Method for preparing Mo-doped CdS photocatalyst by cation replacement method

A photocatalyst and displacement technology, which is applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., to achieve the effect of improving the photocatalytic reaction rate, requiring low preparation conditions, and promoting separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

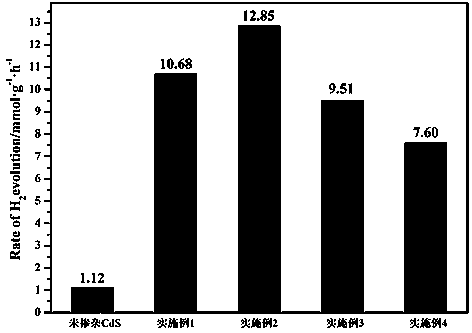

Embodiment 1

[0021] Weigh 4.7g (0.020mol) of cadmium acetate and 3.6g (0.032mol) of potassium thioacetate and dissolve them in 60mL of ethylene glycol. After stirring for 1 hour, transfer the resulting mixed solution into a 100mL polytetrafluoroethylene reactor , sealed with a steel sleeve and placed in a blast drying oven, heated to 180°C and kept for 24 hours, washed and dried the obtained yellow precipitate to obtain CdS nanorods; take 100mg (0.692mmol) CdS nanorods and disperse them in 100mL ethanol In, add 30mg (0.109mmol) MoCl 5 After dissolving, vigorously stirred in vacuum for 2 h, the obtained orange sample was washed and dried to obtain Mo-doped CdS nanorods.

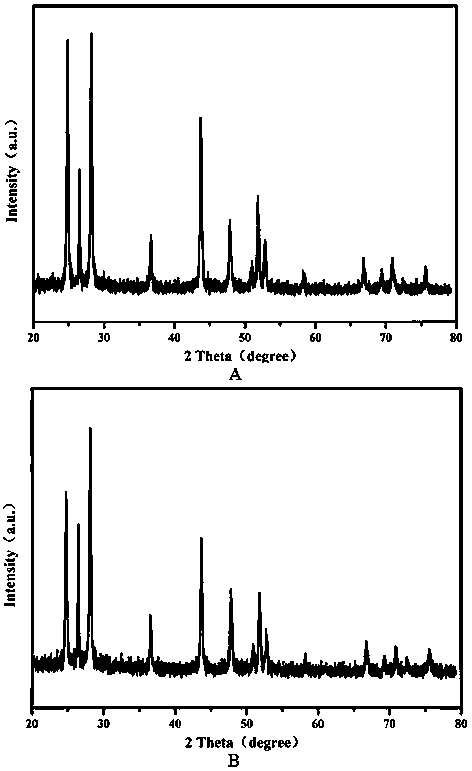

[0022] figure 1 It is the XRD comparison chart of the synthesized undoped CdS and Mo-doped CdS nanorods. It can be seen from the figure that the doping of Mo to CdS does not change the crystal phase structure of CdS.

Embodiment 2

[0024] Weigh 4.4g (0.019mol) of cadmium acetate and 6.4g (0.056mol) of potassium thioacetate and dissolve them in 60mL of ethylene glycol. After stirring for 1 hour, transfer the resulting mixed solution into a 100mL polytetrafluoroethylene reactor , packaged with a steel sleeve and placed in a blast drying oven, heated to 180°C and kept for 12 hours, washed and dried the obtained yellow precipitate to obtain CdS nanorods; take 100mg (0.692mmol) CdS nanorods and disperse them in 100mL ethanol In, add 100mg (0.367mmol) MoCl 5 After dissolving, vigorously stirred in vacuum for 2 h, the obtained orange sample was washed and dried to obtain Mo-doped CdS nanorods.

Embodiment 3

[0026] Weigh 16.0g (0.068mol) of cadmium acetate and 1.8g (0.016mol) of potassium thioacetate and dissolve them in 50mL of ethylene glycol. After stirring for 1 hour, transfer the resulting mixed solution into a 100mL polytetrafluoroethylene reactor , sealed with a steel sleeve and placed in a blast drying oven, heated to 160°C and kept for 12 hours, and the obtained yellow precipitate was washed and dried to obtain CdS nanorods; 100 mg (0.692 mmol) of CdS nanorods were dispersed in 100 mL of ethanol In, add 180mg (0.660mmol) MoCl 5 After dissolving, vigorously stir in vacuum for 1 h, wash and dry the obtained orange sample to obtain Mo-doped CdS nanorods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com