Method for improving adsorption performance of ceramsite, modified ceramsite and application of modified ceramsite

A technology of adsorption performance and ceramsite, which is applied in the field of environmental material preparation, can solve the problems of high investment and large energy consumption, and achieve the effect of low cost, small economic investment and simple strengthening process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

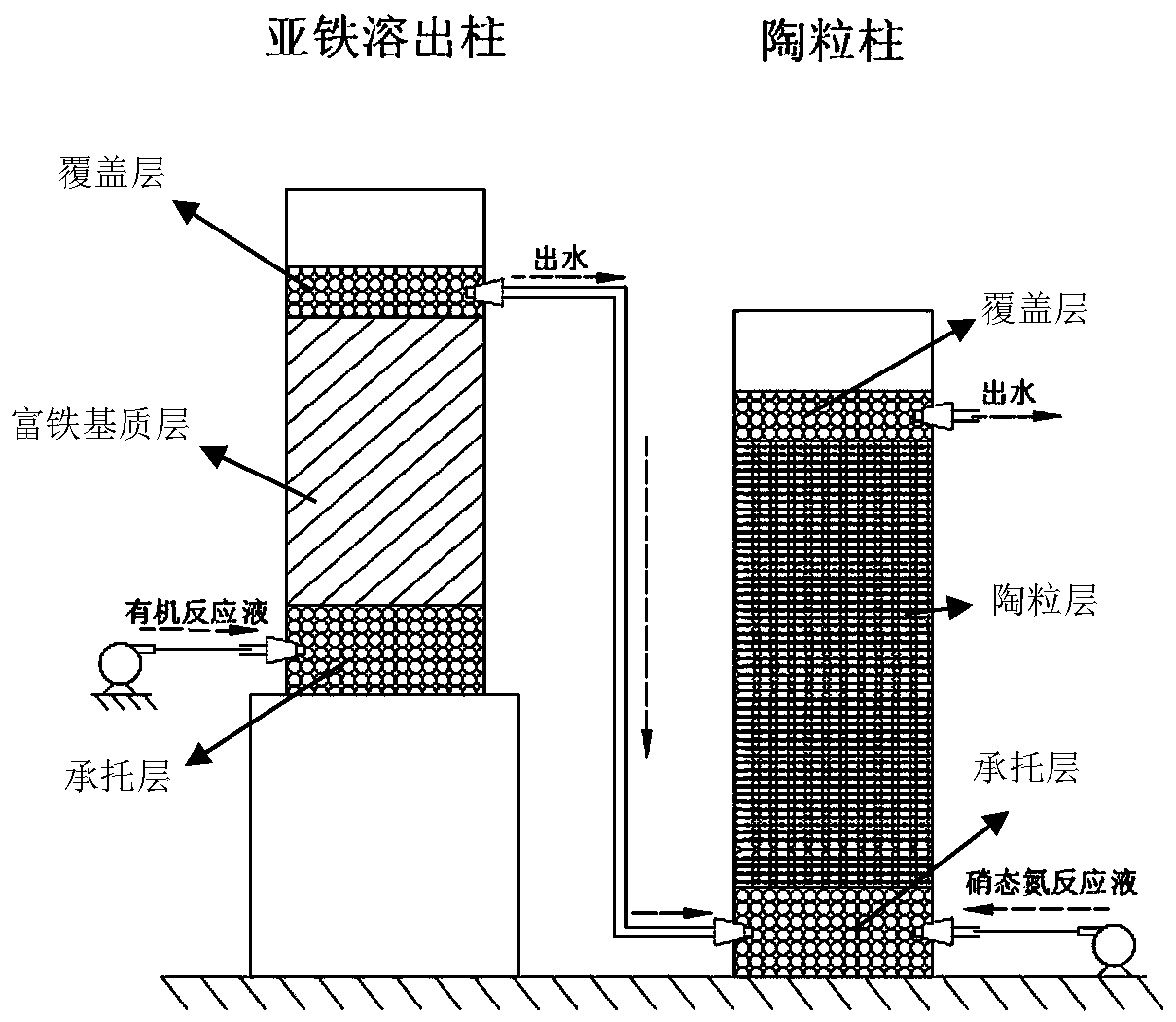

[0039] The construction of embodiment 1 reaction system

[0040] (1) Construction system: The material of the reaction column is PVC round pipe, which is divided into a ferrous dissolution column with a height of 52cm and a packing column (ceramic column) with a height of 67cm. The ferrous dissolution column uses iron-rich iron widely distributed in South China. The soil is used as the iron supply source of the system (iron-rich matrix layer), and the filler column (ceramsite column) contains ceramsite with a particle size of 1-2 cm to be modified, and its adsorption performance is poor;

[0041]A lower water inlet and an upper water outlet are respectively set at the positions of 4.5cm and 40cm from the bottom of the ferrous iron dissolution column, wherein the lower water inlet is used to input the iron reduction induction solution (solution containing organic matter) into the interior of the ferrous iron dissolution column , the upper water outlet is used to output ferrous-...

Embodiment 2

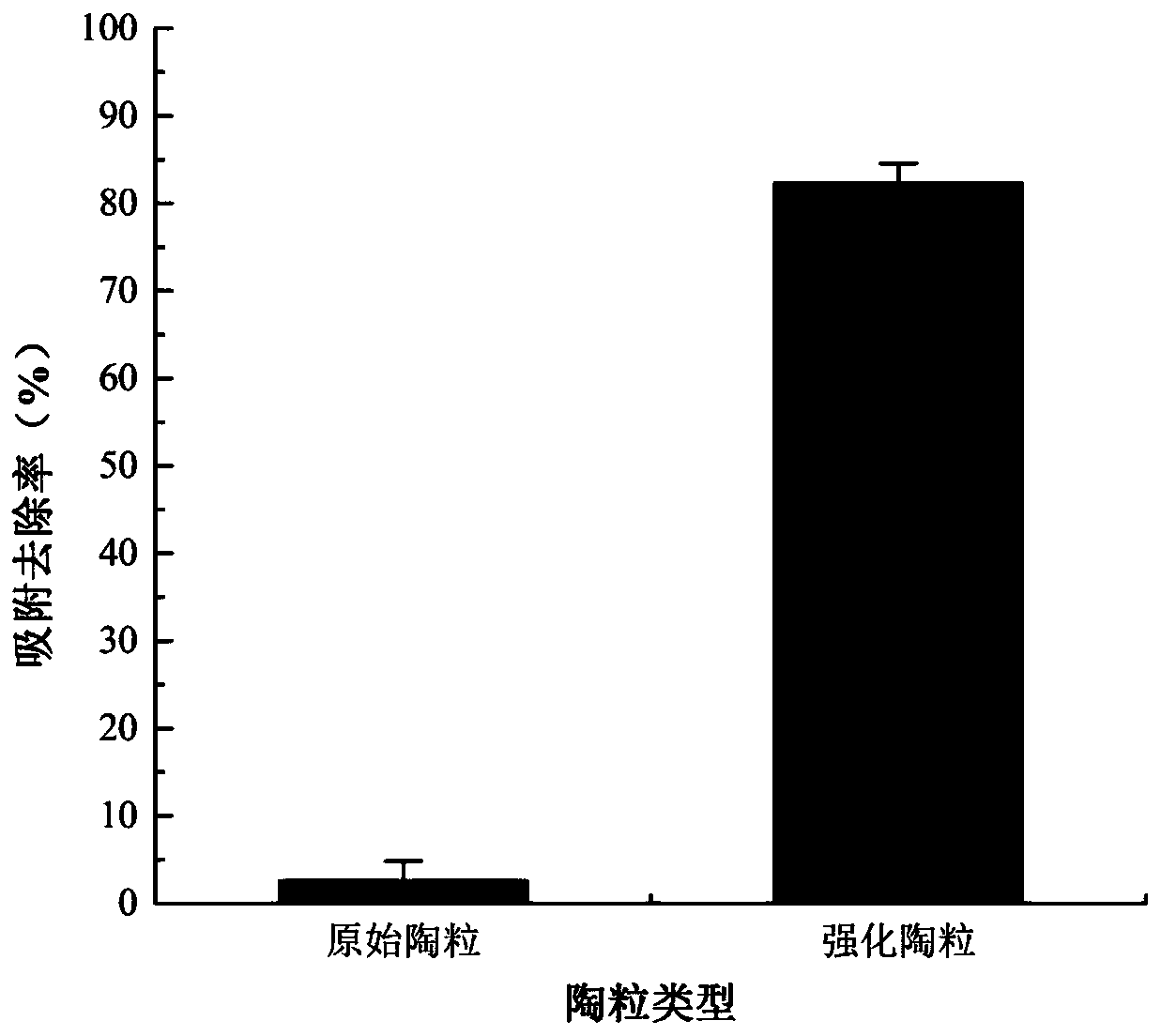

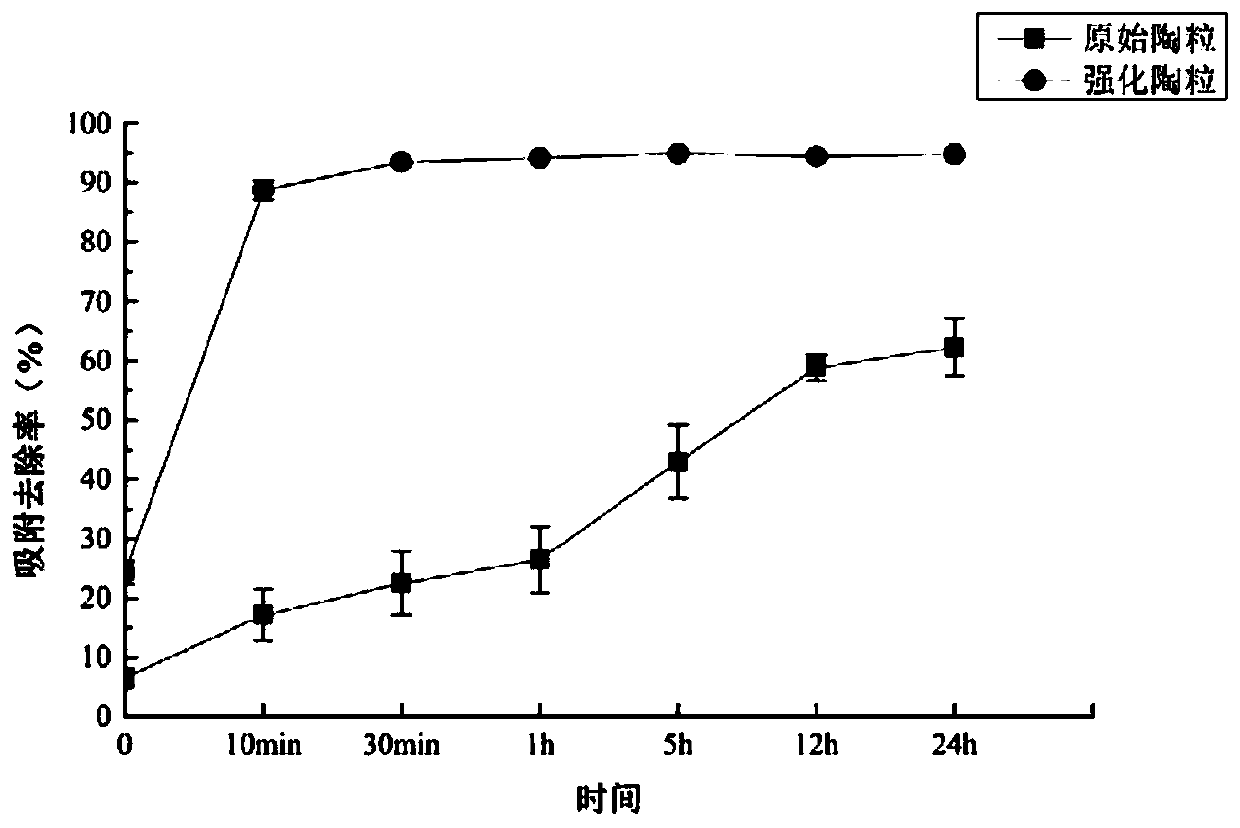

[0047] Example 2 Modified ceramsite adsorption of phosphorus and cadmium

[0048] The adsorption properties of modified ceramsite to phosphorus and cadmium in water were determined by static adsorption experiments. Using a 150mL Erlenmeyer flask as the adsorption device, according to the first-level discharge standard of "Pollutant Discharge Standards for Urban Sewage Treatment Plants" (GB18918-2002) and the "Electroplating Pollutant Discharge Standards" (GB21900-2008) water pollution discharge limits for newly-built enterprises Value preparation of phosphorus and cadmium reaction solution. The original ceramsite and the modified ceramsite (the total iron content of the modified ceramsite in Example 1=93.1~103mg / g) were tested respectively for their adsorption and removal performance, wherein the solid-liquid ratio was 5: 100 (mass ratio). After shaking at 25°C, 150r / min, and pH=7 for 24 hours, measure the remaining total phosphorus (TP) and Cd in the solution. TP is determin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com