Anodic oxide film pre-hole-sealing method and hole sealing agent

A technology of anodic oxidation film and sealing agent, which is applied in the direction of anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc. It can solve the problems of being unable to pass the acid-base test stably, it is difficult to ensure the stability of alkali resistance, and losing the metal texture. , to achieve super hydrophobicity, excellent adhesion, and improve the effect of hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

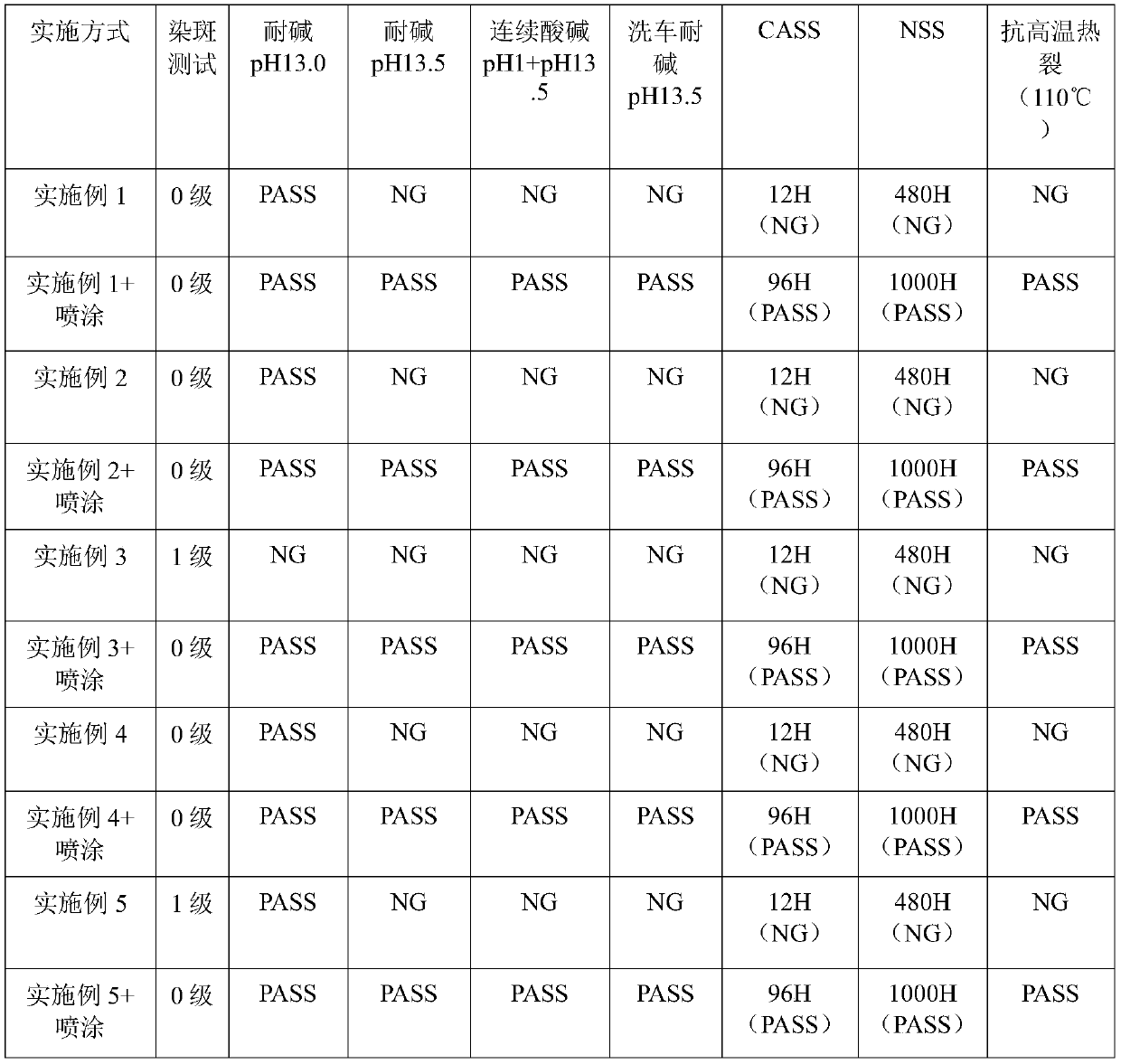

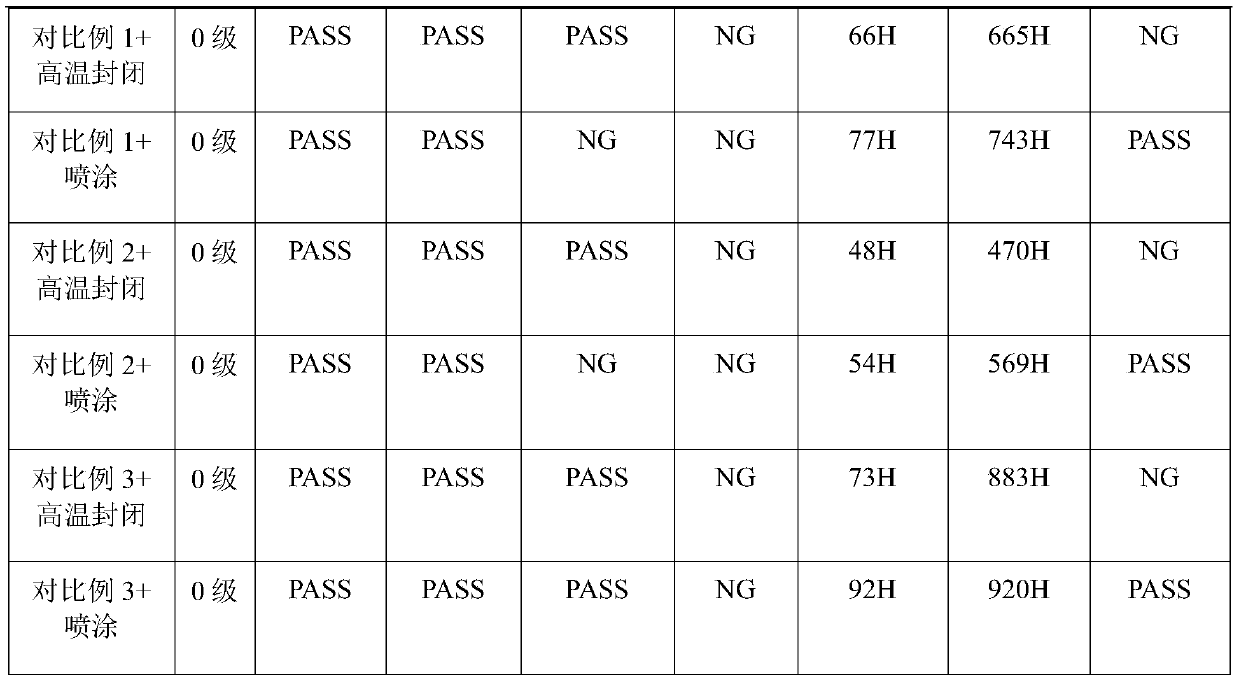

Examples

Embodiment 1

[0065] This embodiment discloses a kind of sealing agent for anodized film pre-sealing, and the sealing agent comprises the following components:

[0066] Nickel acetate: 2g / l,

[0067] Nickel fluoride: 3g / l,

[0068] Polyethylene glycol: 0.1g / l,

[0069] Sodium lignosulfonate: 0.1g / l,

[0070] Acetic acid: 0.05g / l,

[0071] Graphene oxide (single layer): 0.01g / l,

[0072] Sodium lauryl sulfate: 0.05g / l,

[0073] The solvent is pure water.

Embodiment 2

[0075] This embodiment discloses a pre-sealing agent for anodized film, which includes the following components:

[0076] Nickel acetate: 5g / l,

[0077] Ammonium fluoride: 0.5g / l,

[0078] Sorbitol: 0.1g / l,

[0079] Sodium methylene bis-naphthalene sulfonate: 0.15g / l,

[0080] Acetic acid: 0.01g / l,

[0081] Graphene oxide (single layer): 0.03g / l,

[0082] Alkylphenol polyoxyethylene ether: 0.1g / l,

[0083] The solvent is pure water.

Embodiment 3

[0085] This embodiment discloses a pre-sealing agent for anodic oxide film, including the following components:

[0086] Nickel fluoride: 4g / l,

[0087] Sodium fluoride: 0.5g / l,

[0088] Polyethylene glycol: 0.3g / l,

[0089] Sodium methylene bis-naphthalene sulfonate: 0.2g / l,

[0090] Acetic acid: 0.02g / l,

[0091] Graphene oxide (single layer): 0.1g / l,

[0092] Fatty alcohol polyoxyethylene ether: 0.5g / l,

[0093] The solvent is pure water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com