Plugging agent and plugging liquid for drilling fractured leakage

A plugging agent and drilling technology, applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problems of long thickening time of lost circulation, long thickening time of lost circulation, poor compatibility of drilling liquid, etc. , to avoid drilling fluid pollution, reduce treatment time, and achieve good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

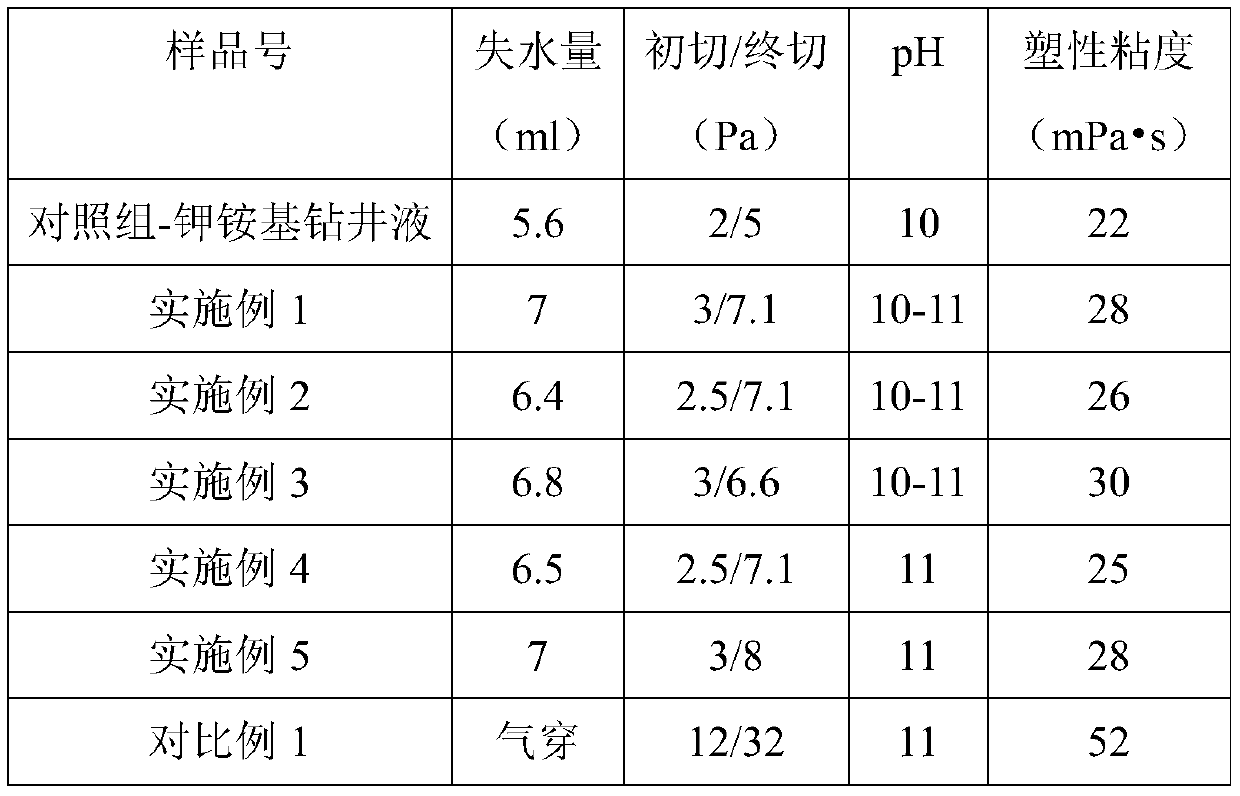

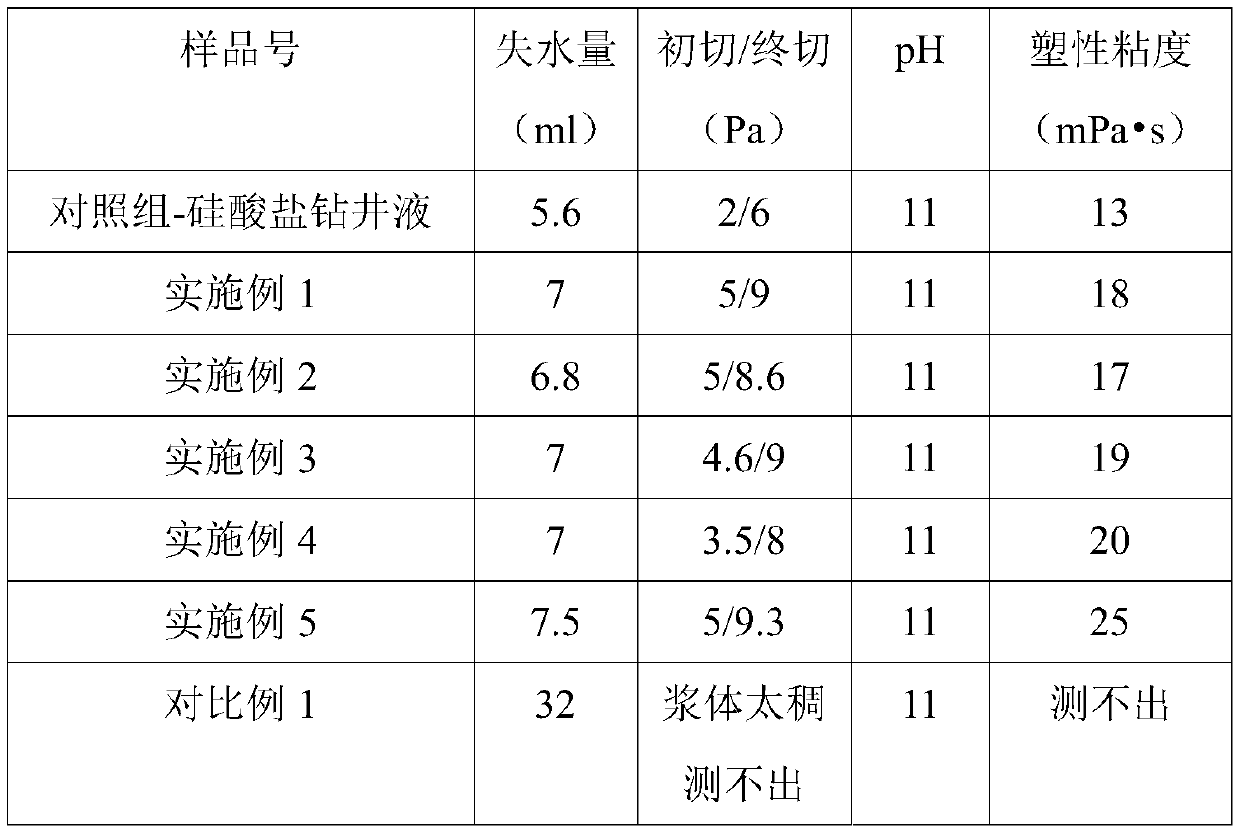

Embodiment 1

[0045] The lost circulation agent for drilling fracture loss in this embodiment is composed of the following components by weight: 100 parts of water slag, 20 parts of floating beads, 10 parts of silica fume, 5 parts of sodium hydroxide, and 2 parts of sodium carbonate , 2.5 parts of XJL-2, 3 parts of XJQ-2, 1 part of XJH-2, 1 part of sodium carboxymethyl cellulose, 2 parts of asbestos fiber with a length of 2 mm, 3 parts of glass fiber with a length of 6 mm, granules of water slag The diameter is 28-50 μm, the particle size of floating beads is 30-287 μm, and the particle size of micro-silicon powder is 0.312-11.197 μm.

Embodiment 2

[0047] The lost circulation agent for drilling fracture loss in this embodiment consists of the following components by weight: 100 parts of water slag, 15 parts of perlite, 15 parts of microsilica, 5 parts of sodium hydroxide, and 3 parts of sodium carbonate , 2.5 parts of XJL-2, 3 parts of XJQ-2, 1.3 parts of XJH-2, 1 part of polyacrylamide potassium salt, 3 parts of asbestos fiber with a length of 2mm, 3 parts of glass fiber with a length of 6mm, the particle size of water slag 28-50μm, the particle size of perlite is 60-400μm, and the particle size of micro-silica is 0.312-11.197μm.

Embodiment 3

[0049] The lost circulation agent for drilling fracture loss in this embodiment is composed of the following components by weight: 100 parts of water slag, 10 parts of glass microspheres, 15 parts of silica fume, 6 parts of sodium hydroxide, and 3 parts of carbonic acid Sodium, 1 part of sodium silicate, 2.5 parts of XJL-2, 3 parts of XJQ-2, 1.2 parts of XJH-2, 0.5 parts of sodium carboxymethylcellulose, 0.5 parts of potassium polyacrylamide, asbestos fibers with a length of 3 mm 2 Parts, 3 parts of glass fiber with a length of 6 mm, the particle size of water slag is 30-50 μm, the particle size of glass beads is 20-35 μm, and the particle size of micro-silica powder is 0.312-11.197 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com