Preparation method of flexible fabric supercapacitor electrode material taking graphene/polypyrrole as active substance

A supercapacitor and active material technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of poor cycle performance of supercapacitors and attenuation of capacitance performance, so as to improve space utilization and reduce interface Impedance, the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

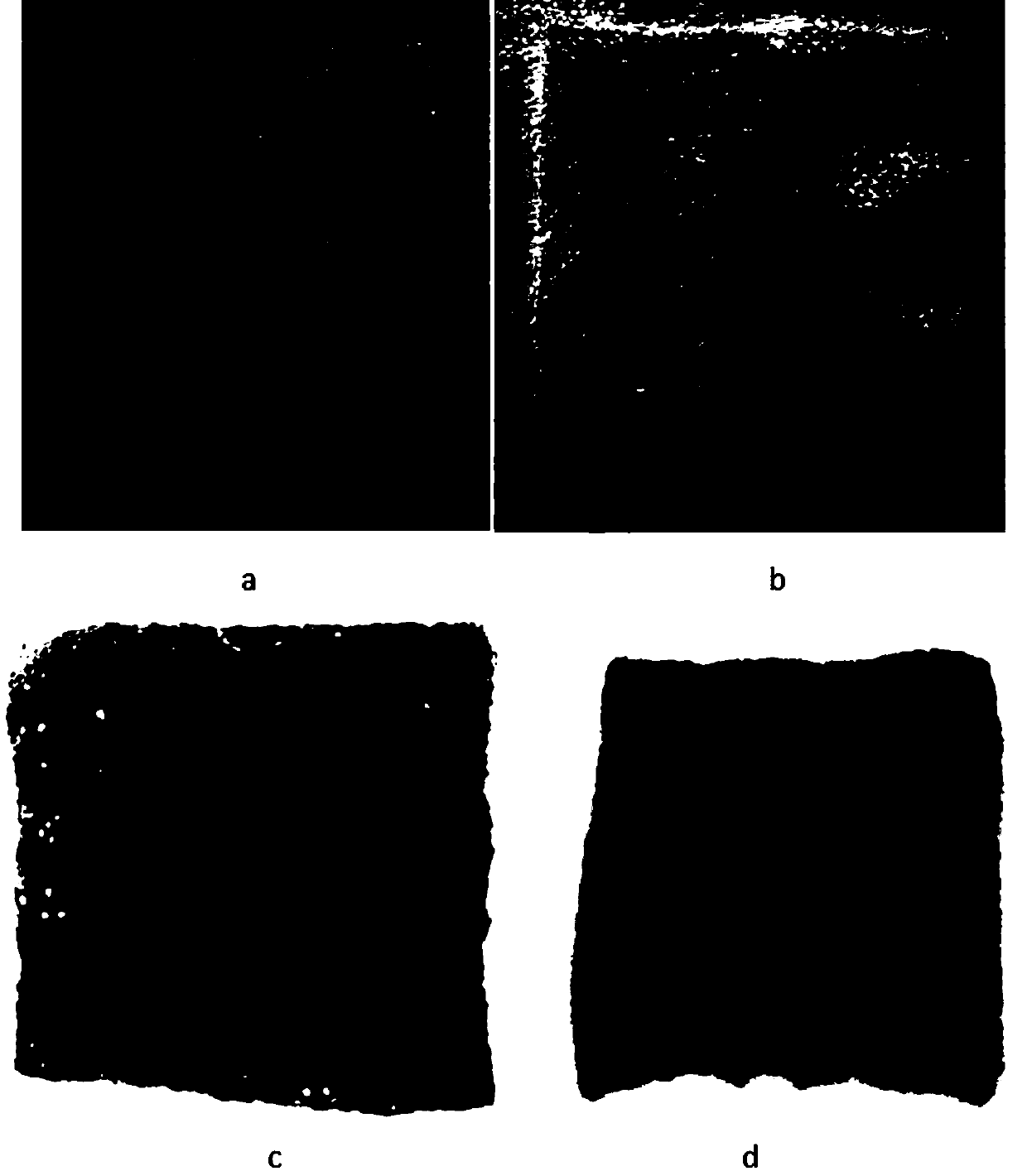

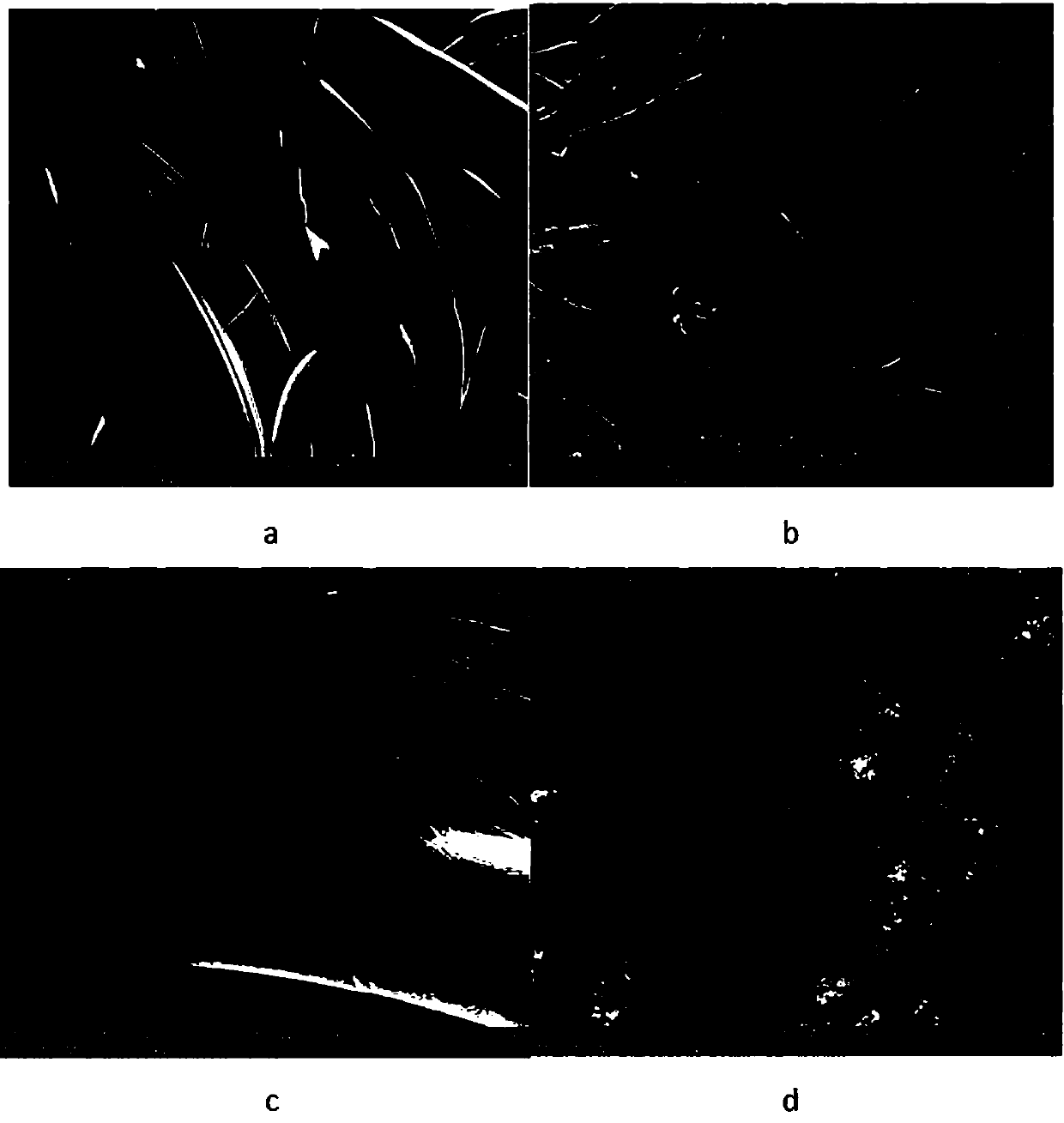

Image

Examples

Embodiment 1

[0028] The preparation method of the flexible fabric supercapacitor electrode material using graphene / polypyrrole as the active material of the present embodiment, the steps are as follows:

[0029] (1) Prepare a glutaraldehyde aqueous solution with a concentration of 0.9%, adjust its pH value to 4.5 with hydrochloric acid, and make a carboxymethyl chitosan / viscose blended nonwoven with a carboxymethyl chitosan fiber content of 30% The cloth (2×4cm) was soaked in the glutaraldehyde aqueous solution for 5 minutes and then taken out, placed in an oven at 45° C. for 1.5 hours to cross-link and dry to obtain a cross-linked carboxymethyl chitosan / viscose blended non-woven fabric.

[0030] (2) Immerse the cross-linked carboxymethyl chitosan / viscose blended non-woven fabric into the graphene aqueous dispersion with a concentration of 1mg / ml, take it out after soaking for 2 minutes, and dry it in an oven at 50°C After 3 hours, the graphene / non-woven composite material was obtained aft...

Embodiment 2

[0035] The preparation method of the flexible fabric supercapacitor electrode material using graphene / polypyrrole as the active material of the present embodiment, the steps are as follows:

[0036] (1) Prepare a succinic dialdehyde aqueous solution with a concentration of 0.3%, adjust its pH value to 5 with hydrochloric acid, and make a carboxymethyl chitosan / viscose blended nonwoven with a carboxymethyl chitosan fiber content of 50% The cloth (2×4 cm) was immersed in the succinic dialdehyde aqueous solution for 8 minutes and then taken out, placed in an oven for cross-linking and drying at 60° C. for 1.0 hour to obtain a cross-linked carboxymethyl chitosan / viscose blended non-woven fabric.

[0037] (2) Immerse the cross-linked carboxymethyl chitosan / viscose blended non-woven fabric into the graphene aqueous dispersion with a concentration of 2mg / ml, take it out after soaking for 30 minutes, and dry it in an oven at 80°C After 1 hour, the graphene / non-woven composite material...

Embodiment 3

[0042] The preparation method of the flexible fabric supercapacitor electrode material using graphene / polypyrrole as the active material of the present embodiment, the steps are as follows:

[0043] (1) Prepare an aqueous solution of adipaldehyde with a concentration of 0.45%, adjust its pH value to 4.5 with hydrochloric acid, and prepare a carboxymethyl chitosan / viscose blended nonwoven with a carboxymethyl chitosan fiber content of 50% The cloth (2×4cm) was soaked in the adialdehyde aqueous solution for 5 minutes and then taken out, placed in an oven at 50° C. for cross-linking and drying for 1.2 hours to obtain a cross-linked carboxymethyl chitosan / viscose blended non-woven fabric.

[0044] (2) Immerse the cross-linked carboxymethyl chitosan / viscose blended non-woven fabric into the graphene aqueous dispersion with a concentration of 1.5mg / ml, take it out after soaking for 10 minutes, and place it in an oven at 60°C After drying for 2.5 hours, the graphene / non-woven fabric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Area specific capacitance | aaaaa | aaaaa |

| Area specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com