the wastewater to 8.3 with liquid alkali.

[0066] 3) Coagulation + coagulation aid

[0067] Add 10% PAC solution to the wastewater, the dosage of PAC solution is 3% of the wastewater volume, stir and mix well, let it stand for 5 minutes; then add dropwise PAM aqueous solution with a mass fraction of 1%, the dosage is about 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com