Polypropylene composite material and preparation method and application thereof

A technology for composite materials and polypropylene, which is applied in the field of polypropylene composite materials and its preparation, can solve the problems of reduced gloss, unsuitability for the preparation of high-gloss high flexural modulus PP composite materials, low flexural modulus, etc., and achieve rigidity and A well-balanced effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

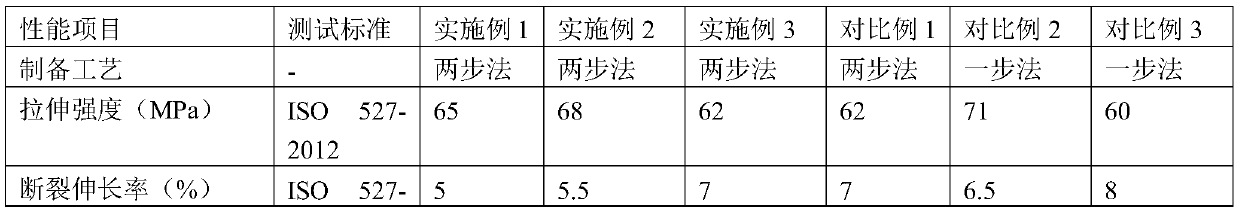

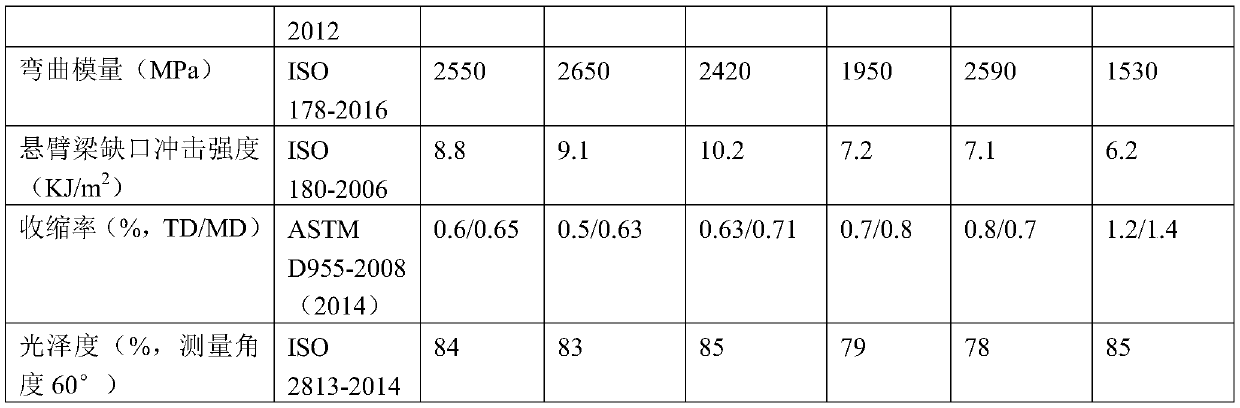

Examples

Embodiment 1

[0053] The low-shrinkage, high-bending modulus, and high-gloss engineering PP material provided by this embodiment that can replace ABS includes 20 parts by weight of the first PP (copolymerized PP BX3920, Korea SK Company, MI is 100g / 10min), 65 parts by weight Parts of the second PP (copolymerized PP R370Y, Korea SK company, MI is 18g / 10min), 20 parts by weight of GPPS (model GPPS 525), 5 parts by weight of SEBS (Baling Petrochemical, SEBS 602T), 5 parts by weight of Maleic anhydride grafted polypropylene (Westlake E43, the grafting ratio of maleic anhydride grafting is 13wt%), 15 parts of glass fibers (length 0.5mm, diameter 3 μm), 1.0 parts by weight of anti-glass fiber exposure agent TAF, 0.1 parts by weight 1010 parts by weight of antioxidant, 0.2 parts by weight of antioxidant 168, and 0.1 part by weight of isopropyl tris(isostearyl) titanate.

[0054] The preparation method of this polypropylene composite material comprises the following steps:

[0055] A. Production o...

Embodiment 2

[0059] The formula of the polypropylene composite material in this embodiment includes: 10 parts by weight of the first PP (copolymerized PP BX3920, Korea SK Company, MI is 100g / 10min), 70 parts by weight of the second PP (copolymerized PP R370Y, Korea SK Company, MI 18g / 10min), 20 parts by weight of PS, 5 parts by weight of SEBS (Baling Petrochemical, SEBS 602T), 8 parts by weight of maleic anhydride grafted PP (Westlake E43, the grafting rate of maleic anhydride grafted is 13wt %), 20 parts by weight of glass fiber (length 0.5mm, diameter 5 μ m), the anti-glass fiber exposure agent TAF of 1.0 parts by weight, the antioxidant 1010 of 0.1 parts by weight, the antioxidant 168 of 0.1 parts by weight Isopropyl tris(isostearyl) titanate.

[0060] Its preparation process is identical with embodiment 1.

Embodiment 3

[0062] The formula of the polypropylene composite material in this embodiment includes: 25 parts by weight of the first PP (copolymerized PP BX3920, Korea SK Company, MI is 100g / 10min), 50 parts by weight of the second PP (copolymerized PP R370Y, Korea SK Company, MI is 18g / 10min), 30 parts by weight of PS, 5 parts by weight of SEBS (Baling Petrochemical, SEBS 602T), 10 parts by weight of maleic anhydride grafted PP (Westlake E43, the grafting rate of maleic anhydride grafted 13wt%), 10 parts by weight of glass fiber (length 0.5mm, diameter 5 μm), 1.0 parts by weight of anti-glass fiber exposure agent TAF, 0.1 parts by weight of antioxidant 1010, 0.2 parts by weight of antioxidant 168, 0.1 parts by weight isopropyl tris(isostearyl) titanate.

[0063] Its preparation process is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Grafting rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com