SMA modified asphalt concrete bridge deck pavement based on improved coarse aggregate pebble interface

A technology of modified asphalt and bridge deck pavement, which is applied in the direction of surface layering devices, bridges, bridge parts, etc., and can solve problems such as poor adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

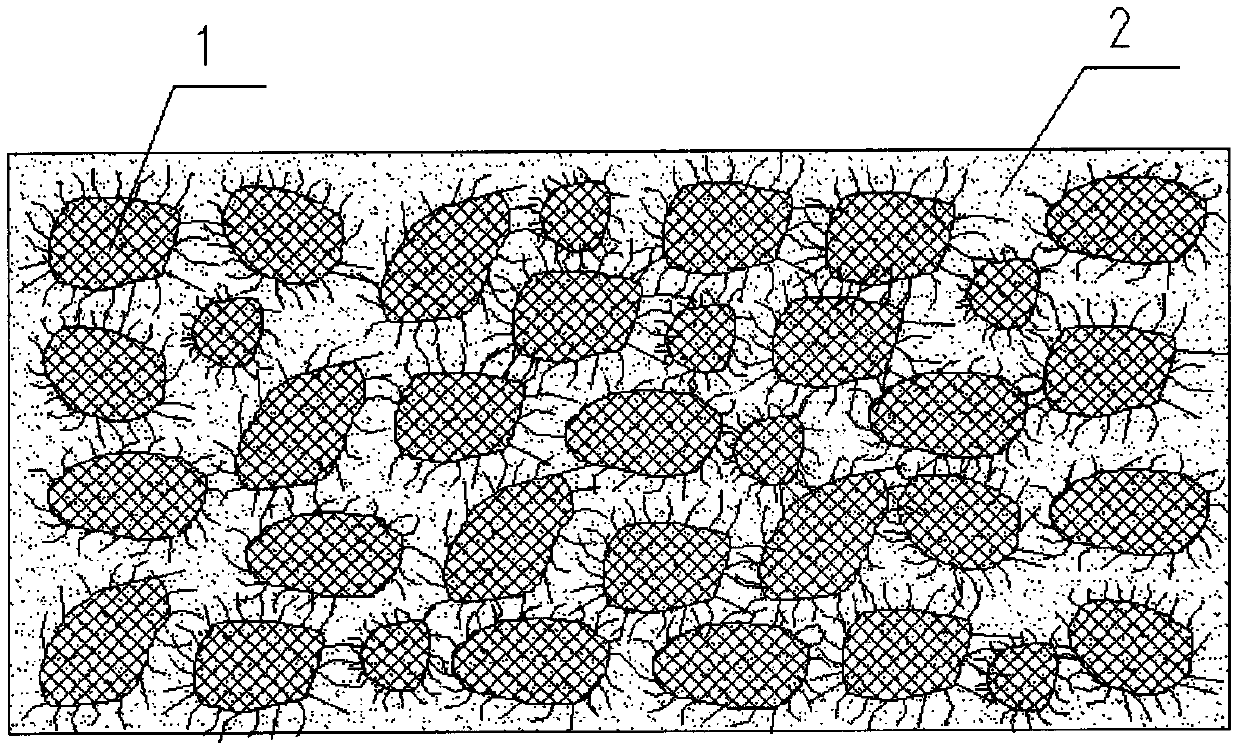

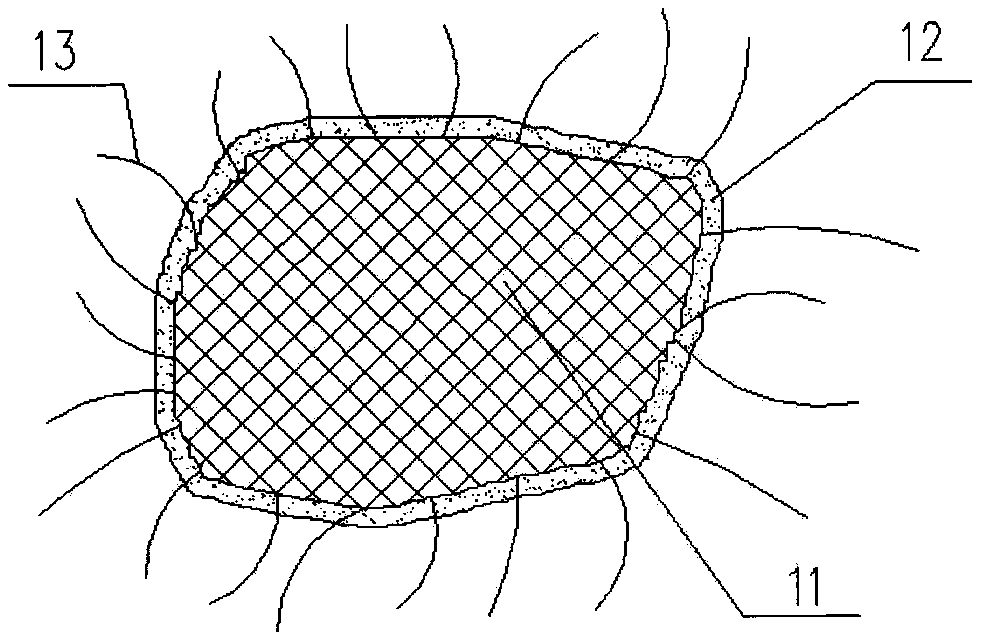

[0071] A kind of SMA modified asphalt concrete bridge deck pavement based on improved coarse aggregate stone interface of the present invention, comprises improved coarse aggregate stone 1 and modified asphalt mastic 2, and described improved coarse aggregate stone 1 is made of Coarse aggregate stone inner core 11, polymer cement mortar outer coating layer 12 and adhesive microfiber wool layer 13, polymer cement mortar outer coating layer 12 wraps coarse aggregate stone inner core 11, adhesive microfiber wool layer 13 is glued Anchored on the polymer cement mortar outer coating layer 12, an improved coarse aggregate stone 1 is formed; the modified asphalt mastic 2 is mixed with SBS modified asphalt, a small amount of fine aggregate, mineral powder, fiber stabilizer, On the basis of the mixture composed of antioxidant and anti-stripping agent, graphene sponge, carbon fiber filament, polymer modifier and rubber modifier are added to form modified asphalt mastic 2, and heating mod...

Embodiment 2

[0073] A preparation method of the improved coarse aggregate stone 1 based on the SMA modified asphalt concrete bridge deck pavement of the improved coarse aggregate stone interface comprises the following steps:

[0074] The first step: wash and dry the coarse aggregate stone inner core 11, and use the method of spraying and immersing the polymer emulsion to form a thin layer of polymer emulsion coating on the surface of the coarse aggregate stone inner core 11;

[0075] Step 2: The polymer cement mortar coating layer 12 is mainly composed of water-based polymer latex, ordinary Portland cement, quartz sand and silica fume, and is prepared by adding various modification additives. Mixing mortar, its weight ratio is: cement 15-25%, polymer emulsion 8-12%, quartz sand 40-60%, silicon powder 5-10%, carbon nanotube airgel particles 0.5-1%, graphite 0.05-0.1% olefin, 0.5-1% polycarboxylate high-efficiency water reducer, 0.03-0.12% coagulant, etc. Stir evenly, then put 10kg of pre-m...

Embodiment 3

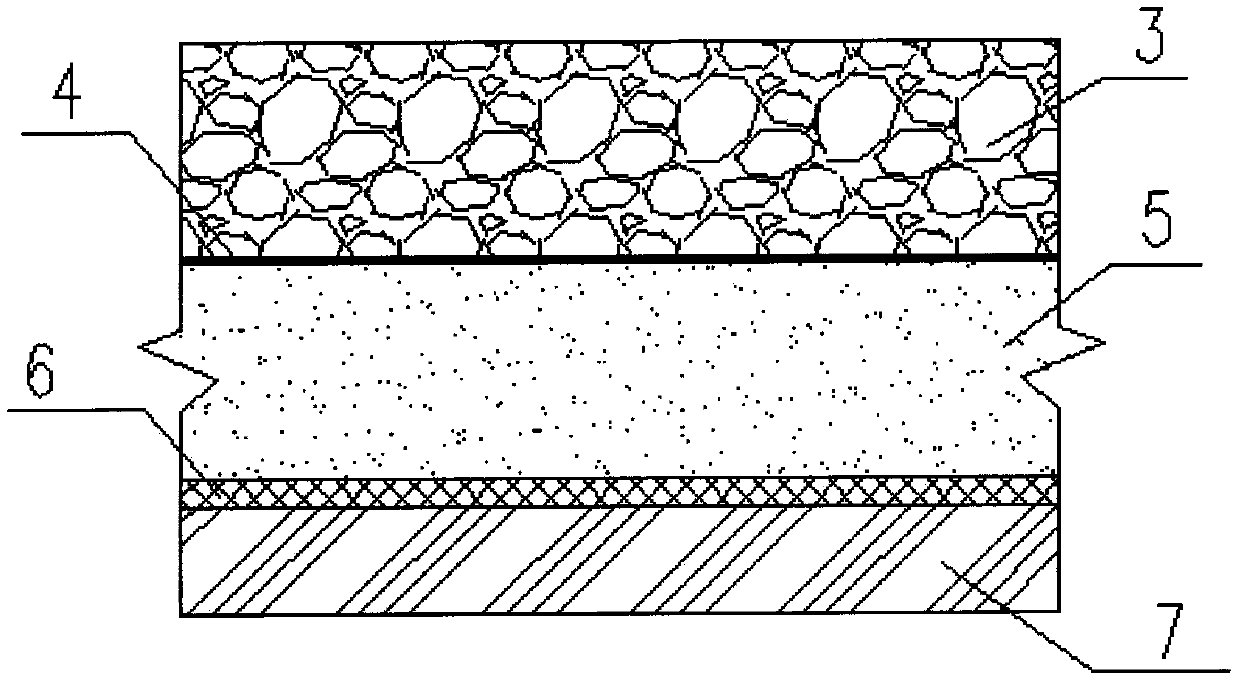

[0079] A preparation method for SMA-modified asphalt concrete bridge deck pavement based on the improved phase aggregate stone interface comprises the following steps:

[0080] The first step: deploy modified asphalt, according to the weight ratio: 100 parts of base asphalt; 6-8 parts of SBS modifier; 4-6 parts of styrene-butadiene rubber powder, 3-5 parts of EVA polymer modifier; carbon fiber 4-6 parts of silk; 1-2 parts of graphene sponge particles;

[0081] The second step: deploy modified asphalt mastic 2, according to the weight ratio: 100 parts of modified asphalt; 110-160 parts of mineral powder; 5-10 parts of fiber stabilizer; 2-4 parts of anti-stripping agent; 1-2 parts of oxygen agent; castor oil: 1-2 parts;

[0082] The third step: Prepare SMA asphalt concrete, according to the weight ratio: the amount of modified coarse aggregate stone 1 is 70-80%; the amount of modified asphalt mastic 2 is 20-30%;

[0083] Step 4: After heating the modified asphalt mastic 2, fee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com