Preparation method of Ag/Cu alloy nanocluster and application of Ag/Cu alloy nanocluster in Ag<+> detection

A technology of alloy nanometers and mixtures, applied in the field of fluorescent probes, can solve the problems of high cost, complex preparation method of alloy nanoclusters, and unsatisfactory application effect of detection methods, and achieves low cost, good practical application value and good optical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation of DPA@Ag / Cu NCs fluorescent probe

[0041] Add 950 μL ultrapure water to the reagent bottle, then add DPA solution (100 mM, 800 μL), AgNO 3 solution (100 mM, 200 μL) and Cu(NO 3 ) 2 Solution (100 mM, 50 μL), mixed at room temperature, and finally placed on a magnetic stirrer while irradiating with UV light for 6 h, to prepare 2 mL of DPA@Ag / Cu NCs solution. Prepared sample DPA at room temperature @ The Ag / Cu NCs were placed for 12 h, then moved to a centrifuge tube and placed on the material tray of a freeze dryer and placed in a cold trap for 4 h to be pre-frozen. After lyophilization, the sample was taken out after 24 h of lyophilization, and the DPA@Ag / Cu NCs fluorescent probe was obtained, which was used for subsequent experiments.

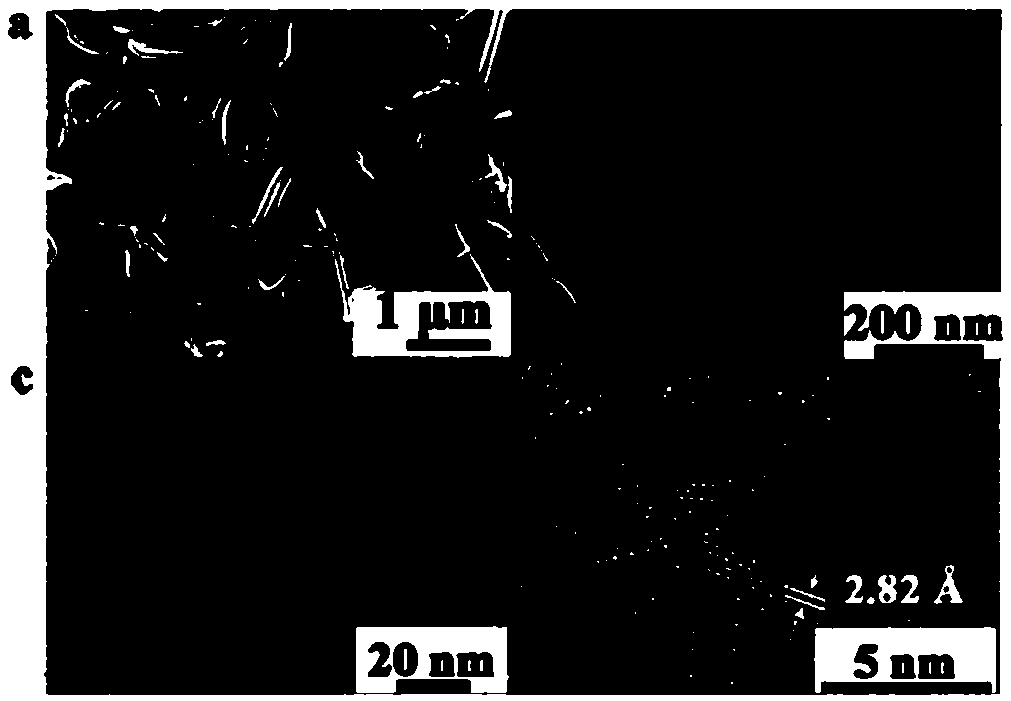

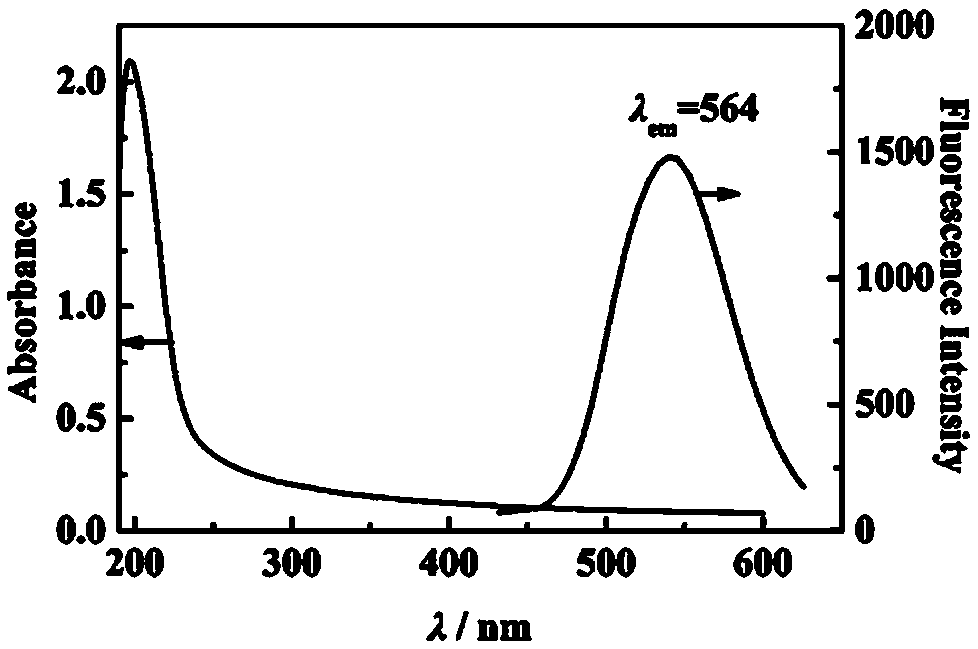

[0042] DPA@Ag / Cu NCs DPA @ Characterization of Fluorescent Probes for Ag / Cu NCs

[0043] For prepared DPA @ Ag / Cu NCs fluorescent probes use scanning electron microscopy (SEM), transmission electron microscopy (TEM),...

Embodiment 2

[0045] Ag in buffer + detection

[0046] Different concentrations of Ag + (0.05, 0.1, 0.5, 1, 5, 15, 30, 50, 80, 100, 200, 500, 800, 100, 1200, 1500 µM) were added to the prepared DPA @ Ag / Cu NCs fluorescent probe solution, then add phthalic acid-hydrochloric acid buffer solution to adjust the pH of the system to 2.8, incubate at room temperature for 30 min, and collect fluorescence emission in the range of 450-650 nm at an excitation wavelength of 353 nm Spectrum, and draw the standard curve, the result is as Figure 11 shown. When Ag + concentration in the range of 0-1500µM, with the Ag + As the concentration increases, the fluorescence intensity of the system decreases gradually, and the Ag + At high concentrations, fluorescence quenching gradually slows down. Figure 11 are different concentrations of Ag + The relationship diagram of the fluorescence change caused by it, the inset is the corresponding standard curve, and the results show that [Ag + ] and Δ F It h...

Embodiment 3

[0052] Experimental condition optimization

[0053] Change the UV lamp irradiation time in the preparation method of Example 1 (other conditions are the same as Example 1), and the results show that 6 h of irradiation is the best time ( Figure 10 a).

[0054] Changing DPA and AgNO 3 The dosage ratio and Cu(NO 3 ) 2 The dosage (other conditions are the same as Example 1), the results show that [Ag + ]:[DPA]=1:4( Figure 10 b) and [Cu 2+ ]=2.5 mM( Figure 10 c), the prepared DPA @ Ag / Cu NCs fluorescent probes have strong fluorescence intensity.

[0055] The influence of changing different buffer solutions and their pH on the fluorescence change of the detection system (other conditions are the same as in Example 2), DPA @ Ag / Cu NCs solution and Ag + In Britton-Robinson buffer solution (B.R buffer solution), phthalic acid-hydrochloric acid buffer solution (KHP-HCl buffer solution), glycine-hydrochloric acid buffer solution (Gly-HCl buffer solution), disodium hydrogen p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com