Bioreactor and method for preparing pectin oligosaccharide and natural food preservative of pectin oligosaccharide

A bioreactor, pectin oligosaccharide technology, applied in specific-purpose bioreactors/fermenters, biochemical equipment and methods, enzyme production/bioreactors, etc., can solve temperature and pH difficult to control, substrates Axial diffusion inhibition, easy loss of immobilized enzymes, etc., to improve reusability, facilitate efficient recovery, and facilitate industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

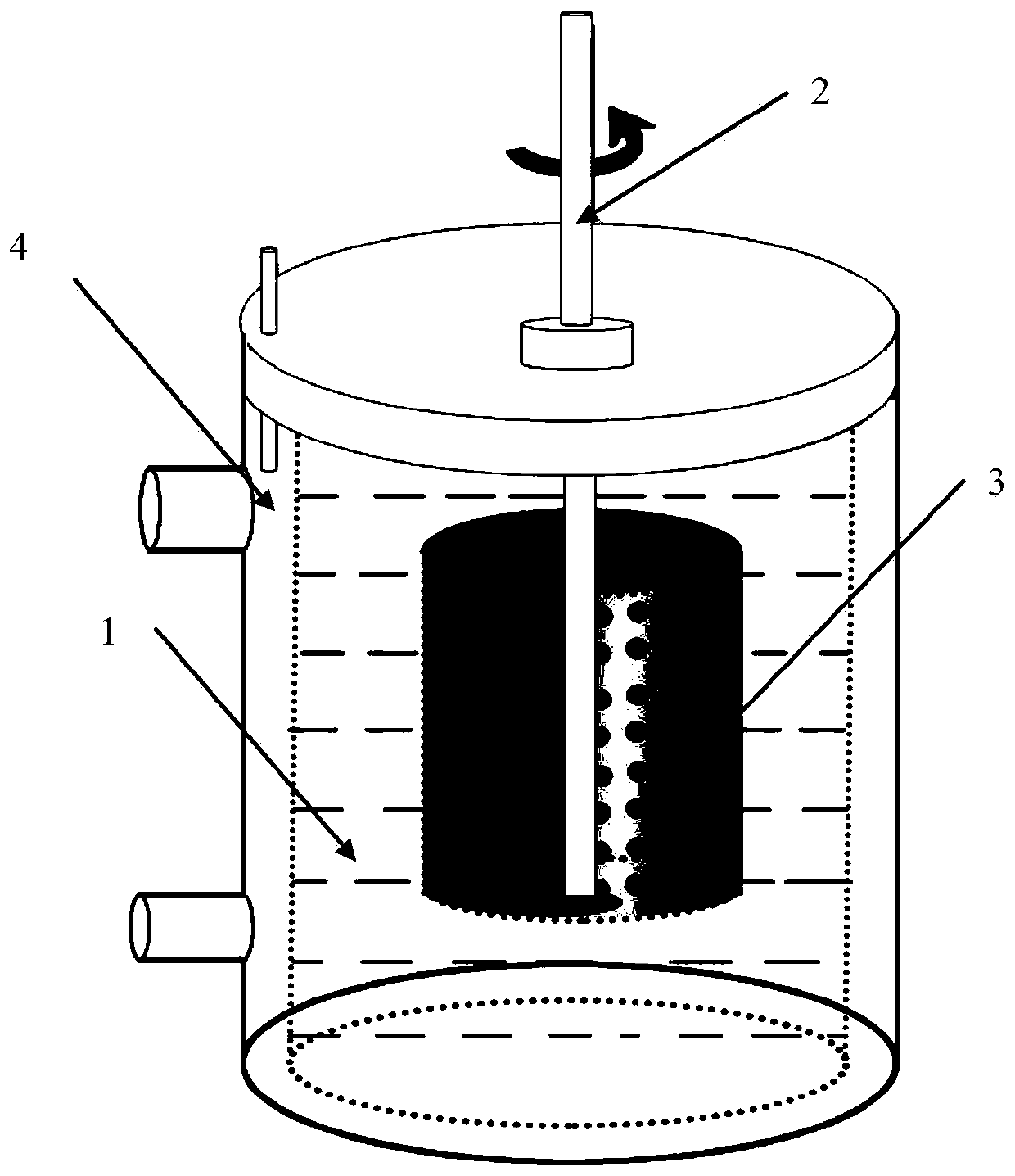

[0066] A kind of bioreactor for preparing pectin oligosaccharides, its structural schematic diagram is shown in figure 1 , including a substrate tank 1, an enzyme carrier 3, a temperature control system 4 and a drive 2;

[0067] A driver 2 is arranged on the top of the substrate tank 1 , an enzyme carrier 3 is arranged at the lower end of the driver 2 , and a temperature control system 4 is arranged on the periphery of the substrate tank 1 .

[0068] The enzyme carrier 3 is filled with graded-pore carbon microsphere carrier immobilized pectinase; and the graded filling is carried out according to the macroscopic particle size of the graded-pore carbon microsphere carrier immobilized pectinase 3cm:5mm=3:7.

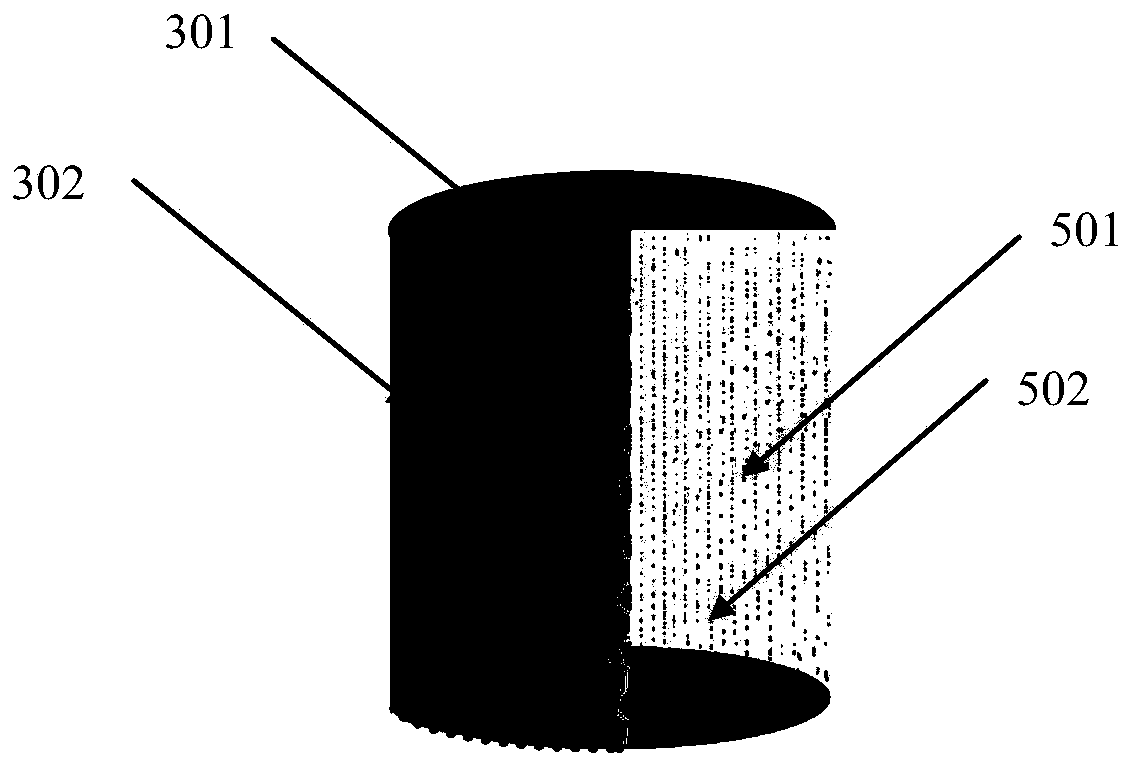

[0069] Wherein, the schematic diagram of the structure of the enzyme carrier is shown in figure 2 , which includes an enzyme carrier housing 301 and a through hole 302 arranged on the enzyme carrier housing, wherein the charcoal microsphere carrier with a macroscopic part...

Embodiment 2

[0084] Production of pectin oligosaccharides with the bioreactor for preparing pectin oligosaccharides in embodiment 1, its specific method is as follows:

[0085] step 1:

[0086] Take an aqueous pectin solution with a mass percentage concentration of 0.1%, adjust the pH to 4, add it to the substrate tank of the bioreactor for preparing pectin oligosaccharides, and immerse the enzyme carrier provided at the lower end of the actuator in the aqueous pectin solution. Adjust the temperature control system so that the temperature of the pectin aqueous solution in the substrate tank is 40°C, and the immobilized pectinase in the fixed pectinase in the carbon microsphere carrier filled in the enzyme carrier is contacted with the pectin for 4 hours to decompose and react to obtain Pectin breakdown products;

[0087] Step 2:

[0088] The decomposed pectin product is treated with a hollow fiber membrane to recover pectin oligosaccharides with a molecular weight of 3000 daltons or less...

Embodiment 3

[0090] Production of pectin oligosaccharides with the bioreactor for preparing pectin oligosaccharides in Example 1, its specific method is as follows: Step 1:

[0091] Take an aqueous pectin solution with a mass percentage concentration of 0.5%, adjust the pH to 4, add it to the substrate tank of the bioreactor for preparing pectin oligosaccharides, and immerse the enzyme carrier provided at the lower end of the actuator in the aqueous pectin solution. Adjust the temperature control system so that the temperature of the pectin aqueous solution in the substrate tank is 45°C, and the immobilized pectinase in the fixed pectinase in the carbon microsphere carrier filled in the enzyme carrier is contacted with the pectin for 8 hours to decompose and react to obtain Pectin breakdown products;

[0092] Step 2:

[0093] The pectin decomposition product is subjected to ultrafiltration and nanofiltration treatment with a size-exclusion filtration membrane, and pectin oligosaccharides wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com