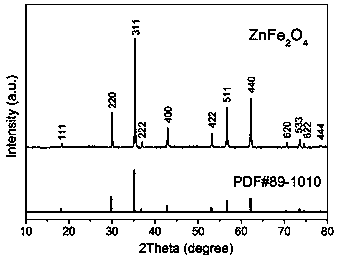

Preparation method of ZnFe2O4 nanocube for a lithium ion battery negative electrode material

A nano-cube, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of unstable structure, complex preparation process, short cycle life, etc., and achieve stable structure, simple preparation process and long cycle. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

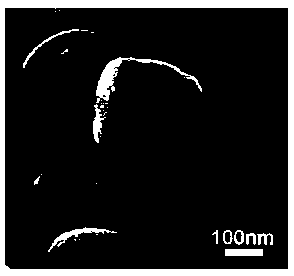

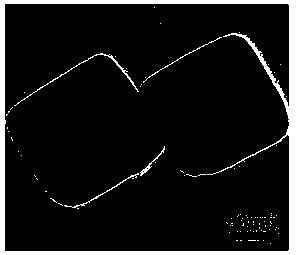

[0029] As a specific embodiment, 2 mmol of zinc nitrate hexahydrate and 4 mmol of ferrous sulfate heptahydrate were added to a mixed solution of 33 mL of water and 2 mL of ethanolamine, and stirred to form a uniform suspension. Then the suspension was transferred to a reaction kettle with a polytetrafluoroethylene liner, and reacted at a constant temperature of 170° C. for 10 h. After the reaction was complete, the precipitate was collected by filtration, washed three times with deionized water and absolute ethanol, and vacuum-dried at 80° C. to obtain a brown-yellow solid powder product.

[0030] The lithium-ion battery negative electrode material prepared by the present invention is assembled into a button battery, and the test method is as follows: ZnFe 2 o 4 Mix the powder, SuperP conductive carbon, and polyvinylidene fluoride binder at a mass ratio of 70:20:10, add an appropriate amount of N-methylpyrrolidone solvent and stir evenly, apply it on a copper foil, and dry it...

Embodiment 2

[0038] Add 2mmol of zinc nitrate hexahydrate and 4mmol of ferrous sulfate heptahydrate into a mixed solution of 34.5mL of water and 0.5mL of ethanolamine, and stir to form a uniform suspension. Then the suspension was transferred to a reaction kettle with a polytetrafluoroethylene liner, and reacted at a constant temperature of 170° C. for 10 h. After the reaction was complete, the precipitate was collected by filtration, washed three times with deionized water and absolute ethanol, and vacuum-dried at 80° C. to obtain a brown-yellow solid powder product.

Embodiment 3

[0040] Add 2mmol of zinc nitrate hexahydrate and 4mmol of ferrous sulfate heptahydrate into a mixed solution of 34mL of water and 1mL of ethanolamine, and stir to form a uniform suspension. Then the suspension was transferred to a reaction kettle with a polytetrafluoroethylene liner, and reacted at a constant temperature of 180°C for 8 hours. After the reaction was complete, the precipitate was collected by filtration, washed three times with deionized water and absolute ethanol, and vacuum-dried at 80° C. to obtain a brown-yellow solid powder product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Capacity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com