High-molecular environment-friendly elastic sound insulation material and preparation method thereof

A sound insulation material and polymer technology, applied in the field of polymer environmental protection elastic sound insulation materials and its preparation, can solve the problems of inability to prepare large thickness coil products, reduce material hardness and flexural modulus, poor mechanical strength and flexibility, etc., to achieve Excellent filling ability, high sound insulation melt fluidity, good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

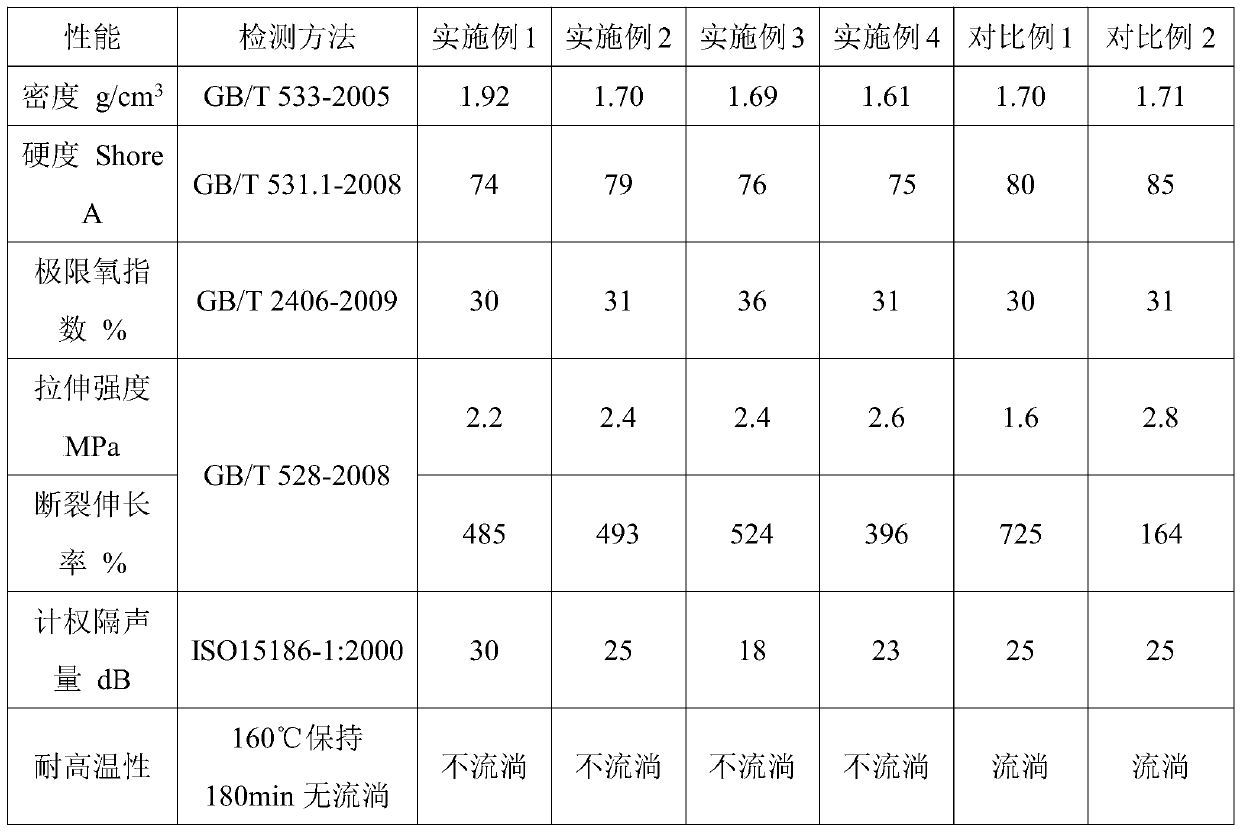

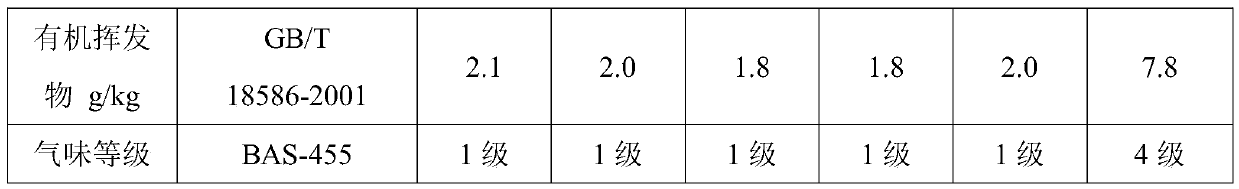

Examples

Embodiment 1

[0037] A polymer environment-friendly elastic sound-insulating material of the present invention comprises the following components in parts by weight:

[0038] 18 parts of acrylic elastomer,

[0039] Styrene elastomer 8 parts,

[0040] Barium sulfate 100 parts,

[0041] 6 parts naphthenic oil,

[0042] 2.5 parts of auxiliary agent,

[0043] 30 parts of aluminum hydroxide;

[0044] Among them, the propylene-based elastomer is a polyolefin copolymer of propylene and ethylene (VISTAMAXX 6202), the styrene-based elastomer is (Baling Petrochemical YH-502T), the particle size of barium sulfate is 600 mesh, and the naphthenic oil grade is KN4010. The auxiliary agent includes stearic acid, coupling agent and antioxidant, and its mass ratio is 1:1:0.5.

[0045] The preparation method of the above-mentioned polymer environment-friendly elastic sound insulation material comprises the following steps:

[0046] (1) Premix the styrene-based elastomer and the plasticizer in a disperse...

Embodiment 2

[0051] A polymer environment-friendly elastic sound-insulating material of the present invention comprises the following components in parts by weight:

[0052] Acrylic elastomer 15 parts,

[0053] 9 parts of styrenic elastomer,

[0054] 2 parts polypropylene,

[0055] 40 parts of barium sulfate,

[0056] 4 parts naphthenic oil,

[0057] Auxiliary 2 parts,

[0058] Aluminum hydroxide 25 parts,

[0059] 20 parts of magnesium hydroxide;

[0060] Among them, the propylene-based elastomer is a polyolefin copolymer of propylene and ethylene (VISTAMAXX 6202 and VISTAMAXX3000, the dosage is 12 parts and 3 parts respectively), the styrene-based elastomer is (Baling Petrochemical YH-502T), barium sulfate particles The diameter is 600 mesh, the grade of naphthenic oil is KN4010, the additives include stearic acid, coupling agent and antioxidant, and the mass ratio is 1:0.5:0.5.

[0061] The preparation method of the above-mentioned polymer environment-friendly elastic sound insul...

Embodiment 3

[0067] A polymer environment-friendly elastic sound-insulating material of the present invention comprises the following components in parts by weight:

[0068] 16 parts of acrylic elastomer,

[0069] 9 parts of styrenic elastomer,

[0070] 40 parts of barium sulfate,

[0071] 4 parts naphthenic oil,

[0072] Auxiliary 2 parts,

[0073] 35 parts of organic intumescent flame retardants;

[0074] Among them, the propylene-based elastomer is a polyolefin copolymer of propylene and ethylene (VISTAMAXX 6202 and VISTAMAXX 3000, the dosage is 12 parts and 4 parts respectively), the styrene-based elastomer is (Baling Petrochemical YH-502T), barium sulfate The particle size is 600 mesh, the grade of naphthenic oil is KN4010, the additives include stearic acid, coupling agent and antioxidant, and the mass ratio is 1:0.5:0.5.

[0075] The preparation method of the above-mentioned polymer environment-friendly elastic sound insulation material comprises the following steps:

[0076] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com