Array chip mass spectrometry analysis method of photoelectrochemical reaction intermediate

An array chip, chemical reaction technology, applied in the field of mass spectrometry analysis, can solve problems such as difficult detection, restricting the development of photoelectric catalysis theory, catalyst development, short life of intermediates, etc., to achieve the effect of in-situ analysis, avoiding delay and avoiding influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

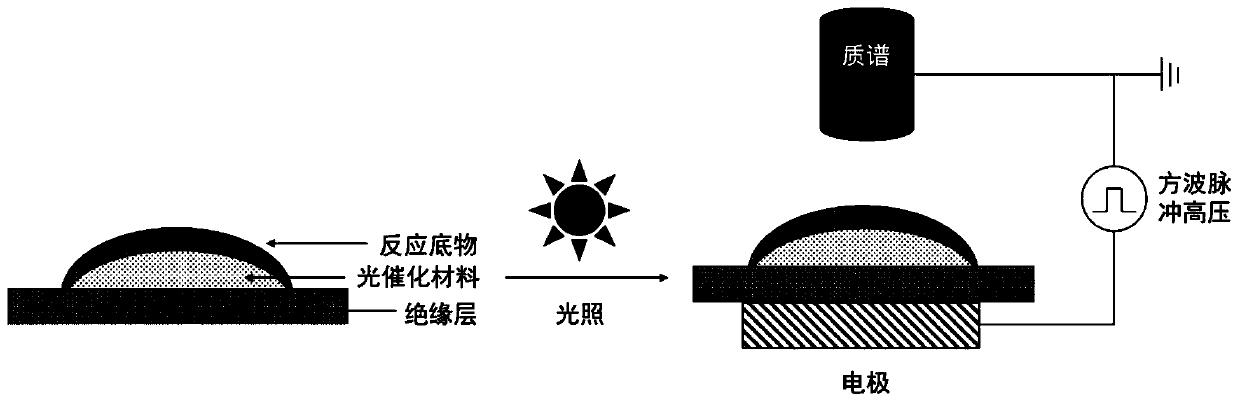

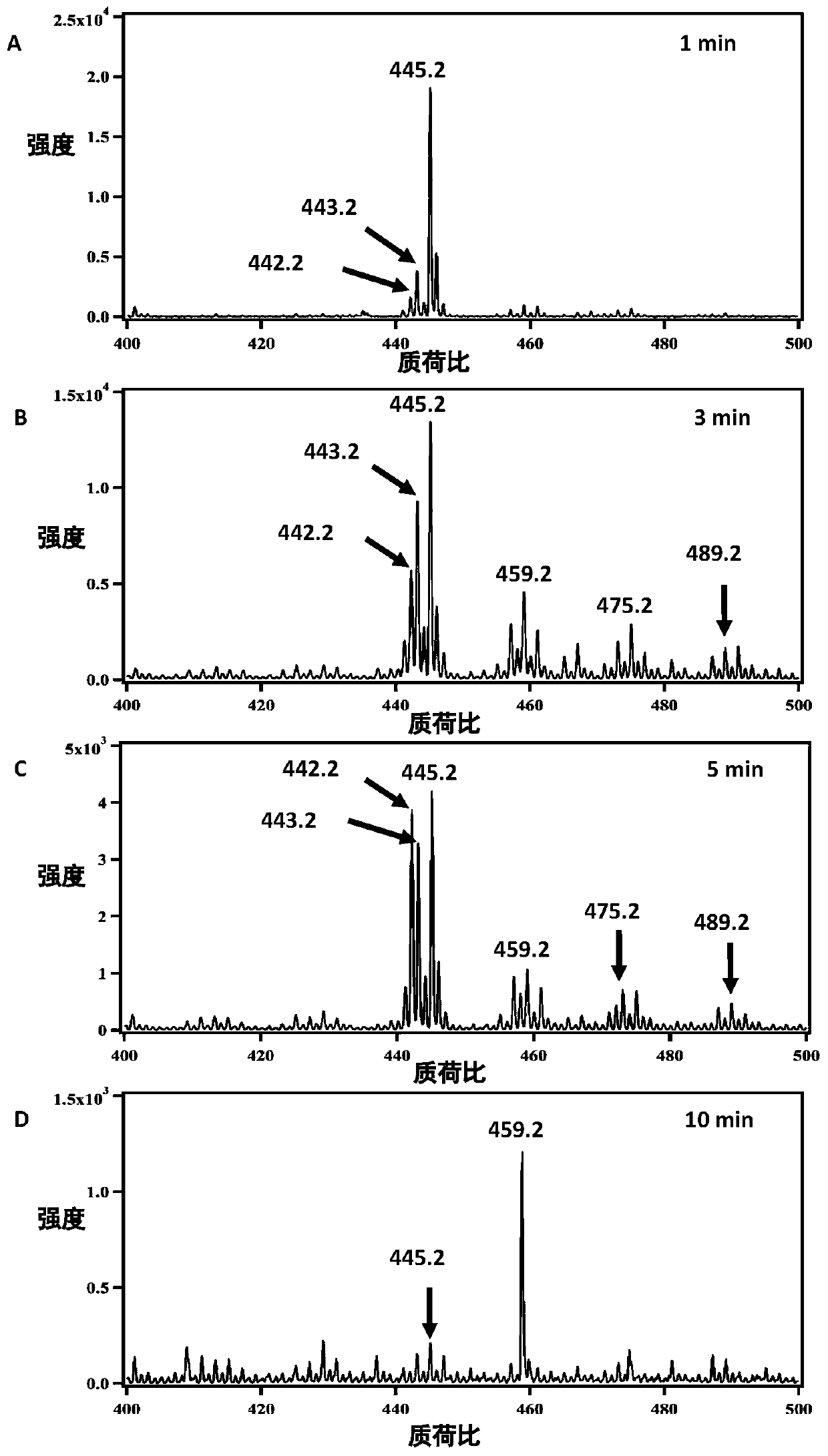

[0028] Detection of intermediates in mitoxantrone photooxidation reaction using titanium dioxide-modified array chip coupled with electrostatic spray ionization mass spectrometry. Include the following steps:

[0029] Take 0.1g of Degussa P25 titanium dioxide, grind it in a mortar for 1 hour, add 1 ml of 1% acetic acid dropwise during the grinding process, disperse the ground titanium dioxide powder in 1 ml of ethanol, and dilute it 25 times in water to obtain 4 milligrams per milliliter of titanium dioxide suspension. The suspension was modified on the glass surface by inkjet printing technology to form an array chip. The chips were burned at 400°C for one hour and cooled naturally.

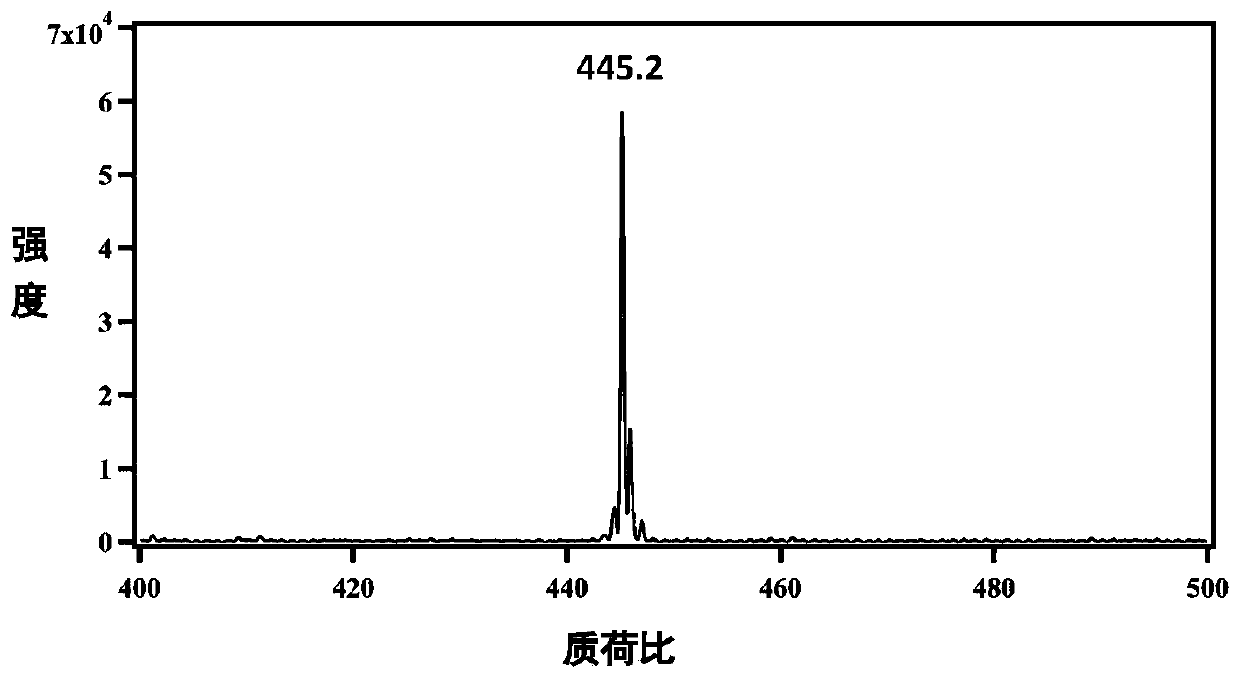

[0030] Add 0.4 millimoles per liter, 1 microliter of mitoxantrone aqueous solution dropwise on the surface of a glass sheet modified with titanium dioxide, and use electrostatic spray ionization mass spectrometry to directly detect it. The square wave pulse high voltage used in the detection i...

Embodiment 2

[0033] Detection of intermediates in photooxidation of mitoxantrone using graphene-modified polyimide array chip coupled with electrostatic spray ionization mass spectrometry.

[0034] Graphene oxide ink formulation: 3 mg of graphene oxide flakes (Nanjing Pioneer Nanomaterial Technology Co., Ltd.) and 50 mg of polyvinylpyrrolidone (PVP) powder were added to 1 mL of water:isopropanol (3:1) mixture, and Sonicate by on / off cycle at 35% amplitude for 180 min in a 2 mL centrifuge tube. The final dispersion concentration was 3 mg / ml of graphene oxide. Then, the dispersion was centrifuged at 13000 g Centrifuge for 20 minutes and remove the supernatant. Thereafter, the precipitate was redispersed in 1 ml of a 1,2-propanediol-based mixture containing 10% terpineol.

[0035] Use an inkjet printer to print the above ink onto the surface of a polyimide substrate (0.2 mm thickness) to form an array of dots with a diameter of 0.2 mm, and use light curing to stabilize the printed layer. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com