Antibacterial and wound healing promoting composition and medical hydrocolloid oil yarn thereof

A technology of wound healing and composition, which is applied in the field of antibacterial and wound healing promotion composition and its medical hydrocolloid oil yarn, which can solve the problems of lack of cohesion and inability to remove the dressing as a whole, so as to broaden the range of antibacterial and avoid Local concentration is too high, the effect of inhibiting Gram-negative bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

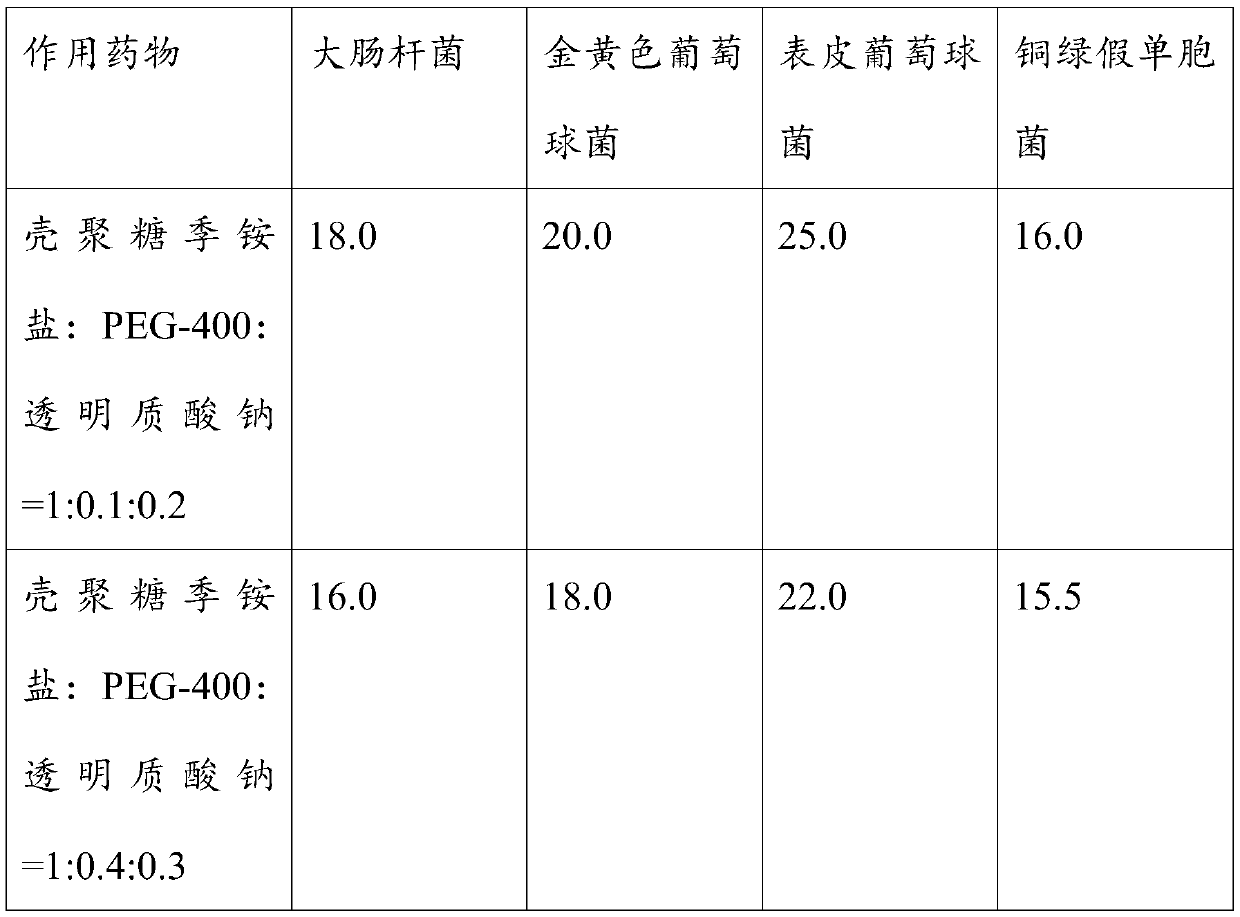

[0037] Embodiment 1, antibacterial and promote wound healing composition

[0038] group composition Composition 1 Chitosan quaternary ammonium salt: PEG-400: sodium hyaluronate = 1:0.1:0.2 Composition 2 Chitosan quaternary ammonium salt: PEG-400: sodium hyaluronate = 1:0.4:0.3 Composition 3 Chitosan quaternary ammonium salt: PEG-600: sodium hyaluronate = 1:0.6:0.4 Composition 4 Chitosan quaternary ammonium salt Composition 5 Sodium hyaluronate Composition 6 PEG-400 Composition 7 Chitosan quaternary ammonium salt: PEG-400=1:0.1

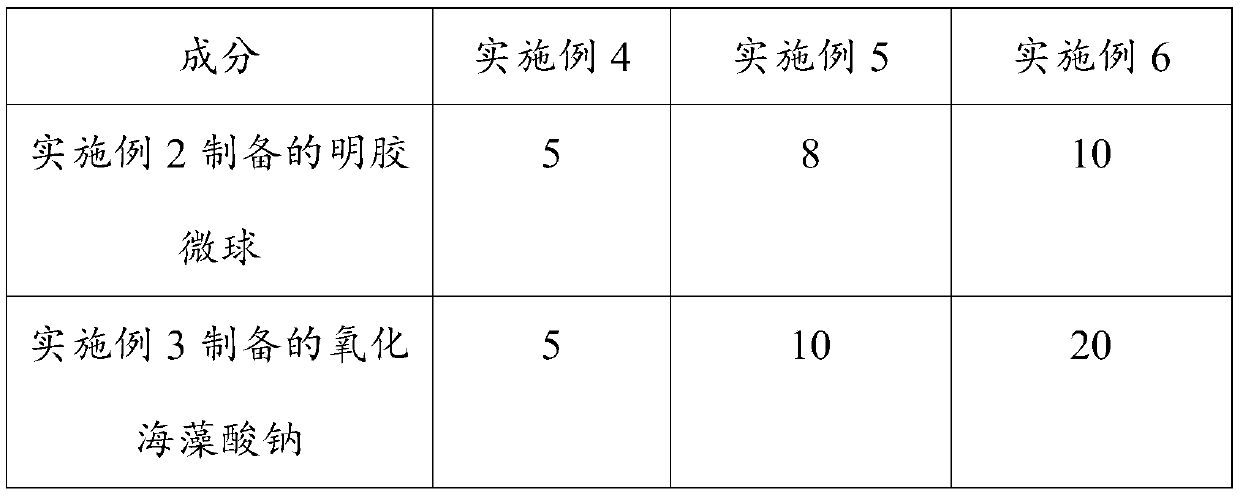

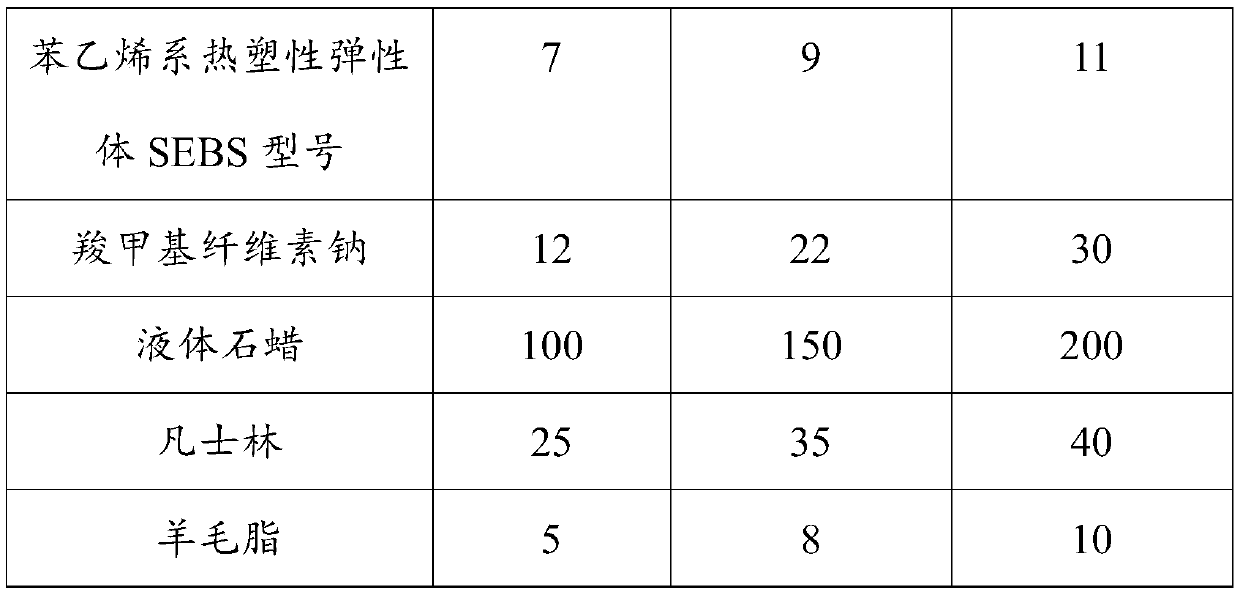

Embodiment 2

[0039] Embodiment 2, preparation of gelatin microspheres embedding antibacterial and promoting wound healing compositions

[0040] S1. Weigh gelatin and composition 1, add it into deionized water, stir at 60°C until completely dissolved, and obtain a solution with a concentration of 10%, which is used as the water phase;

[0041] S2. Add 60ml of vegetable oil into the beaker, then add 2ml of the mixture composed of Span 80 and Tween 80 in a mass ratio of 5:1 as an emulsifier, mix and preheat to 60°C, as the oil phase;

[0042] S3. Slowly add the water phase obtained in step S1 into the oil phase obtained in step S2. The volume ratio of the water phase to the oil phase is 1:5, mix evenly, and emulsify at a speed of 800r / min and a water bath temperature of 50°C 15min, a homogeneous emulsion was obtained;

[0043] S4. After emulsification, cool for 5 minutes, add 1 ml of glutaraldehyde solution with a concentration of 50% dropwise, and cross-link and solidify for 30 minutes to o...

Embodiment 3

[0045] Embodiment 3, preparation of oxidized sodium alginate

[0046] a. Sodium alginate is fully dissolved in pure water to obtain a 5wt% sodium alginate solution;

[0047] b. Slowly add the sodium periodate solution with a concentration of 0.5mol / L to the sodium alginate solution obtained in step a according to the volume ratio of 0.5:1. After reacting for 10 hours at room temperature in the dark, add 1ml of ethylene glycol to terminate the reaction. Stir for 1 hour to obtain oxidized sodium alginate solution;

[0048] c. Spray-dry the oxidized sodium alginate solution obtained in step b to obtain oxidized sodium alginate particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com