A method and system for preparing an aluminum alloy surface wear-resistant ultra-fine micro-nano composite structure

A technology of micro-nano composite structure and aluminum alloy surface, which is applied in the direction of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., and can solve problems such as long cycle, complicated process, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The present invention provides a method and system for preparing a wear-resistant ultra-fine micro-nano composite structure on the surface of an aluminum alloy. The material technology scheme can realize the preparation of ultra-fine micro-nano structure on the surface of aluminum alloy, but the processing process is complicated, the efficiency is low, the preparation cycle is long, and it is not conducive to large-scale production, and the structure prepared by additive technology has low bonding strength with the substrate interface , The structural bearing capacity is weak and the wear resistance is poor. In order to more efficiently prepare wear-resistant super-fine micro-nano composite structures on the surface of aluminum alloys, the present invention provides an intelligent preparation method and system, which provides users with fully automatic or semi-automatic processing processes, and the adjustment is more accurate for different application environment requir...

Embodiment 1

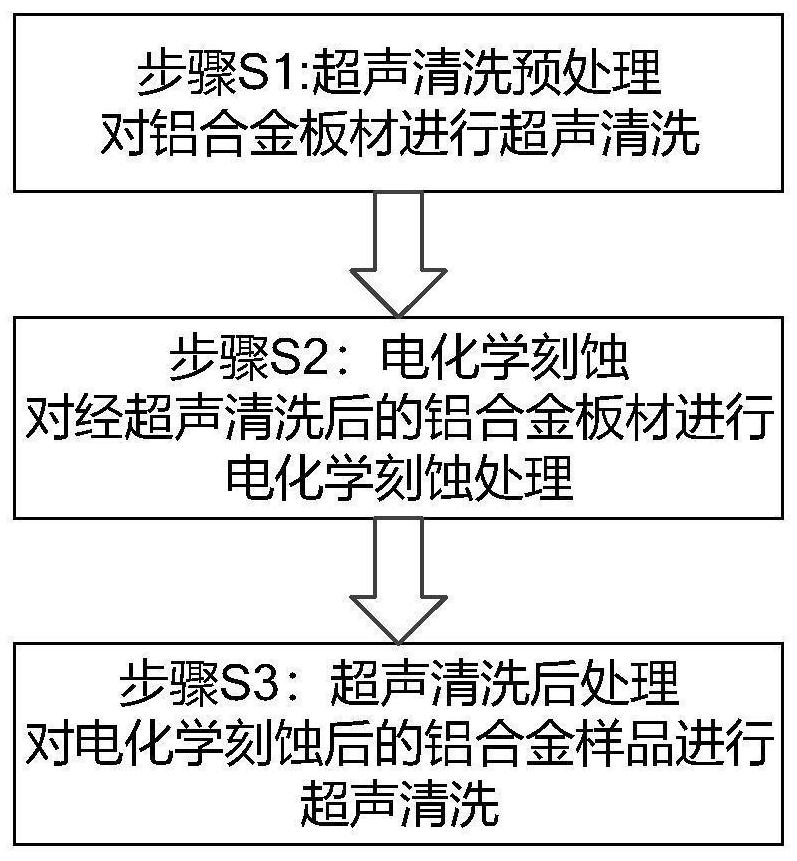

[0056] Embodiment one, see figure 1 :

[0057] Step S1. Ultrasonic cleaning pretreatment:

[0058] Ultrasonic cleaning is performed on aluminum alloy plates in a space with a closed pressure of 1.2-1.5Pa and an automatic constant temperature of 25°C, and automatically adjusts the frequency of ultrasonic cleaning according to the different cleaning objectives of the aluminum alloy surface to improve cleaning efficiency:

[0059] 1) First clean the oily organic matter on the surface of the aluminum alloy, such as mineral oil, synthetic oil, animal and vegetable oil, anti-rust oil and other oil stains and paints: select the cleaning target as oily ketone-soluble organic matter, put the aluminum alloy plate in acetone, and adjust it intelligently The ultrasonic cleaning frequency is 28kHz, and the ultrasonic cleaning is performed for 2 minutes;

[0060] 2) Clean surface lipid organic matter, such as wax, triglyceride, etc.: select the cleaning target as lipid alcohol-soluble org...

Embodiment 2

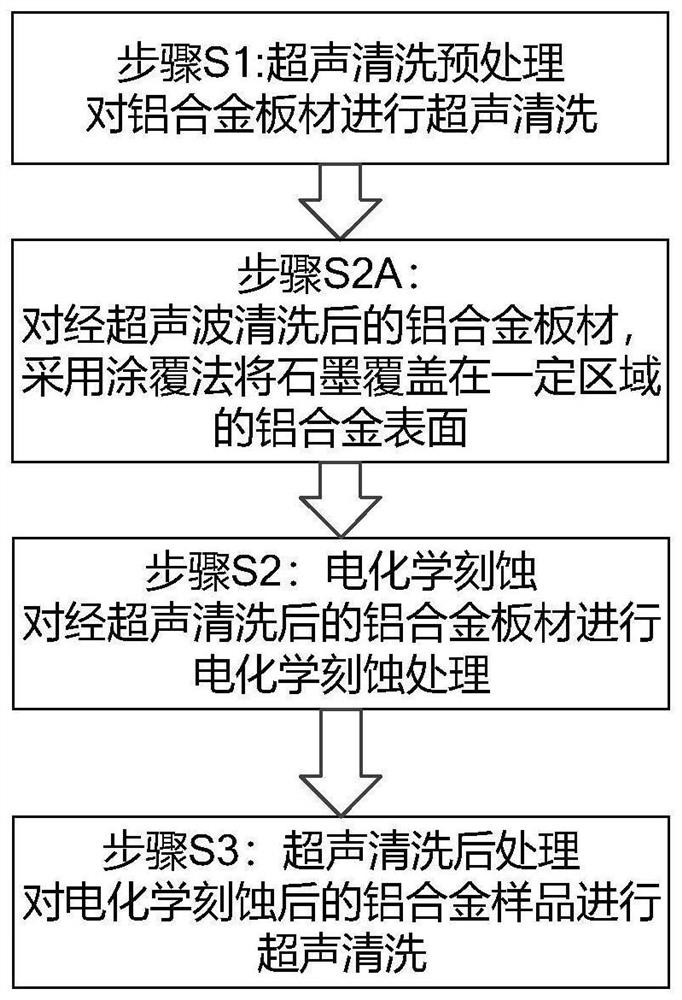

[0071] Embodiment two, see figure 2 :

[0072] Step S1. Ultrasonic cleaning pretreatment:

[0073] Ultrasonic cleaning is performed on aluminum alloy plates in a space with a closed pressure of 1.2-1.5Pa and an automatic constant temperature of 25°C. According to different cleaning objectives of the aluminum alloy surface, the frequency of ultrasonic cleaning is intelligently selected to improve cleaning efficiency:

[0074] 1) First clean the oily organic matter on the surface of the aluminum alloy: select the cleaning target as oily ketone-soluble organic matter, place the aluminum alloy plate in acetone, intelligently adjust the ultrasonic cleaning frequency to 28kHz, and perform ultrasonic cleaning for 2 minutes;

[0075] 2) Clean the surface oil: select the cleaning target as lipid alcohol-soluble organic matter, place the aluminum alloy sample after ultrasonic cleaning with acetone in absolute ethanol, intelligently adjust the ultrasonic cleaning frequency to 40kHz, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com