Method for recycling desulfurization byproduct of power plant

A desulfurization by-product, power plant technology, applied in the direction of thiosulfate/dithionite/polythionate, etc., can solve the problem of unsatisfactory data reproducibility, unstable properties of calcium sulfite, and reduced desulfurization efficiency and other problems, to achieve the effect of fewer types of chemicals, fewer types of equipment, and improved desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

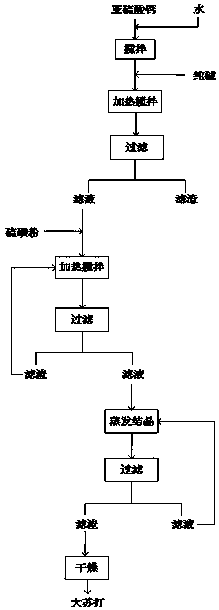

Image

Examples

Embodiment 1

[0021] Add 100g of calcium sulfite, 100g of soda ash, and 1L of deionized water into the reaction kettle, heat up to 60°C while stirring, react for 1 hour and then filter to obtain 940mL of filtrate. Put the filtrate and 300g of sublimed sulfur into the reactor and heat to 90°C, stir and react for 2 hours, then filter to obtain 860mL of filtrate, put the filtrate into the crystallization kettle and evaporate it under reduced pressure for 1 hour, the pressure of the crystallization kettle is -0.01MPa, and the temperature is 30°C. After drying, the obtained filter residue was soda, with a weight of 122.4 g.

Embodiment 2

[0023] Add 120 g of calcium sulfite, 106 g of soda ash, and 1.5 L of deionized water into the reaction kettle, heat and stir at 100° C. for 1 hour, and then filter to obtain 1.36 L of filtrate. Put the filtrate and 400 g of sublimed sulfur into the reactor, heat and stir at 105°C for 2 hours, then filter to obtain 1.2 L of filtrate. The filtrate was added to the crystallization kettle and evaporated under reduced pressure for 1 hour. The pressure of the crystallization kettle was -0.005MPa, and the temperature was 40°C. After drying, the obtained filter residue was soda, weighing 152.7g.

Embodiment 3

[0025] Add 100 g of calcium sulfite, 150 g of soda ash, and 2 L of deionized water into the reaction kettle, heat and stir at 110° C. for 1 hour, and then filter to obtain 1.14 L of filtrate. The filtrate and 500 g of sublimed sulfur were put into a reaction kettle, heated and stirred at 110° C. for 2 hours, and then filtered to obtain 970 mL of filtrate. The filtrate was added to the crystallization kettle and evaporated under reduced pressure for 1 hour. The pressure of the crystallization kettle was -0.01MPa and the temperature was 50°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com