Application method of water-soluble inorganic salt in drug lubrication

A water-soluble inorganic salt, application method technology, applied in the direction of pharmaceutical formulations, inorganic non-active ingredients, medical preparations containing active ingredients, etc., can solve the skin irritation of external drugs, affect the effect and taste of oral drugs, equipment corrosion To solve the problems of mechanical corrosion and taste/skin irritation, high potential economic benefits, and high drug content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

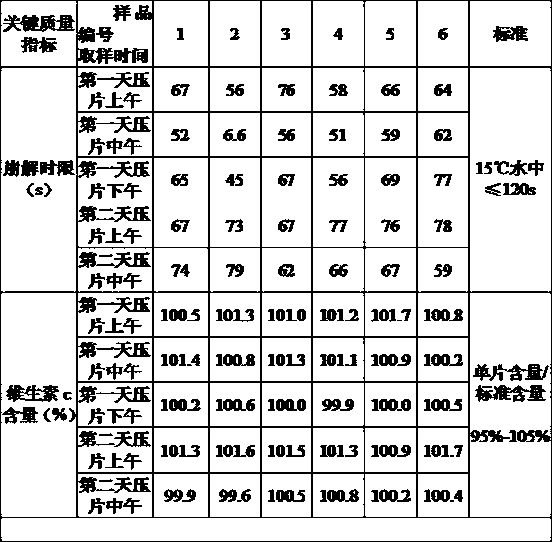

Examples

Embodiment 1

[0024] Ingredients: Weigh each raw material according to the prescription amount, as shown in Table 1, and set aside.

[0025] Table 1

[0026] prescription 2.5 million pieces of feed Vitamin C 1270.00kg Lactose (120 mesh) 355.00kg sodium bicarbonate 13000.00kg L-Tartrate 925.00kg aspartame 125.00kg Povidone K30 75.00kg polyethylene glycol 6000 203.50kg β-carotene 12.50kg Orange Juice Powder Flavor 7.50kg Sodium chloride 4.5kg D 4.5kg

[0027] Sodium chloride pretreatment: the sodium chloride is micronized by a jet mill, and its particle size is controlled to 8 μm, for later use.

[0028] Pretreatment of raw and auxiliary materials: crush the prescription amount of L-tartaric acid through an 80-mesh sieve, and pass through an 80-mesh sieve with sodium bicarbonate.

[0029] Preparation of wet granules: Add vitamin C, lactose, sodium bicarbonate, L-tartaric acid, aspartame, polyethylene ...

Embodiment 2

[0038] Ingredients: Weigh each raw material according to the prescription amount, as shown in Table 3, and set aside.

[0039] table 3

[0040] prescription 2.5 million pieces of feed Vitamin C 1270.00kg Lactose (120 mesh) 355.00kg sodium bicarbonate 13000.00kg L-Tartrate 925.00kg aspartame 125.00kg Povidone K30 75.00kg polyethylene glycol 6000 203.50kg β-carotene 12.50kg Orange Juice Powder Flavor 7.50kg potassium chloride 4.5kg D 4.5kg

[0041] Potassium chloride pretreatment: Micronize potassium chloride with a jet mill to control its particle size to 5 μm, and reserve it for later use.

[0042] Pretreatment of raw and auxiliary materials: crush the prescription amount of L-tartaric acid through an 80-mesh sieve, and pass through an 80-mesh sieve with sodium bicarbonate.

[0043] Preparation of wet granules: Add vitamin C, lactose, sodium bicarbonate, L-tartaric acid, aspartame, pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com