Preparation method and applications of chitosan polypeptide derivative self-cross-linking hydrogel taking oxidized hyaluronic acid as cross-linking agent

A technology for oxidizing hyaluronic acid and chitosan polypeptides, applied in the field of polymer chemistry, can solve problems such as hindering development and poor solubility, and achieve the effects of no biological toxicity, excellent swelling performance, and good blood compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Preparation of carboxymethyl chitosan (CMCS):

[0042](1) Alkalinization of chitosan (CS): Measure 20 mL of distilled water in a beaker, put into a magnetic stirrer to stir, add 20 g of NaOH solid, and prepare a 50% NaOH solution as an alkalizing agent for CS. After the NaOH solution was completely cooled, slowly add 20 g CS to it in batches, and stir with a glass rod while adding, until it became fluffy, and finally put it in a -5 °C refrigerator for 24 h.

[0043] (2) Preparation reaction of CMCS: Take out the CS that has been frozen for 24 hours from the refrigerator, and after the temperature rises to room temperature, weigh 30 g of basified CS and add it to a three-necked flask, then add 200 mL of isopropanol as a dispersion medium, and stir mechanically 30min and adjust the temperature to 55°C. Then weigh 5g of chloroacetic acid and add it into the three-necked flask. After 15min, weigh 10g of chloroacetic acid and add it slowly, set the reaction time to 6h, a...

Embodiment 2

[0055] Preparation of hydrogel:

[0056] The difference between this example and Example 1 is that 0.8mL of OHA solution was added to 2.0mL of CMCS / COP solution, stirred thoroughly and left to form a gel, which was coded as CCHA-4.

Embodiment 3

[0058] Preparation of hydrogel:

[0059] The difference between this example and Example 1 is that 1.2mL of OHA solution was added to 2.0mL of CMCS / COP solution, stirred thoroughly and left to form a gel, coded as CCHA-6.

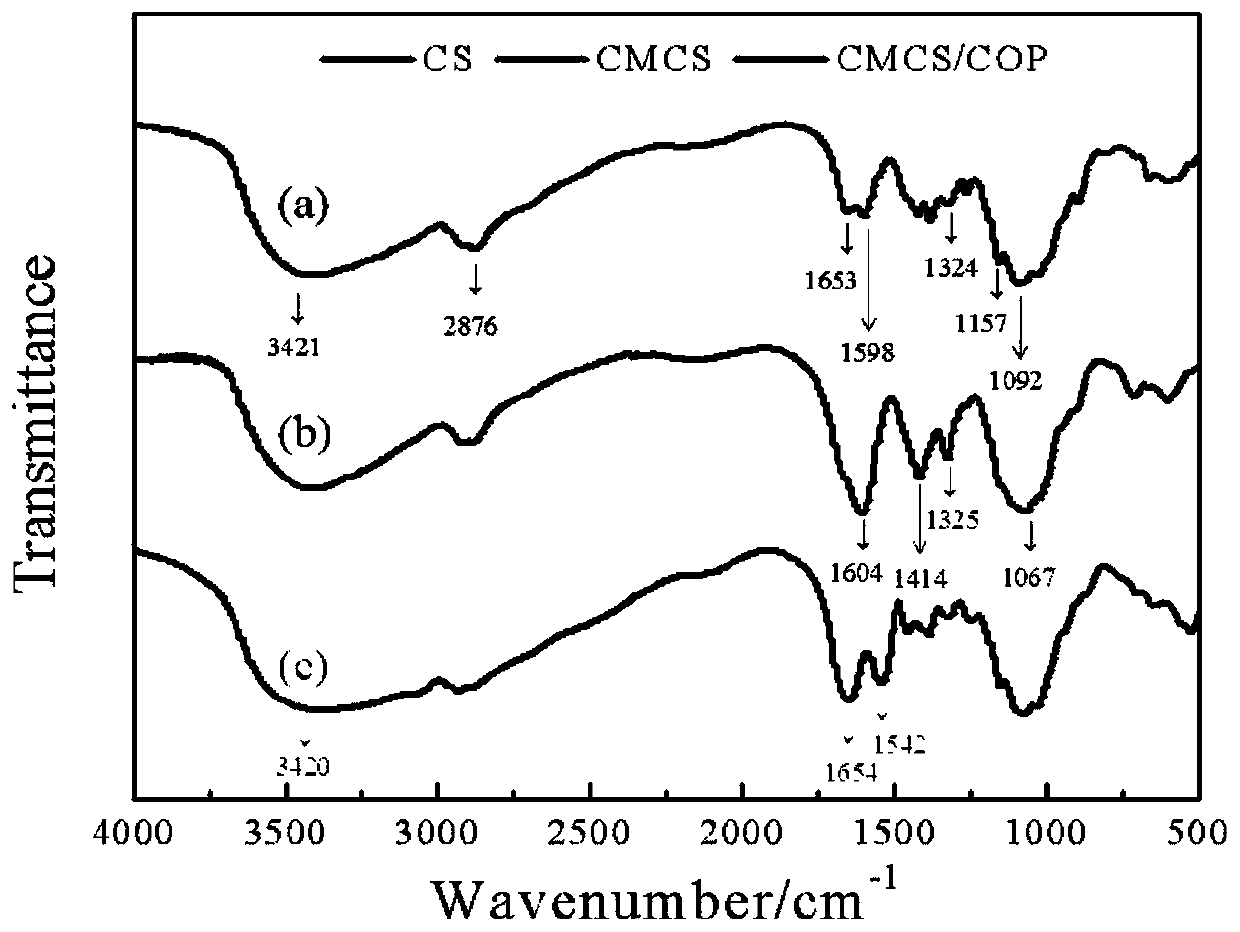

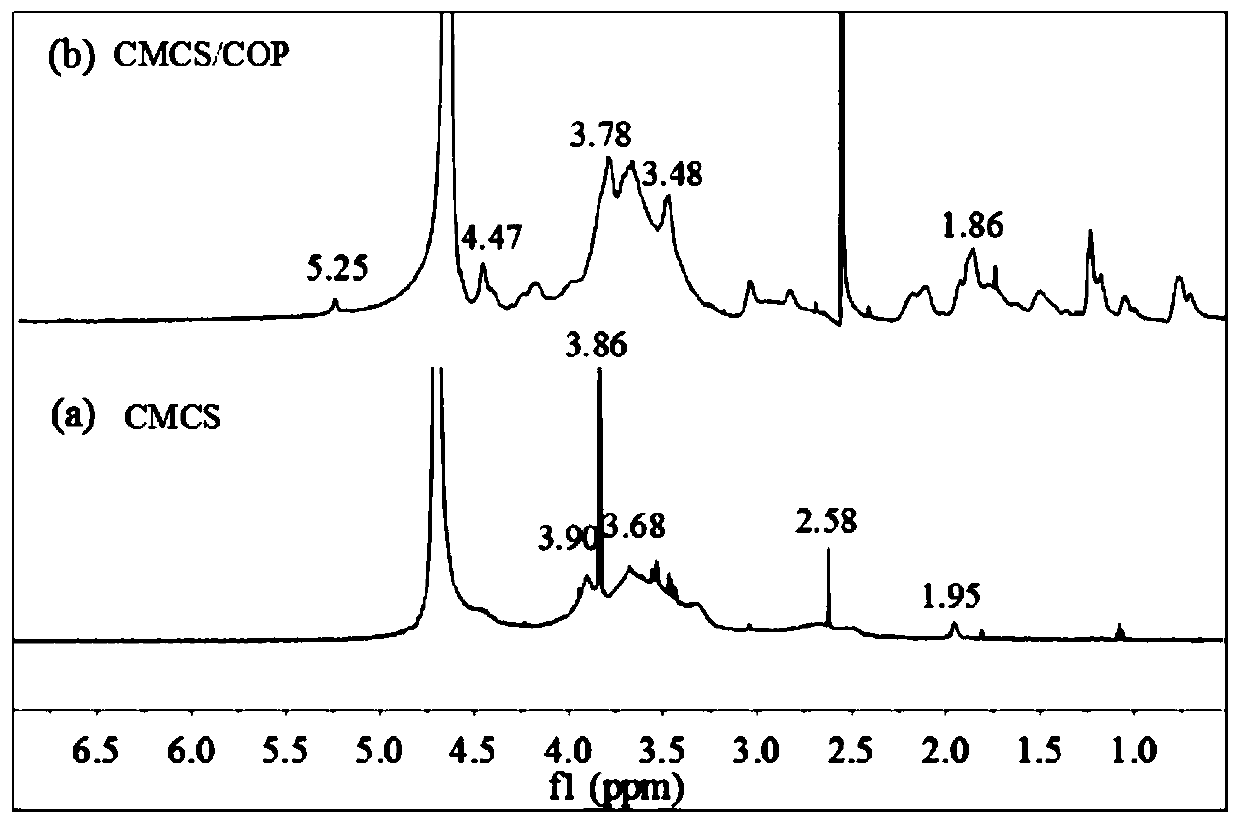

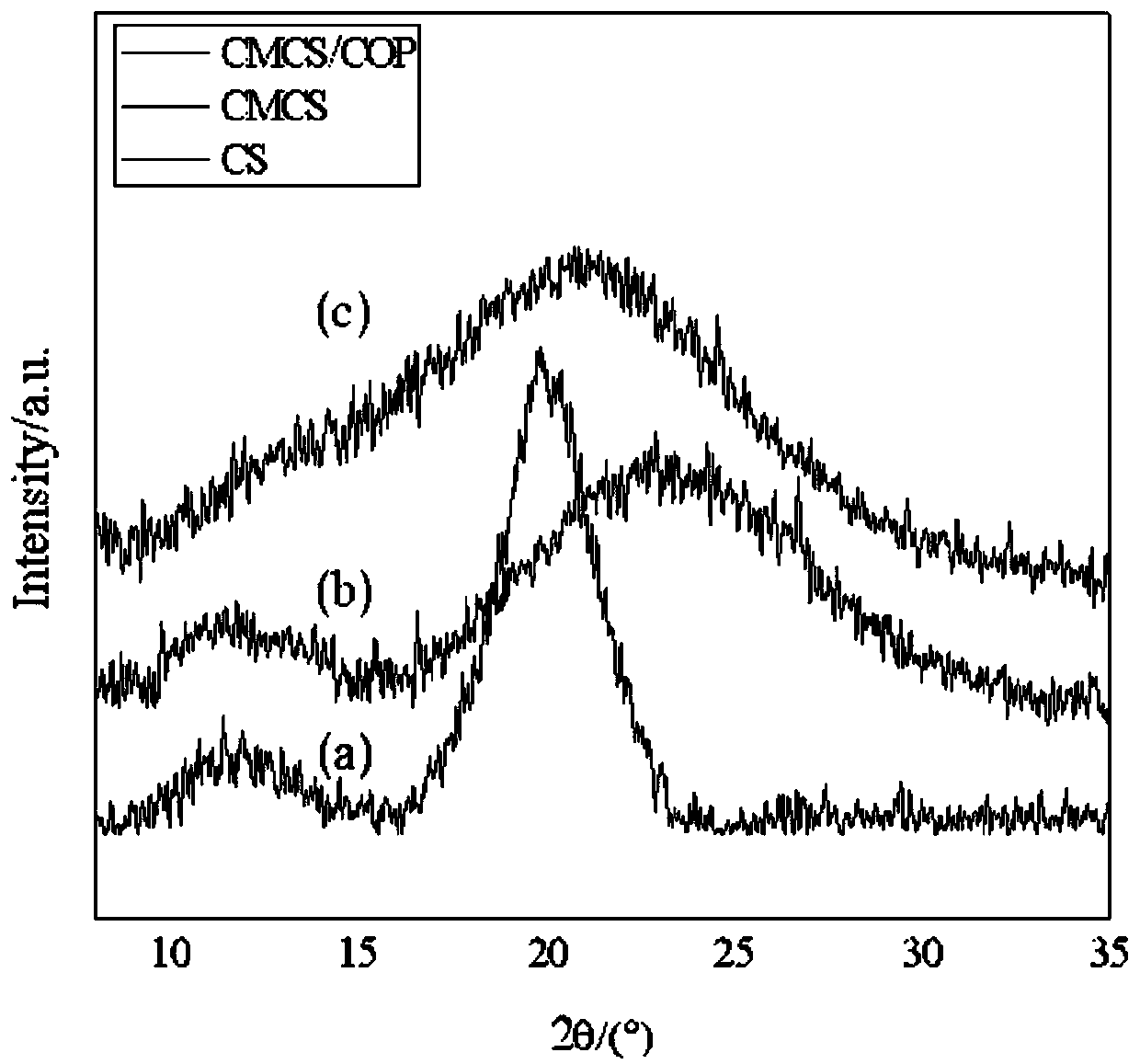

[0060] Carry out infrared characterization to raw material HA in embodiment 1, the prepared OHA and the CCHA-6 hydrogel prepared in embodiment 3, see the attached Figure 5 , the results showed that the amino groups in CMCS / COP and the aldehyde groups in OHA had a cross-linking reaction, and were connected in the form of amide bonds to form a composite hydrogel. The CCHA-6 hydrogel prepared in Example 3 is characterized by a scanning electron microscope, and the scanning electron microscope picture of the hydrogel sample section is shown in the attached Figure 6 , the results show that this hydrogel has a uniformly distributed pore structure, good continuity, smooth and flat pore structure, and a certain thickness. This excellent three-dimensional space ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation state | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com