Disintegration type efficient granular magnesium sulfate fertilizer and preparation method thereof

A technology of magnesium sulfate and magnesium sulfate powder, which is used in magnesium fertilizers, inorganic fertilizers, fertilization devices, etc., can solve the problem that it still takes a long time for complete dissolution, the disintegration time of granular magnesium sulfate is slow, and there is no disintegrating magnesium sulfate particles. Patent information and other issues, to achieve the effect of improving nutrient utilization efficiency, promoting crop rooting and germination, and high disintegration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

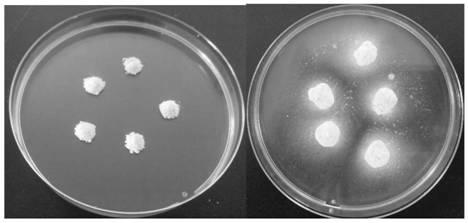

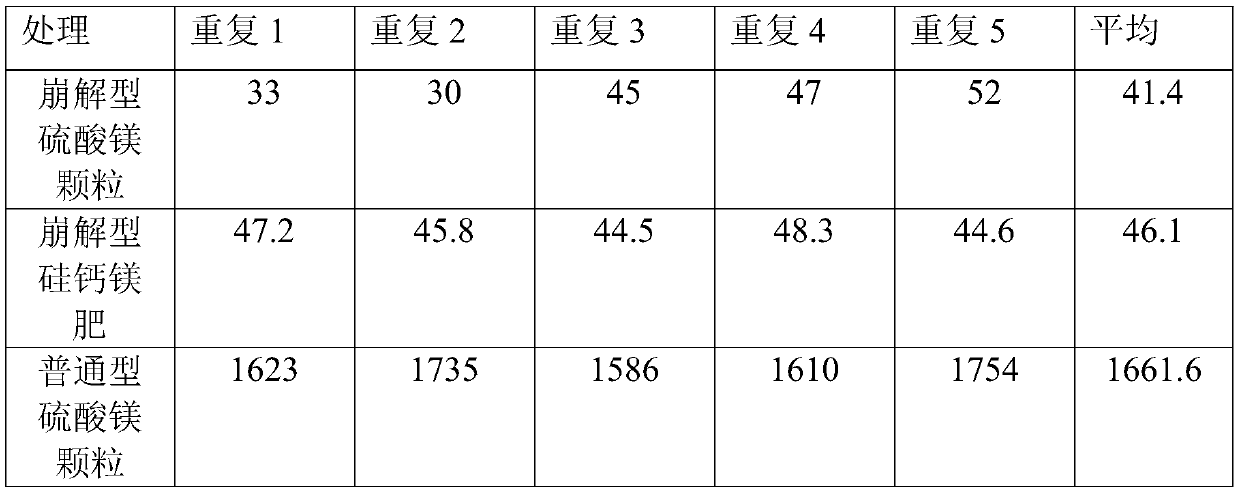

Image

Examples

Embodiment 1

[0048] Embodiment 1, preparation disintegration type granular magnesium sulfate fertilizer composition

[0049] (1) Weigh 90g of magnesium sulfate powder, 4.75g of citric acid, 4.75g of sodium bicarbonate, and 0.5g of potassium fulvic acid, and completely mix the different materials evenly.

[0050] (2) Pour the fully mixed material into the granulator, adjust the speed of the granulator to 28r / min,

[0051] (3) Use deionized water as a binder, and spray it evenly on the material to make it into a ball and granulate.

[0052] (4) Put the obtained granular fertilizer in a blast drying oven, and dry it at 30° C. for 1-2 hours.

[0053] (5) Take out, cool to room temperature, sieve the fertilizer granules with 2-4mm diameter with test sieve, obtain the disintegrating granular magnesium sulfate granule provided by the present invention.

Embodiment 2

[0054] Embodiment 2, preparation disintegration type granular magnesium sulfate fertilizer composition

[0055] (1) Weigh 85g of magnesium sulfate powder, 7g of citric acid, 7g of sodium bicarbonate, and 1g of potassium fulvic acid respectively, and completely mix the different materials evenly.

[0056] (2) Pour the fully mixed material into the granulator, adjust the speed of the granulator to 28r / min,

[0057] (3) Use deionized water as a binder, and spray it evenly on the material to make it into a ball and granulate.

[0058] (4) Put the obtained granular fertilizer in a blast drying oven, and dry it at 30° C. for 1-2 hours.

[0059] (5) Take it out, cool to room temperature, and get 2-4mm diameter fertilizer granules with a test sieve to obtain the disintegrating granular magnesium sulfate fertilizer granules provided by the invention.

Embodiment 3

[0060] Embodiment 3, preparation disintegration type granular magnesium sulfate fertilizer composition

[0061] (1) Weigh 89g of magnesium sulfate powder, 4.5g of citric acid, and 5g of sodium bicarbonate respectively, and completely mix the different materials evenly.

[0062] (2) Pour the fully mixed material into the granulator, and adjust the speed of the granulator to 28r / min.

[0063] (3) Use the citric acid of 0.5wt% potassium fulvic acid aqueous solution and 0.5wt% citric acid as binding agent, alternately and evenly spray on the material to make it into ball granulation.

[0064] (4) Put the obtained granular fertilizer in a blast drying oven, and dry it at 30° C. for 1-2 hours.

[0065] (5) Take it out, cool to room temperature, and get 2-4mm diameter fertilizer granules with a test sieve to obtain the disintegrating granular magnesium sulfate fertilizer granules provided by the invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com