Novel anodic oxidation process of nickel-based thin film energy storage material

An energy storage material and anodic oxidation technology, which is applied in anodic oxidation, hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, etc., can solve problems such as insufficient electrolyte oxidation, poor controllability, and poor cycle stability , to achieve the effect of improving capacitance performance and electrochemical stability, short oxidation time and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

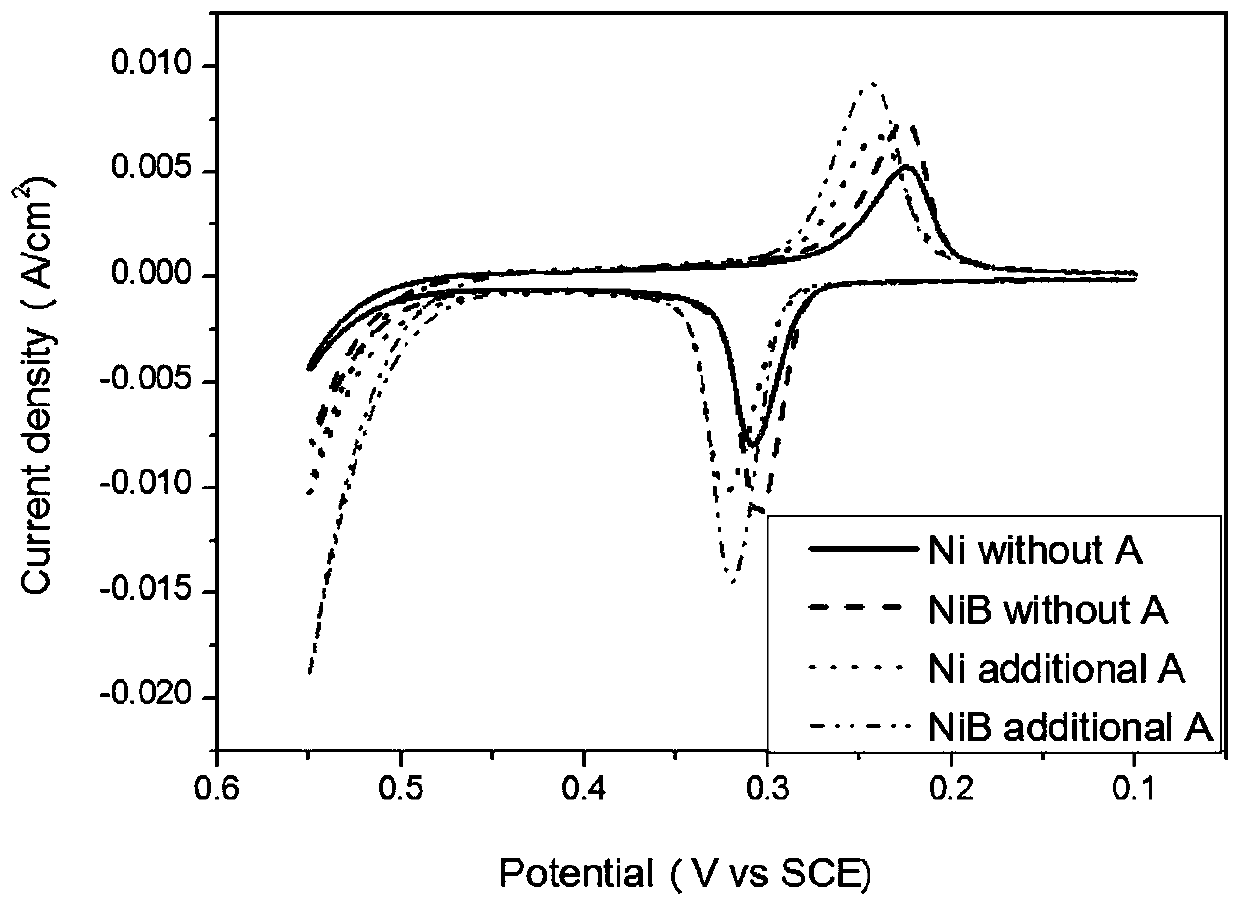

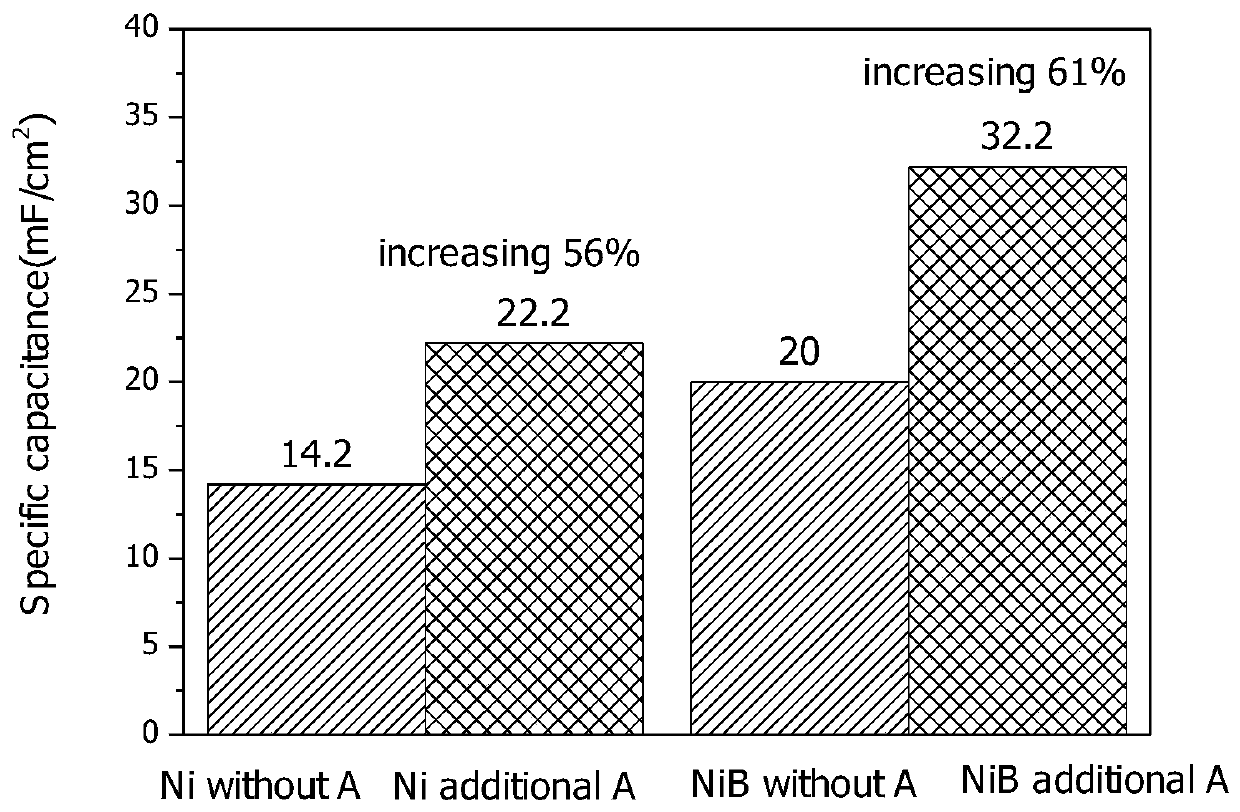

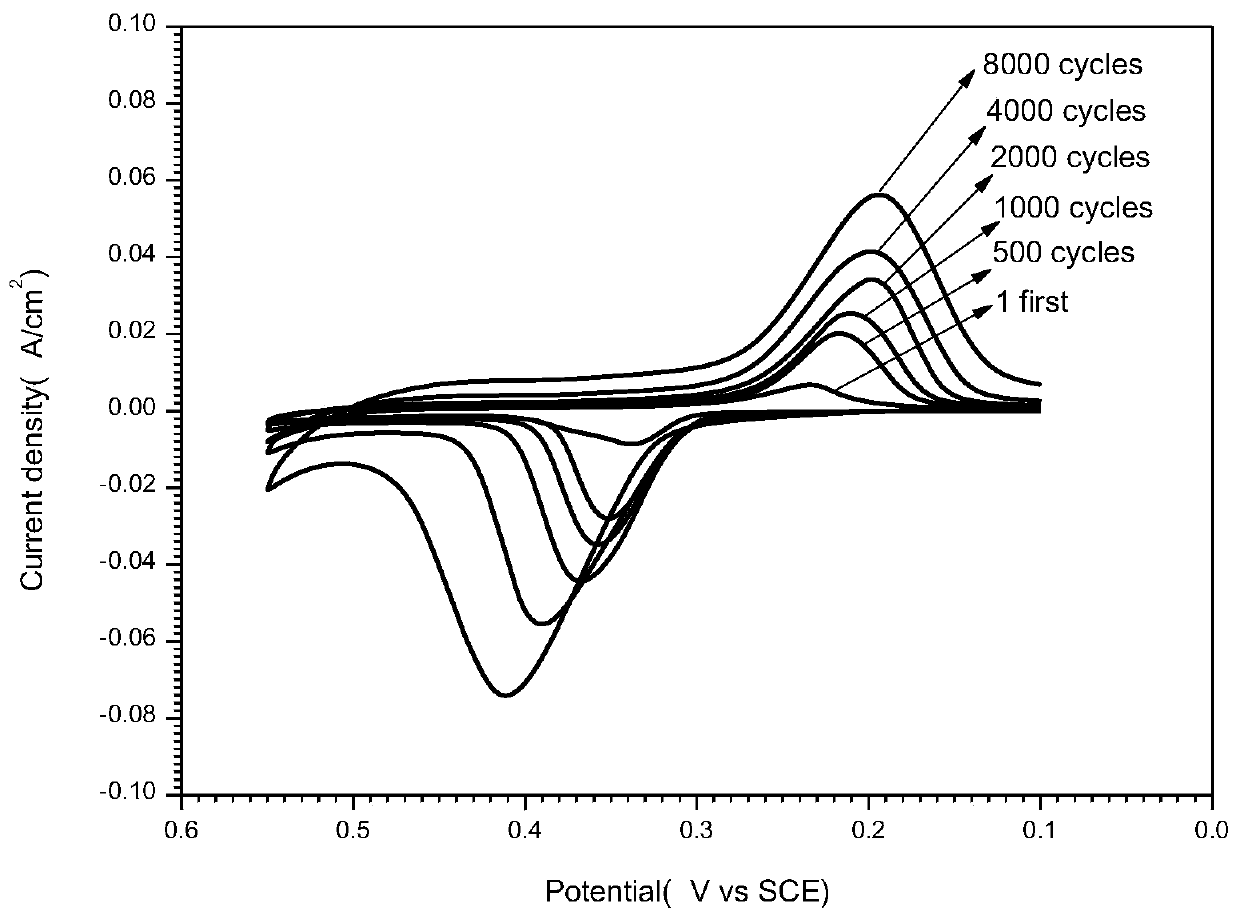

Embodiment 1

[0030] In this embodiment, a 0.5 mm thick thin copper sheet is used as a substrate, and 3 μm thick pure Ni and NiB coatings are deposited on its surface by electroless plating, and then oxidized under the preferred electrochemical oxidation process conditions of the present invention to prepare two A kind of NiO / NiOH supercapacitor electrode material, with the sample after electrochemical oxidation without adding pro-oxidant A as a comparative test, using a three-electrode system to study the capacitance performance and electrochemical stability of the oxidized nickel-based thin film energy storage electrode material, Test the cyclic voltammetry and galvanostatic charge and discharge in a typical supercapacitor electrolyte (in 2M KOH solution) to evaluate the capacitive performance and electrochemical stability of the electrode material, and use the three-electrode system to study the oxidized nickel-based thin film energy storage electrode The capacitive performance and electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com