Bright flame type smokeless sulfur-free firecracker nitrate medicament and preparation method thereof

A bright, firecracker nitrate technology, applied in non-explosive stabilizers, non-explosive/non-thermal agent components, explosives, etc., can solve problems such as smoke pollution, achieve full combustion, simple process, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

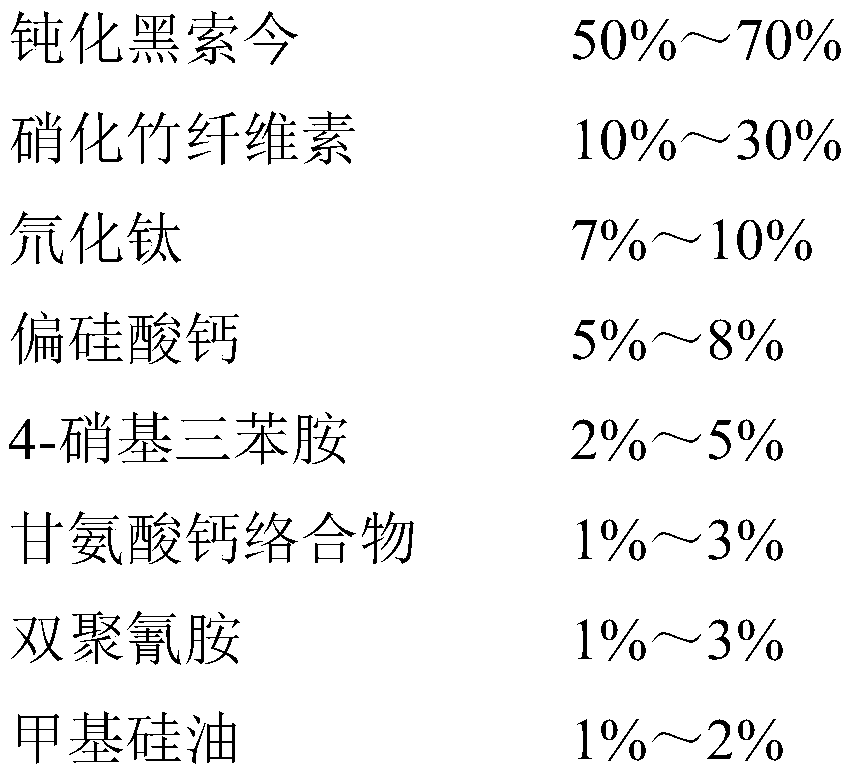

[0024] A kind of smokeless and sulfur-free firecracker nitrate agent with bright flame, the mass percentage of each component is as follows:

[0025]

[0026] Take 153.43g of nitrobamboo cellulose powder and divide it into two groups, A and B, wherein 33.43g of group A and 120g of group B, and dissolve the nitrobamboo cellulose powder of group A in 343.3g of ethyl acetate, and stir under the condition of ultrasonic dispersion 2 hours, then continue under stirring state, add 9.51g dipolycyandiamide, 17.86g4-nitrotriphenylamine, stir evenly, make nitrocellulose mixed sol;

[0027] In the state of stirring and ultrasonic dispersion, 343.87g of passivated hexogen powder, 59.15g of deuterated titanium powder and group B nitrobamboo cellulose were added to the nitrobamboo cellulose mixed sol, and mixed evenly; then 44.84g of partial silicon Calcium acid calcium powder and 11.84g of calcium glycinate complex powder were mixed in and stirred for 2.5 hours; then 6.60g of methyl sili...

Embodiment 2

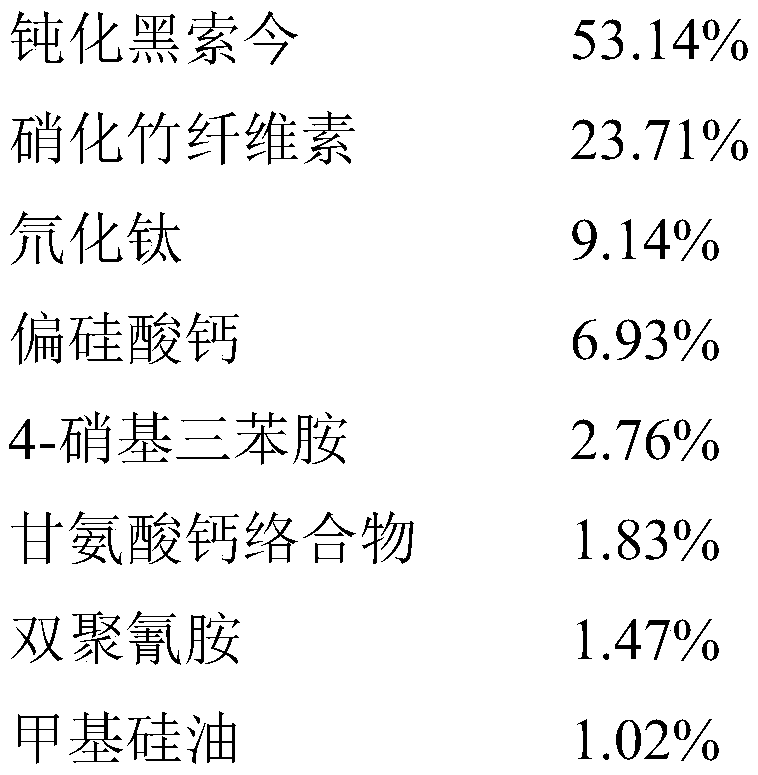

[0032] A kind of smokeless and sulfur-free firecracker nitrate agent with bright flame, the mass percentage of each component is as follows:

[0033]

[0034] Two groups of B, wherein A group is 5.41kg, B group is 12kg, and group A nitrobamboo cellulose powder is dissolved in 54.1kg ethyl acetate, stirred for 2.5 hours under the condition of ultrasonic dispersion, then continue to add 2.14 kg under stirring state kg dicyandiamide, 3.20kg4-nitrotriphenylamine, stir evenly, make nitrocellulose mixed sol;

[0035] In the state of stirring and ultrasonic dispersion, 57.09kg of passivated RDX powder, 8.35kg of deuterated titanium powder and group B nitrobamboo cellulose were added to the nitrocellulose cellulose mixed sol, and mixed evenly; then 7.08kg of partial silicon Calcium acid calcium powder and 2.52kg calcium glycinate complex powder were mixed in and stirred for 2 hours; then 1.30kg methyl silicone oil was added and mixed evenly; then kneaded until it was a uniform gela...

Embodiment 3

[0040] A kind of smokeless and sulfur-free firecracker nitrate agent with bright flame, the mass percentage of each component is as follows:

[0041]

[0042]Take 21.15kg of nitrobamboo cellulose powder and divide it into two groups, A and B, wherein 6.15kg of group A and 16kg of group B, and dissolve the nitrobamboo cellulose powder of group A in 61.5kg of ethyl acetate, and stir under the condition of ultrasonic dispersion 2.5 hours, then continue under stirring state, add 2.19kg dicyandiamide, 6.16kg4-nitrotriphenylamine, stir evenly, make nitrocellulose mixed sol;

[0043] In the state of stirring and ultrasonic dispersion, add 90.82kg of passivated hexogen powder, 13.79kg of deuterated titanium powder and group B nitrobamboo cellulose into the nitrocellulose cellulose mixed sol, and mix evenly; then 8.45kg of partial silicon Calcium acid calcium powder and 3.57kg calcium glycinate complex powder were mixed in and stirred for 2.5 hours; then 1.88kg methyl silicone oil w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com