Alkyl glycoside sulfobetaine type ampholytic surfactant and preparation method thereof

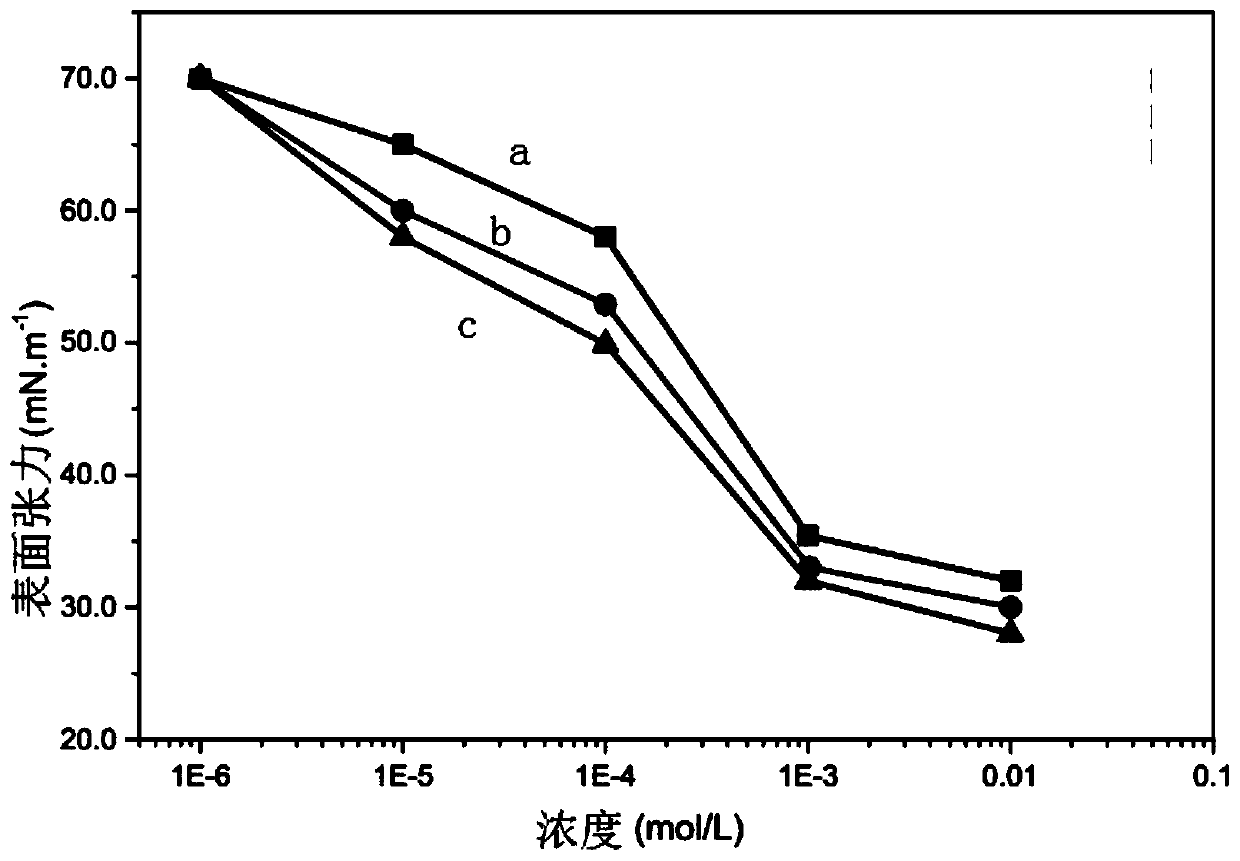

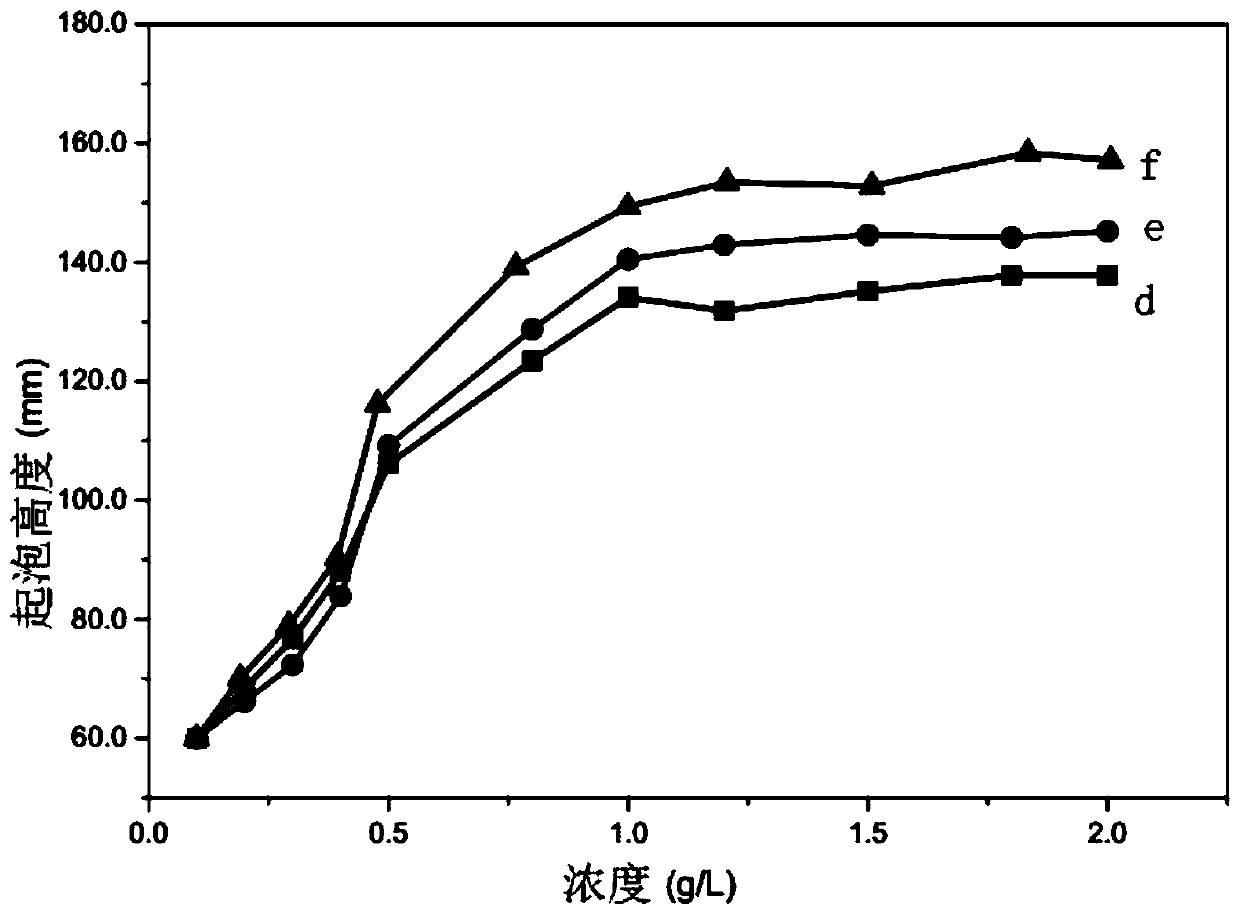

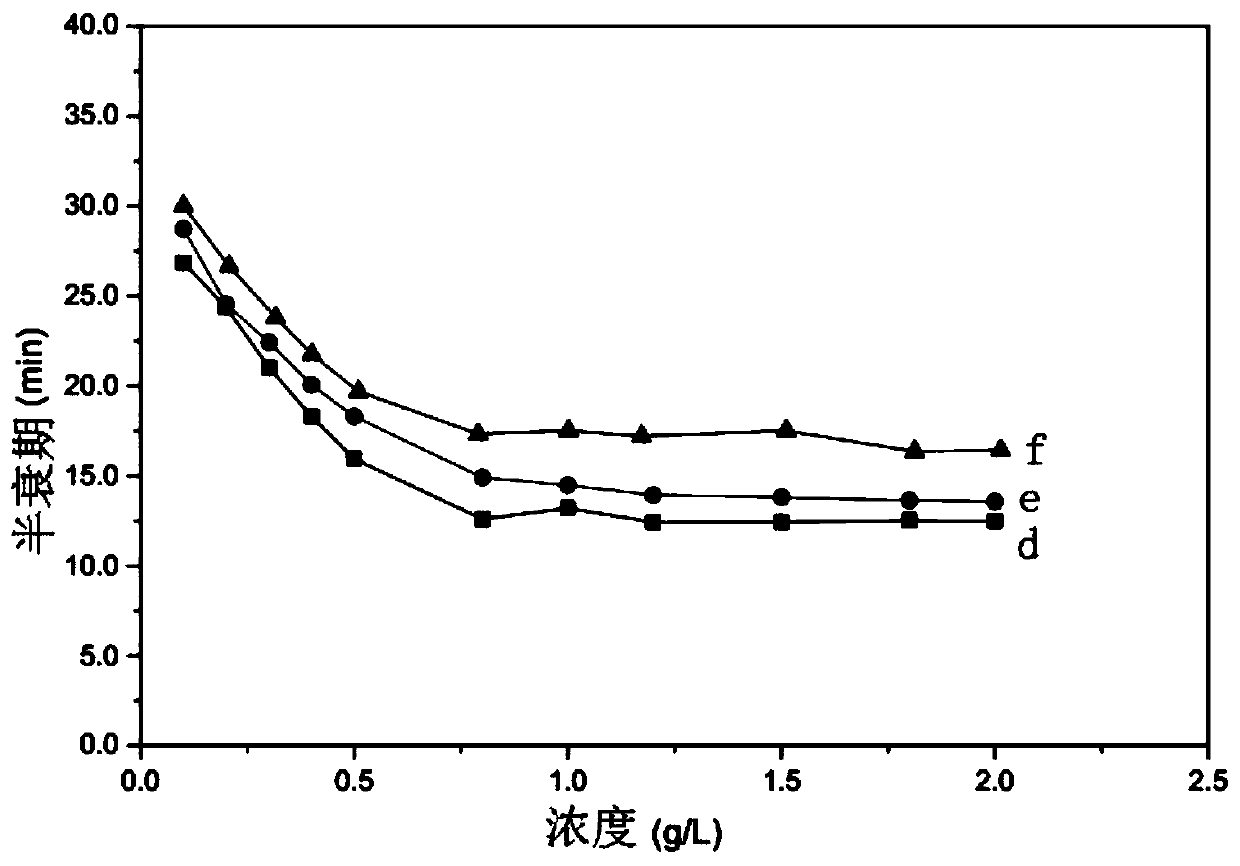

A technology of glycoside sulfobeet and surfactant, which is applied in the field of alkyl glycoside sulfobetaine type amphoteric surfactant and its preparation, and can solve the problem of poor water solubility, unsatisfactory performance and reduced foam performance of alkyl glycoside, etc. problems, to achieve good foam stability, good foaming and foam stability, and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The alkyl glycoside sultaine type amphoteric surfactant of the present embodiment, the structural formula of the alkyl glycoside sultaine type amphoteric surfactant is In the structural formula, n is an average degree of polymerization of 1.1 to 2.0, and R is an alkyl chain with 8 to 10 carbons.

[0022] This embodiment also provides a method for preparing the above-mentioned alkyl glycoside sulfobetaine type amphoteric surfactant, the method is:

[0023] S1, under the condition that the temperature is 50°C, in 150mL of acetone, add 32g of long-chain alkyl polyglycosides (0.05mol) of model APG0810, then add 6.75g of sulfonyl chloride (0.05mol) dropwise while stirring, The time for the dropwise addition is 0.5h, and react for 1h after the dropwise addition is completed, then add 4.38g of diethylamine (0.06mol) dropwise while stirring, the time for the dropwise addition is 0.5h, react for 4h after the dropwise addition, and cool naturally To room temperature, the long-c...

Embodiment 2

[0026] The alkyl glycoside sultaine type amphoteric surfactant of the present embodiment, the structural formula of the alkyl glycoside sultaine type amphoteric surfactant is In the structural formula, n is an average degree of polymerization of 1.1 to 2.0, and R is an alkyl chain with 8 to 14 carbons.

[0027] This embodiment also provides a method for preparing the above-mentioned alkyl glycoside sulfobetaine type amphoteric surfactant, the method is:

[0028] S1, under the condition that the temperature is 80°C, in 150mL of acetone, add 35g of long-chain alkyl polyglycosides (0.05mol) of model APG0814, then add 8.1g of sulfonyl chloride (0.06mol) dropwise while stirring, The time for the dropwise addition is 1h, and react for 1h after the dropwise addition is completed, then add 4.015g of diethylamine (0.055mol) dropwise while stirring, the time for the dropwise addition is 1h, react for 2h after the dropwise addition, and cool naturally to room temperature , to obtain a ...

Embodiment 3

[0031] The alkyl glycoside sultaine type amphoteric surfactant of the present embodiment, the structural formula of the alkyl glycoside sultaine type amphoteric surfactant is In the structural formula, n is an average polymerization degree of 1.1-2.0, and R is an alkyl chain with 12-14 carbons.

[0032] This embodiment also provides a method for preparing the above-mentioned alkyl glycoside sulfobetaine type amphoteric surfactant, the method is:

[0033] S1, under the condition that the temperature is 40°C, in 150mL of acetone, add 35g of long-chain alkyl polyglycoside (0.05mol) of model APG1214, then add 8.1g of sulfonyl chloride (0.06mol) dropwise while stirring, The time for the dropwise addition is 1h, and react for 1h after the dropwise addition is completed, then add 5.475g of diethylamine (0.075mol) dropwise while stirring, the time for the dropwise addition is 1h, react for 8h after the dropwise addition, and cool naturally to room temperature , to obtain a long-chai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com