Puttying material with catalytic formaldehyde degradation and absorption function, and preparation method thereof

A technology for catalytic degradation and formaldehyde, applied in the direction of chemical instruments and methods, separation methods, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of poor air permeability and water absorption, low catalytic degradation efficiency, and inability to Fully contact with the air and other issues, to achieve the effect of wide application and good market prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

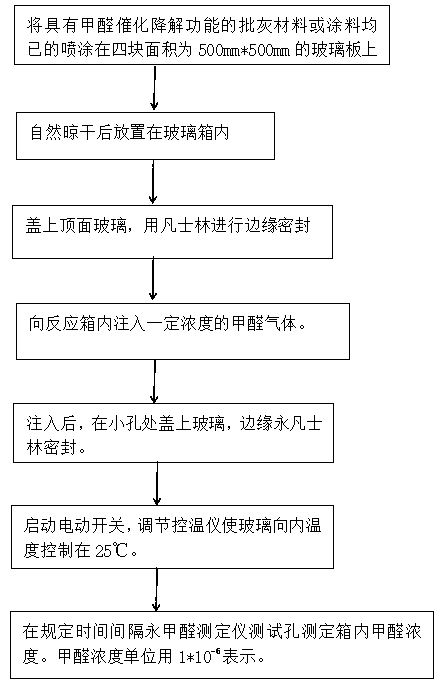

Image

Examples

Embodiment 1

[0019] Example 1: A kind of ash batch material with the function of catalytically degrading formaldehyde. The components of the raw materials are shown in Table 1.

[0020] A kind of preparation method of the batch ash material with catalytic degradation formaldehyde function is as follows:

[0021] Step 1, weighing polyvinyl alcohol and water, heating the water to 90°C to fully dissolve the polyvinyl alcohol;

[0022] Step 2, adding citric acid to the polyvinyl alcohol aqueous solution obtained in step 1, stirring evenly, fully dissolving the citric acid, and standing at room temperature for 48 hours;

[0023] Step 3: Add anatase-shaped titanium dioxide powder, gypsum, bamboo charcoal powder, and silicon dioxide to the aqueous solution of cross-linked polyvinyl alcohol, and stir evenly to obtain a dust-pigmented material with the function of catalytically degrading formaldehyde.

Embodiment 2

[0024] Example 2: A kind of ash batch material with the function of catalytically degrading formaldehyde. The components of the raw materials are shown in Table 1.

[0025] A kind of preparation method of the batch ash material with catalytic degradation formaldehyde function is as follows:

[0026] Step 1, weighing polyvinyl alcohol and water, heating the water to 90°C to fully dissolve the polyvinyl alcohol;

[0027] Step 2, adding hydrochloric acid dropwise to the polyvinyl alcohol aqueous solution obtained in step 1, so that the pH value is 3-4;

[0028] Step 3, adding sodium tetraborate and glutaraldehyde to the acidic polyvinyl alcohol aqueous solution obtained in step 2, stirring evenly, fully dissolving lemon and sodium tetraborate acid, and standing at room temperature for 12 hours;

[0029] Step 4, adding sodium bicarbonate dropwise to the cross-linked polyvinyl alcohol aqueous solution obtained in step 3, so that the pH value is 7-8;

[0030] Step 5: Add anatase-s...

Embodiment 3

[0031] Example 3: A kind of ash batch material with the function of catalytically degrading formaldehyde. The components of the raw materials are shown in Table 1.

[0032] A kind of preparation method of the batch ash material with catalytic degradation formaldehyde function is as follows:

[0033] Step 1, weighing polyvinyl alcohol and water, heating the water to 90°C to fully dissolve the polyvinyl alcohol;

[0034] Step 2, adding hydrochloric acid dropwise to the polyvinyl alcohol aqueous solution obtained in step 1, so that the pH value is 3-4;

[0035] Step 3, adding citric acid, sodium tetraborate, and glutaraldehyde to the acidic polyvinyl alcohol aqueous solution obtained in step 2, stirring evenly, fully dissolving lemon and sodium tetraborate acid, and standing at room temperature for 12 hours;

[0036] Step 4, adding sodium bicarbonate dropwise to the cross-linked polyvinyl alcohol aqueous solution obtained in step 3, so that the pH value is 7-8;

[0037] Step 5:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com