Perovskite/crystalline silicon laminated solar cell and preparation method thereof

A technology of solar cells and perovskite cells, which is applied in the field of solar cells, can solve problems such as the inability to prepare thin layers and the inability to prepare high-efficiency crystalline silicon/perovskite composite cells, and achieve excellent layered structures, improved efficiency, and light conversion high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

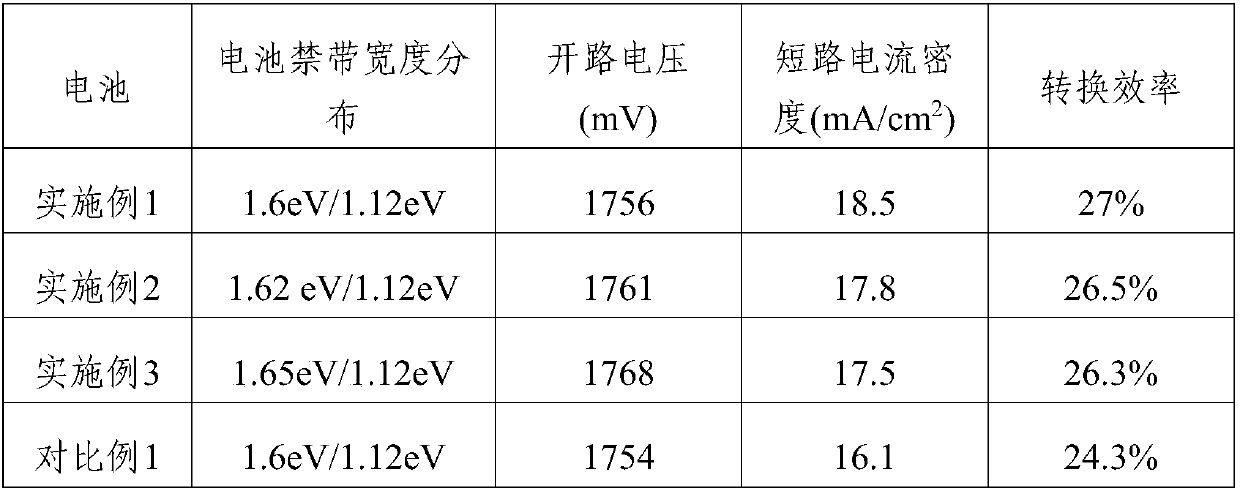

Embodiment 1

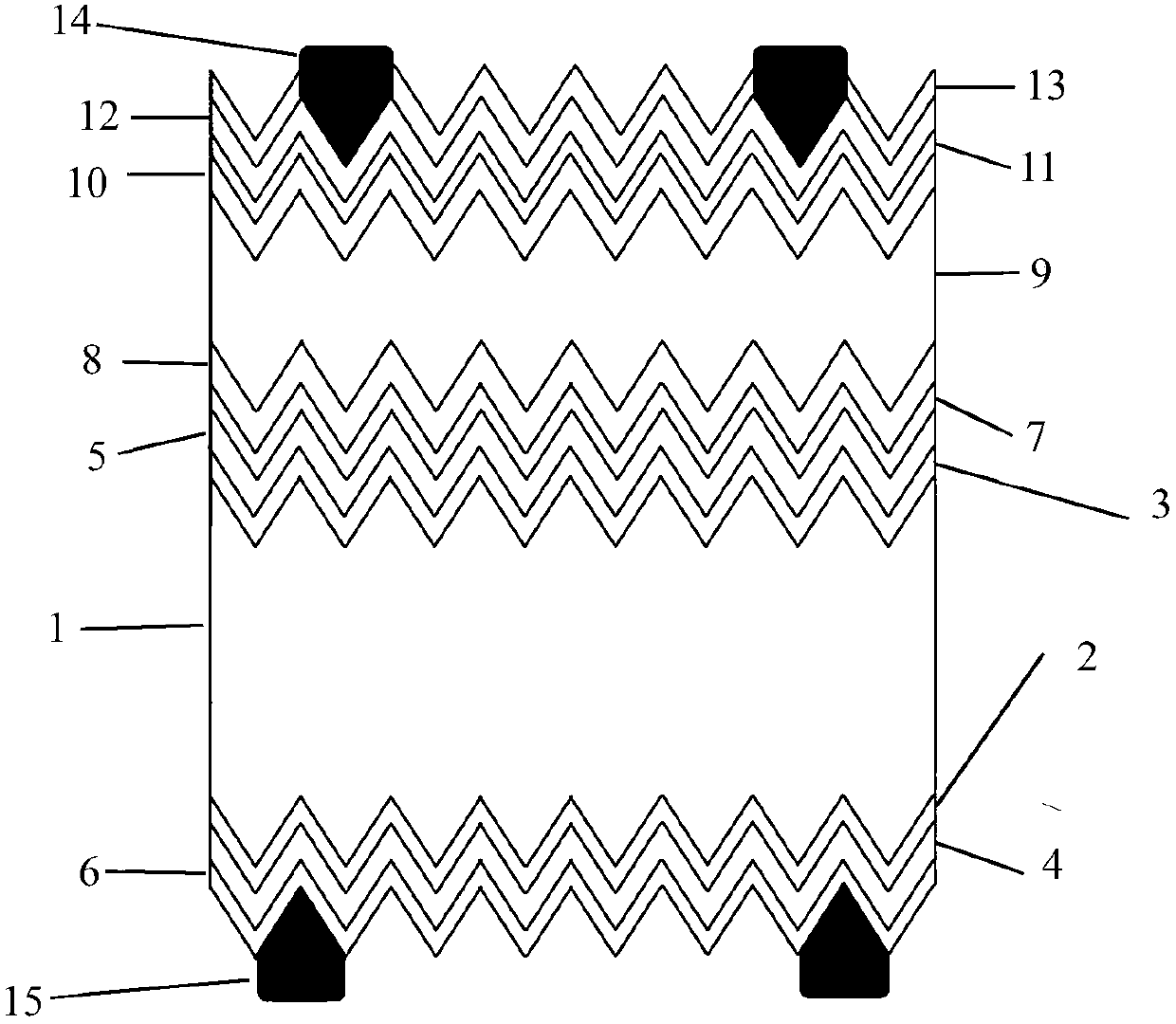

[0118] This embodiment relates to a perovskite / crystalline silicon laminated solar cell, and its specific structure is shown in figure 1 :

[0119] Including a crystalline silicon cell, a composite junction and a perovskite cell, the composite junction 7 is arranged between the crystalline silicon cell and the perovskite cell;

[0120] The crystalline silicon battery includes a crystalline silicon substrate 1, transparent conductive films a 6, p + poly-Si layer 4, the first tunneling layer SiO x 2. The second tunneling layer SiO x 3, and the n + poly-Si layer 5;

[0121] The first tunneling layer SiO x disposed on the first surface of the crystalline silicon substrate, the second tunneling layer SiO x It is arranged on the second surface of the crystalline silicon substrate, the first surface and the second surface of the crystalline silicon substrate are oppositely arranged, and the p + poly-Si layer is provided on the first tunneling layer SiO x away from the side ...

Embodiment 2

[0137] This embodiment relates to a perovskite / crystalline silicon laminated solar cell, which has the same layered structure as that of Embodiment 1, and the only difference lies in the specific selection and thickness of the materials of each layer, specifically:

[0138] The material of described transparent conductive film a is ITO, and the thickness of described transparent conductive film a is 180nm, p + The thickness of the poly-Si layer is 100nm, the first and second tunneling layer SiO x The thickness of the crystalline silicon substrate is 1.5nm, the thickness of the crystalline silicon substrate is 260 microns, n + The poly-Si layer has a thickness of 100 nm.

[0139] The hole transport layer is PEDOT-PSS, and its thickness is 400nm;

[0140] The material of the perovskite layer is MAPbI 3 , and its thickness is 450nm.

[0141] The material of the electron transport layer is PCBM, and its thickness is 100nm;

[0142] The material of the buffer layer is TiO 2 ,...

Embodiment 3

[0147] This embodiment relates to a perovskite / crystalline silicon laminated solar cell, which has the same layered structure as that of Embodiment 1, and the only difference lies in the specific selection and thickness of the materials of each layer, specifically:

[0148] The material of described transparent conductive film a is ITO, and the thickness of described transparent conductive film a is 180nm, p + The thickness of the poly-Si layer is 200nm, the first and second tunneling layer SiO x The thickness of the silicon substrate is 1.8nm, the thickness of the crystalline silicon substrate is 280nm, n + The poly-Si layer has a thickness of 200 nm.

[0149] The hole transport layer is NiO with a thickness of 200nm;

[0150] The material of the perovskite layer is MAPbBr 3 , and its thickness is 400nm.

[0151] The material of the electron transport layer is PCBM, and its thickness is 100nm;

[0152] The material of the buffer layer is Al-doped ZnO, and its thickness i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com