Method for preparing polyurea coating modified with end-capped polyetheramine

A technology of polyetheramine and polyurea, which is applied in the field of preparation of polyetheramine-modified polyurea materials, can solve the problems that polyurea cannot be painted by hand, and achieve excellent hygroscopic performance, high mechanical strength and strong antistatic property Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

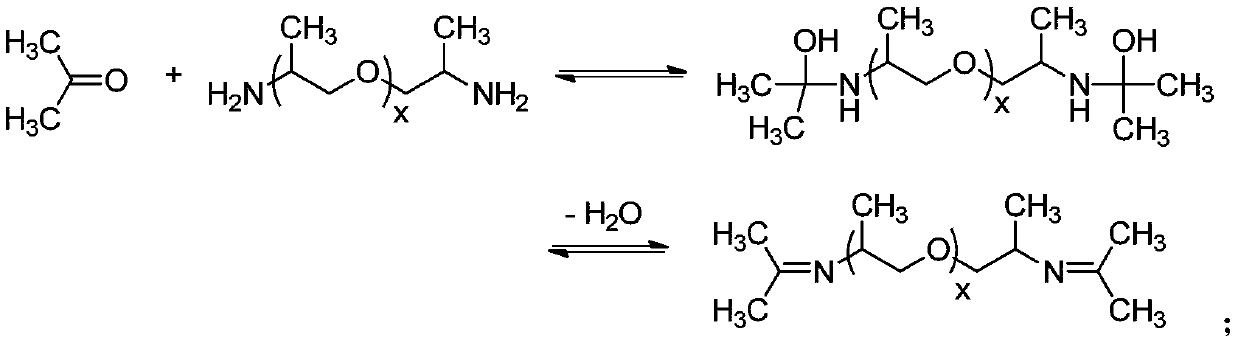

[0032] A method for preparing a modified polyurea coating with blocked polyetheramine comprises the following steps:

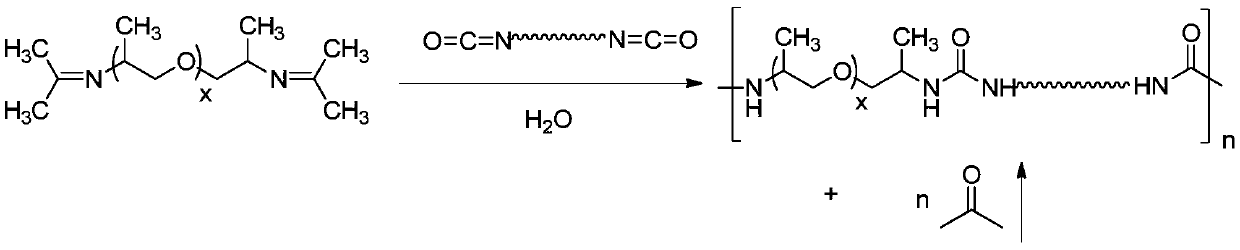

[0033] (1) Synthesis of ketimine: Add 35g of methyl isobutyl ketone into a 500mL three-neck flask equipped with a constant pressure dropping funnel, thermometer and stirrer, and add 200g of polyether dropwise when the temperature rises to 100°C Amine EDR-148, after the dropwise addition, the temperature is raised to 105-110°C, and the reaction is kept for 1-2 hours. Then remove the constant pressure dropping funnel, install a water separator, fill the water separator with methyl isobutyl ketone, an azeotropic solvent, raise the temperature and azeotrope, and control the water separation rate to 1-2 drops / second. Distillation under reduced pressure gave the ketimine when no more water flowed out.

[0034] (2) Preparation of polyurea coating: mix the isocyanate component and amino component in a molar ratio of 2:1, brush the obtained coating on the substrate at...

Embodiment 2

[0037] A method for preparing a modified polyurea coating with blocked polyetheramine comprises the following steps:

[0038] (1) Synthesis of ketimine: Add 35g of methyl isobutyl ketone into a 500mL three-neck flask equipped with a constant pressure dropping funnel, thermometer and stirrer, and add 180g of polyether after dehydration dropwise when the temperature rises to 100°C Amine EDR-176, after the dropwise addition, the temperature is raised to 105-110°C, and the reaction is kept for 1-2 hours. Then remove the constant pressure dropping funnel, install a water separator, fill the water separator with methyl isobutyl ketone, an azeotropic solvent, raise the temperature and azeotrope, and control the water separation rate to 1-2 drops / second. Distillation under reduced pressure gave the ketimine when no more water flowed out.

[0039](2) Preparation of polyurea coating: mix the isocyanate component and amino component in a molar ratio of 2:1, apply the obtained coating to...

Embodiment 3

[0042] A method for preparing a modified polyurea coating with blocked polyetheramine comprises the following steps:

[0043] (1) Synthesis of ketimine: Add 30g of acetone into a 500mL three-neck flask equipped with a constant pressure dropping funnel, thermometer and stirrer, and add 192g of polyetheramine EDR-192 dropwise when the temperature rises to 100°C. After the dropwise addition, the temperature was raised to 105-110°C, and the temperature was kept for 1-2 hours. Then remove the constant pressure dropping funnel, install the water separator, fill the water separator with acetone, the azeotropic solvent, raise the temperature and azeotrope, and control the water separation rate to 1-2 drops / second. Distillation under reduced pressure gave the ketimine when no more water flowed out.

[0044] (2) Preparation of polyurea coating: mix the isocyanate component and amino component in a molar ratio of 2:1, brush the obtained coating on the substrate at 25°C, and place it at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dispersion | aaaaa | aaaaa |

| Dispersion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com