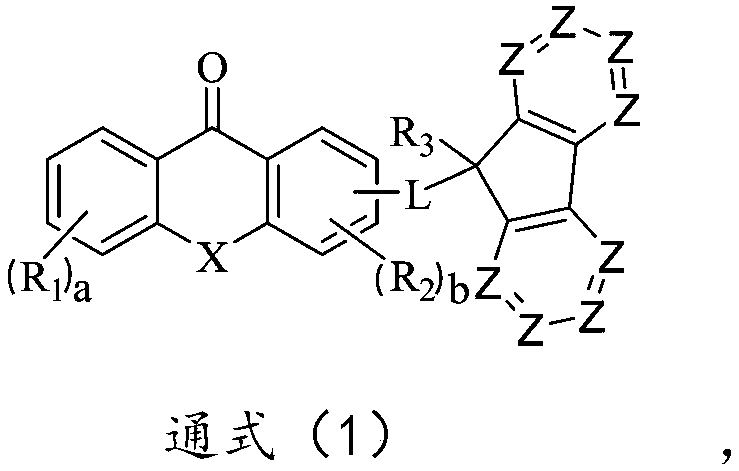

Compound taking ketone and fluorene as cores, and preparation method and application thereof

A compound, unsubstituted technology, used in chemical instruments and methods, organic chemistry, semiconductor/solid-state device manufacturing, etc., can solve problems such as different performance, achieve stable three-dimensional structure, improve luminous efficiency, and large steric hindrance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] Preparation of Intermediate A

[0074]

[0075] Under a nitrogen atmosphere, weigh raw material B and dissolve it in tetrahydrofuran (THF), then bis(pinacolyl)diboron, (1,1'-bis(diphenylphosphino)ferrocene)dichloropalladium ( II) Add potassium acetate, stir the mixture, heat the mixed solution of the above reactants to reflux at a reaction temperature of 70-90° C. for 5-10 hours; after the reaction is completed, add water to cool, and filter the mixture and dry it in a vacuum oven. The obtained residue was separated and purified through a silica gel column to obtain intermediate A;

[0076] Take the synthesis of intermediate A1 as an example:

[0077]

[0078] In a 250mL three-neck flask, blow nitrogen gas, add 0.02mol of raw material B1 and dissolve it in 150ml of tetrahydrofuran, then add 0.024mol of bis(pinacol radical) diboron, 0.0002mol of (1,1'-bis(diphenylphosphine) Ferrocene) dichloropalladium (II) and 0.05mol potassium acetate were added, the mixture wa...

Embodiment 1

[0084] Embodiment 1: the preparation of compound 1

[0085]

[0086] In a 250ml three-neck flask, add 0.01mol of raw material 1 and 0.015mol of intermediate A1, and dissolve in a mixed solvent of toluene, ethanol and water with a volume ratio of 2:1:1; under an inert atmosphere, add 0.02mol of Na 2 CO 3 Aqueous solution (2M), 0.0001mol Pd(PPh 3 ) 4 The mixed solution of the above reactants was reacted at a reaction temperature of 100°C for 15 hours, cooled and filtered the reaction solution, the filtrate was rotary evaporated, and passed through a silica gel column to obtain the target product with a HPLC purity of 99.90% and a yield of 76.8%. Elemental analysis structure (molecular formula C 44 h 28 o 2 ): Theoretical: C, 89.77; H, 4.79; O, 5.44; Tested: C, 89.77; H, 4.78; O, 5.43. HPLC-MS: The molecular weight of the material is 588.71, and the measured molecular weight is 588.70.

Embodiment 2

[0087] Embodiment 2: the preparation of compound 11

[0088]

[0089] The preparation method of compound 11 is the same as that in Example 1, except that raw material 2 is used to replace raw material 1, and intermediate A1 is replaced by intermediate A2. Elemental analysis structure (molecular formula C 44 h 28 o 2 ): Theoretical: C, 89.77; H, 4.79; O, 5.44; Tested: C, 89.78; H, 4.77; O, 5.43. HPLC-MS: The molecular weight of the material is 588.71, and the measured molecular weight is 588.74.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com