Soldering flux and preparation method thereof, solder paste and preparation method thereof

A flux and solder paste technology, applied in the direction of welding equipment, manufacturing tools, welding media, etc., can solve the problems affecting the consistency of solder paste viscosity, flux thixotropic performance and poor viscosity consistency, etc., to achieve good viscosity consistency and Stability, meeting surface mount requirements, anti-slump performance and good solderability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

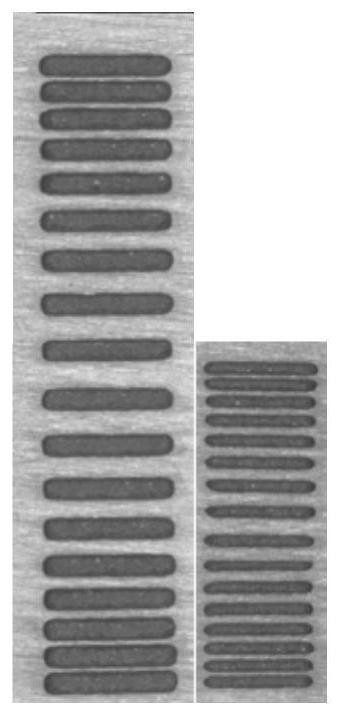

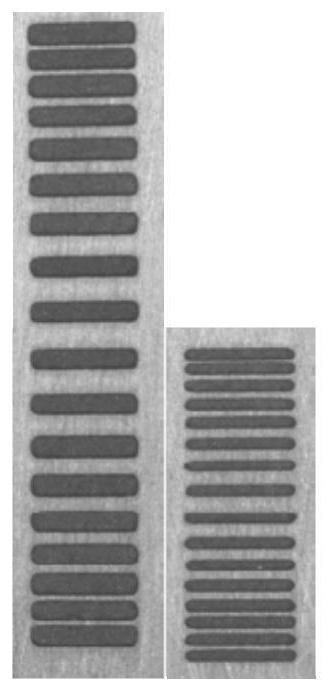

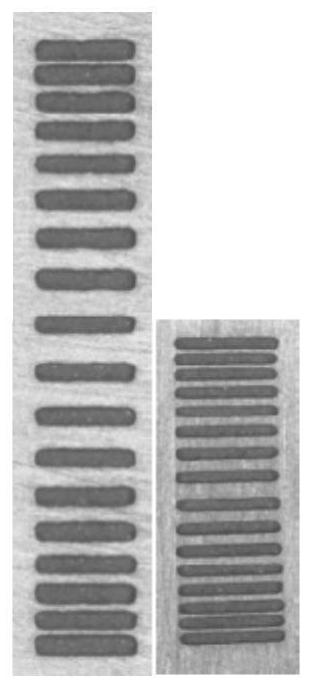

Image

Examples

preparation example Construction

[0069] The present invention also proposes a preparation method of flux, and the preparation method of described flux comprises the following steps:

[0070] According to parts by mass, provide 25-35 parts of solvent, 38-55 parts of film former, 8-20 parts of active agent and 5-10 parts of thixotropic agent;

[0071] mixing the solvent and the film-forming agent, and heating to obtain the first mixed solution;

[0072] cooling the first mixed solution, and adding an active agent to the cooled first mixed solution to obtain a second mixed solution;

[0073] A thixotropic agent is added to the second mixed solution to obtain a third mixed solution;

[0074] The third mixed solution is adjusted to a preset temperature threshold, kept warm, and then cooled to obtain flux.

[0075] Specifically, firstly, pour the solvent and the film-forming agent into a reaction kettle for mixing, heat to completely dissolve the film-forming agent, stir to mix evenly, and keep warm for a period ...

Embodiment 1

[0104] In terms of parts by mass, the flux contains 40.25 parts of diethylene glycol butyl ether, 30 parts of hydrogenated rosin, 10 parts of maleic rosin, 2 parts of ethylene stearic acid amide, 6 parts of phthalamide, and 2 parts of phenylsuccinic acid , 2 parts of DL-malic acid, 2 parts of adipic acid, 2 parts of dodecanoic acid, 2 parts of suberic acid, 1 part of benzotriazole and 0.75 parts of 2,6-di-tert-butyl-p-cresol.

[0105] Flux is prepared by the following steps:

[0106] (1) Add 40.25 parts of diethylene glycol butyl ether into the reaction kettle, and control the temperature of the reaction kettle to 95°C, the stirring speed is 300r / min, after stirring for 5min, add 30 parts of hydrogenated rosin and 10 parts of maleic rosin, Adjust the stirring speed to 1000r / min, keep warm for 30min, and obtain a clear and transparent first mixed solution.

[0107] (2) Reduce the temperature of the reactor to 75°C within five minutes, add 2 parts of phenylsuccinic acid, 2 part...

Embodiment 2

[0116] In terms of parts by mass, the flux contains 30.25 parts of diethylene glycol butyl ether, 10 parts of diethylene glycol hexyl ether, 10 parts of maleic rosin, 30 parts of water white rosin, 4 parts of hydrogenated castor oil derivatives, 4 parts of benzene Amide, 4 parts of succinic acid, 2 parts of phenylsuccinic acid, 2 parts of dodecanoic acid, 2 parts of suberic acid, 1 part of benzotriazole and 0.75 parts of 2,6-di-tert-butyl-p-methyl phenol.

[0117] Flux is prepared by the following steps:

[0118] (1) Add 30.25 parts of diethylene glycol butyl ether and 10 parts of diethylene glycol hexyl ether into the reaction kettle, and control the temperature of the reaction kettle to 95°C, and the stirring speed is 300r / min. After stirring for 5 minutes, add 10 parts Maleic rosin and 30 parts of water-white rosin, the stirring speed was adjusted to 1000r / min, and the temperature was kept for 30min to obtain a clear and transparent first mixed solution.

[0119] (2) Lowe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com