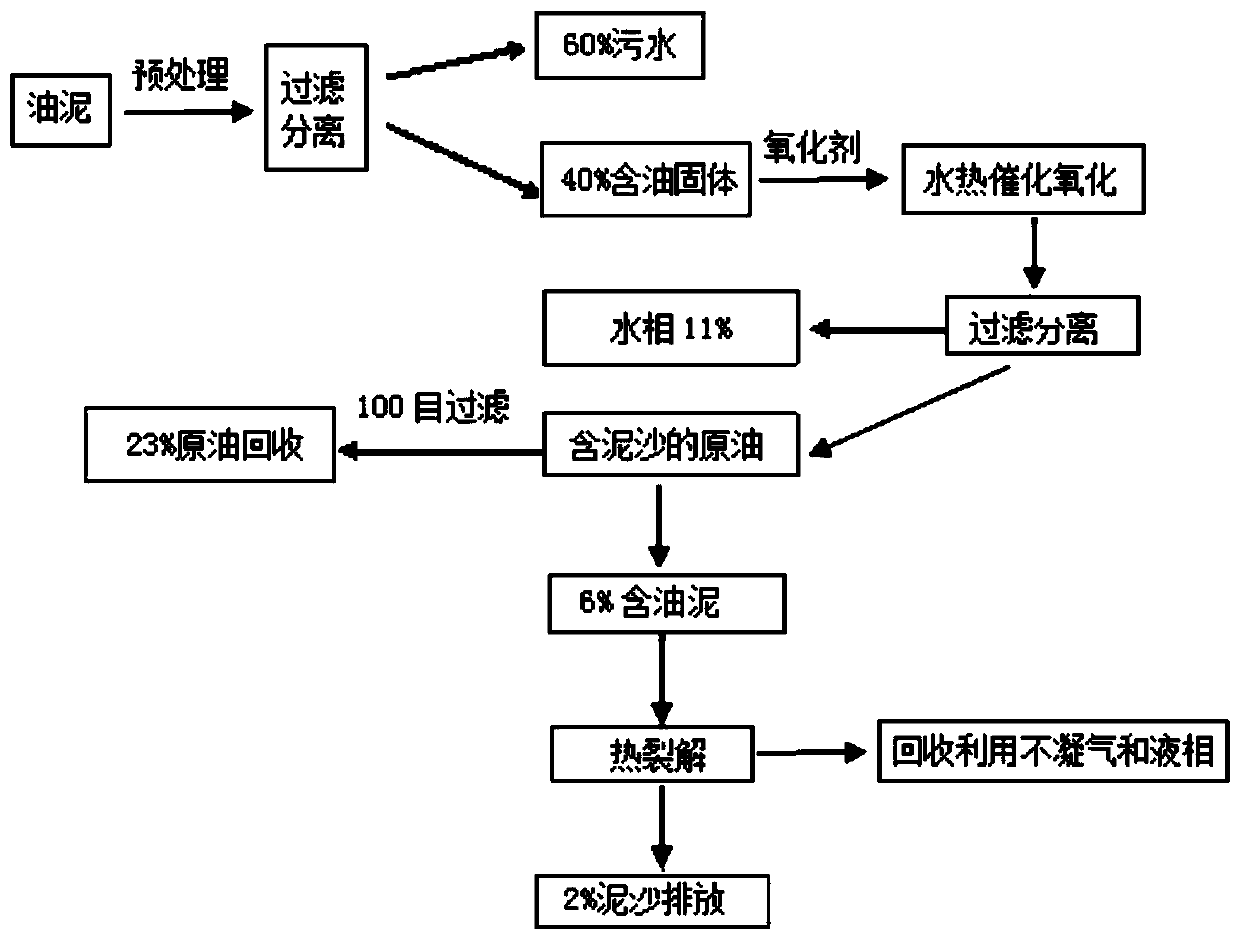

Method for treating irrigation sediment by using surfactant pretreatment-hydrothermal oxidation-thermal cracking coupling method

A surfactant and hydrothermal oxidation technology, applied in the chemical industry, can solve the problems of high energy consumption and high processing costs, and achieve the effects of low equipment requirements, reduced processing costs, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] The oil sludge sample collected at Linpan Linzhong Station is processed according to the method of the present invention, and the tank bottom oil taken from the Linzhong Station site has a basic composition as shown in Table 1:

[0036] Table 1

[0037] Moisture % Oil % Mud % 79 18 3

[0038] The concrete steps that process according to the inventive method are as follows:

[0039] The first step: oil sludge pretreatment

[0040] 50g of tank bottom oil sludge collected on site and 1g of hexadecyl ammonium bromide are fully mixed and stirred, and left to stand for 30 minutes to separate the mud and water, and filtered to obtain oil sludge and 30g of clear oil-free sewage. The clear oil-free sewage is as follows figure 2 As shown, the sludge photo is as image 3 shown.

[0041] The second step operation: filter cake hydrothermal oxidation

[0042] Weigh 20g of the obtained filter cake, add 1.5g of ammonium nitrate and 5g of water, carry out h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com