Sodium ion gradient doped spinel structure positive electrode active material and preparation method thereof

A positive electrode active material and spinel structure technology, applied in the direction of structural parts, battery electrodes, electrical components, etc., can solve problems such as harsh conditions, unfavorable large-scale industrial production, complex synthesis process, etc., achieve good performance and improve electrochemical performance. The effect of simple performance and process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 2g of sodium alginate was dissolved in 50g of deionized water to form a solution, and 100g of LiNi 0.5 mn 1.5 o 4 (purchased from Shandong Qixing Energy Materials Co., Ltd.) was uniformly mixed with the above solution to form a slurry, and the above slurry was spray-dried at 140°C to form a dry powder, and the above dry powder was placed in a box furnace and calcined at 600°C for 5 hours , the heating rate is 3°C / min, the cooling rate is 1°C / min, and finally the sodium ion gradient doped LiNi 0.5 mn 1.5 o 4 Positive active material.

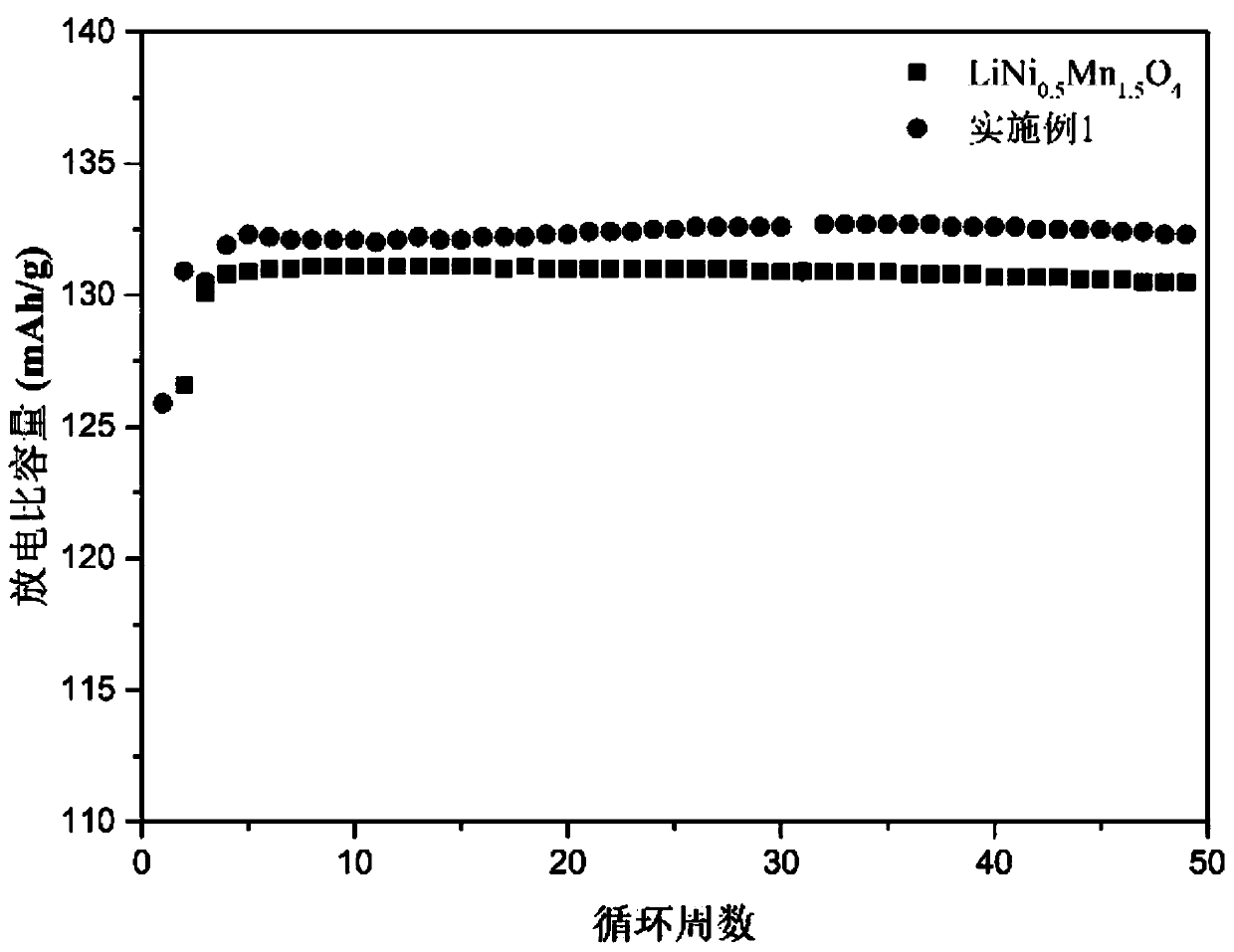

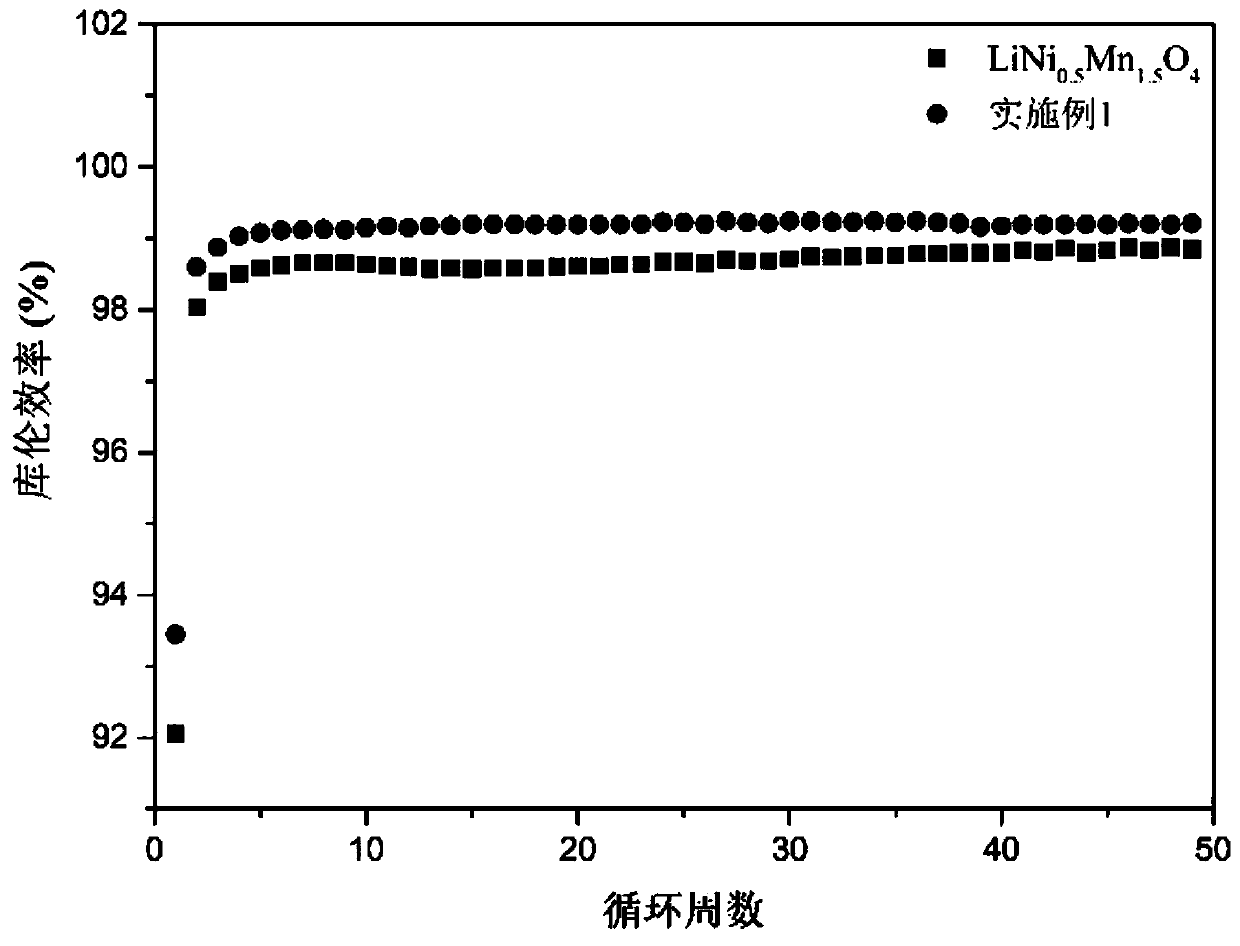

[0033] see figure 1 and figure 2It can be known that the sodium ion gradient doped LiNi prepared in Example 1 0.5 mn 1.5 o 4 Compared with the original material, the cycle and efficiency of the positive electrode active material at high temperature are significantly improved.

Embodiment 2

[0035] 1.5g of sodium hydroxymethylcellulose was dissolved in 50g of deionized water to form a solution, and 100g of LiNi 0.5 mn 1.5 o 4 (purchased from Shandong Qixing Energy Materials Co., Ltd.) was uniformly mixed with the above solution to form a slurry, and the above slurry was stirred and evaporated in an oil bath at 120° C. to form a dry powder, and the above dry powder was placed in a box furnace in Calcined at 700°C for 5 hours, with a heating rate of 3°C / min and a cooling rate of 1°C / min, finally obtaining sodium ion gradient doped LiNi 0.5 mn 1.5 o 4 Positive active material.

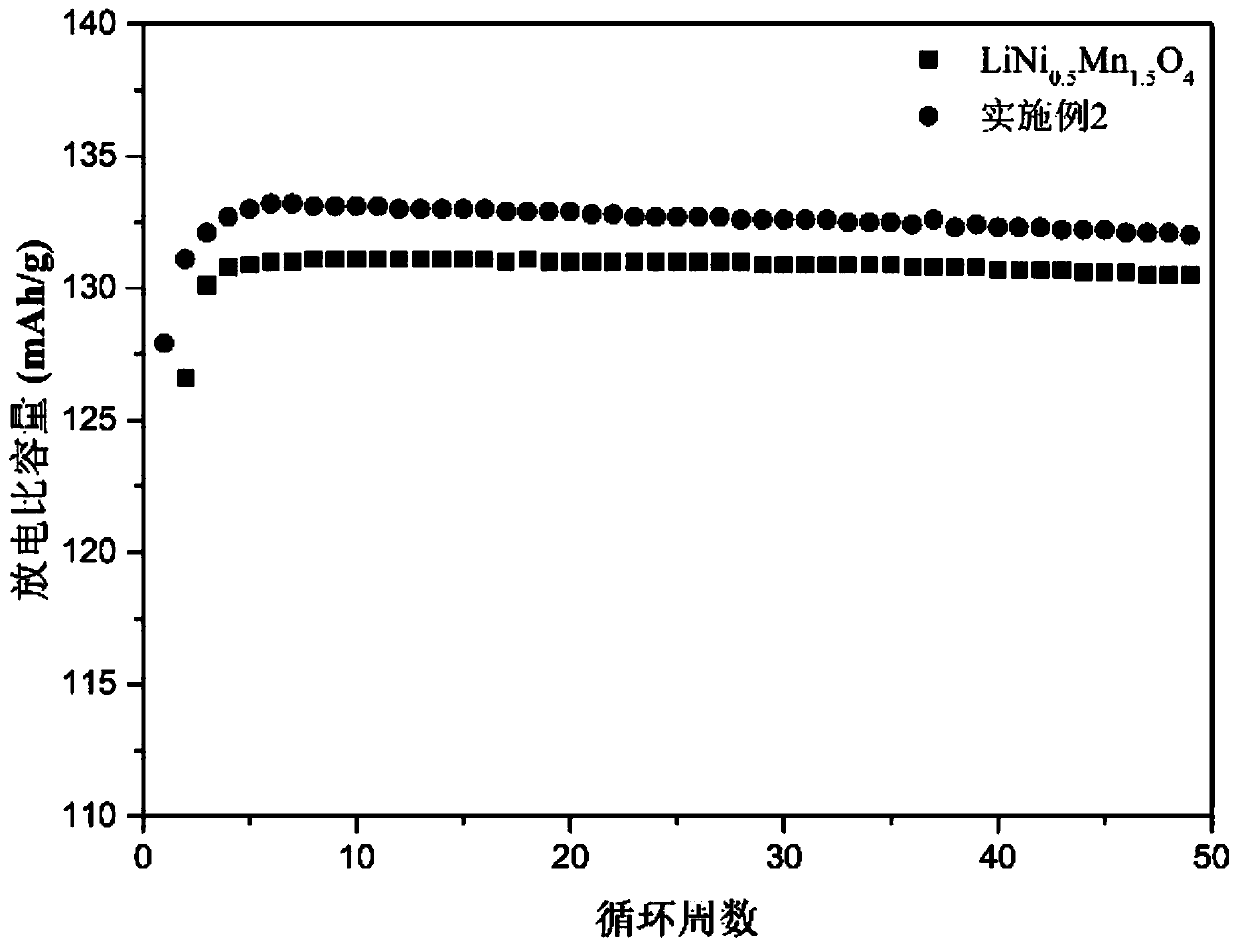

[0036] see image 3 and Figure 4 It can be known that the sodium ion gradient doped LiNi prepared in Example 2 0.5 mn 1.5 o 4 Compared with the original material, the cycle and efficiency of the positive electrode active material at high temperature are significantly improved. From Figure 7 It can be seen that the gradient sodium ion doped LiNi prepared in Example 2 0.5 mn 1.5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com