Ceramic fiber wood plastic and manufacturing method thereof

A technology of ceramic fiber and manufacturing method, applied in the field of ceramic fiber wood plastic and its manufacturing, can solve the problems affecting the safety and life of wood plastic products, fire performance, poor sound insulation performance, and defects in the use performance of wood plastic products, etc. Anti-radiation effect, good thermal insulation performance, improving safety and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

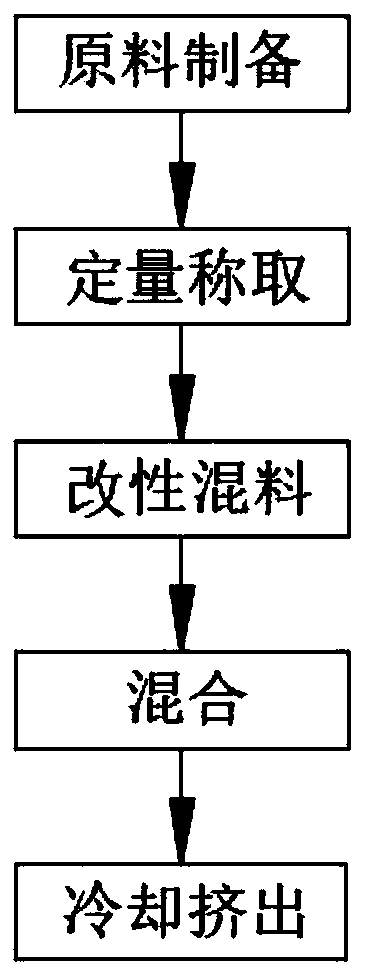

Method used

Image

Examples

Embodiment 1

[0028] A kind of ceramic fiber wood plastic, the wood plastic component includes 50 parts of plant fiber, 17 parts of ceramic fiber, 12 parts of porous ceramic particles, 16 parts of thermoplastic resin, 6 parts of glass fiber, 4 parts of flame retardant, surface 5 parts of modifier, 3 parts of stabilizer, 3 parts of foaming agent, 2 parts of foam regulator, 1 part of coupling agent.

[0029] Further, the diameter of the ceramic fibers is between 0.1-10 μm, and the ceramic fibers with a diameter of no more than 4 μm account for 75-90% of the total amount of ceramic fibers.

[0030] Further, the diameter of the porous ceramic particles is between 1.5-3mm.

[0031] Further, the plant fiber is one or more of wood flour, rice husk, crop straw, and waste paper.

[0032] Further, the diameter of the plant fibers is between 1-4 mm, and the plant fibers with a diameter of no more than 2.5 mm account for 65-75% of the total plant fibers.

[0033] Further, the thermoplastic resin is a...

Embodiment 2

[0046] A kind of ceramic fiber wood plastic, the wood plastic component includes 58 parts of plant fiber, 15 parts of ceramic fiber, 10 parts of porous ceramic particles, 18 parts of thermoplastic resin, 5 parts of glass fiber, 5 parts of flame retardant, surface 4 parts of modifier, 4 parts of stabilizer, 5 parts of foaming agent, 3 parts of foam regulator, 1 part of coupling agent.

[0047] Further, the diameter of the ceramic fibers is between 0.1-10 μm, and the ceramic fibers with a diameter of no more than 4 μm account for 75-90% of the total amount of ceramic fibers.

[0048] Further, the diameter of the porous ceramic particles is between 1.5-3mm.

[0049] Further, the plant fiber is one or more of wood flour, rice husk, crop straw, and waste paper.

[0050] Further, the diameter of the plant fibers is between 1-4 mm, and the plant fibers with a diameter of no more than 2.5 mm account for 65-75% of the total plant fibers.

[0051] Further, the thermoplastic resin is a...

Embodiment 3

[0064] A kind of ceramic fiber wood plastic, the wood plastic component includes 40 parts of plant fiber, 20 parts of ceramic fiber, 15 parts of porous ceramic particles, 15 parts of thermoplastic resin, 7 parts of glass fiber, 3 parts of flame retardant, surface 7 parts of modifier, 2 parts of stabilizer, 2 parts of foaming agent, 1 part of foam regulator, and 1 part of coupling agent.

[0065] Further, the diameter of the ceramic fibers is between 0.1-10 μm, and the ceramic fibers with a diameter of no more than 4 μm account for 75-90% of the total amount of ceramic fibers.

[0066] Further, the diameter of the porous ceramic particles is between 1.5-3mm.

[0067] Further, the plant fiber is one or more of wood flour, rice husk, crop straw, and waste paper.

[0068] Further, the diameter of the plant fibers is between 1-4 mm, and the plant fibers with a diameter of no more than 2.5 mm account for 65-75% of the total plant fibers.

[0069] Further, the thermoplastic resin i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com