Solvent-resistant cross-linked polyimide film with high dimensional stability

A polyimide film, dimensional stability technology, applied in the field of cross-linked polyimide film, can solve the problem that the dimensional stability and mechanical properties of the film cannot be more effectively improved, the service life is reduced, the overall performance is reduced, etc. problems, to achieve colorless and transparent heat resistance and mechanical properties, improve light transparency, excellent heat resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

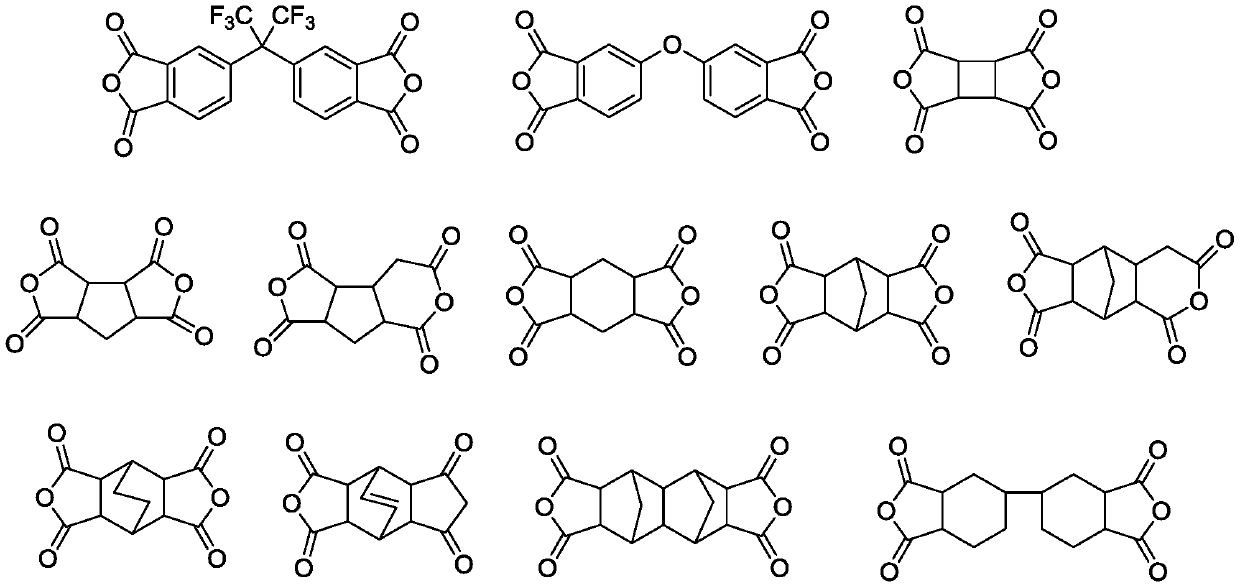

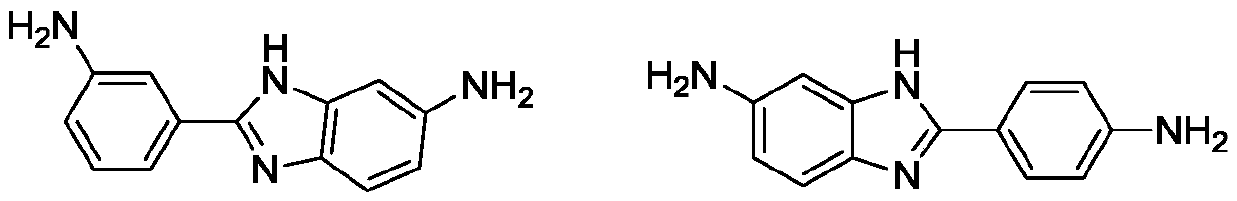

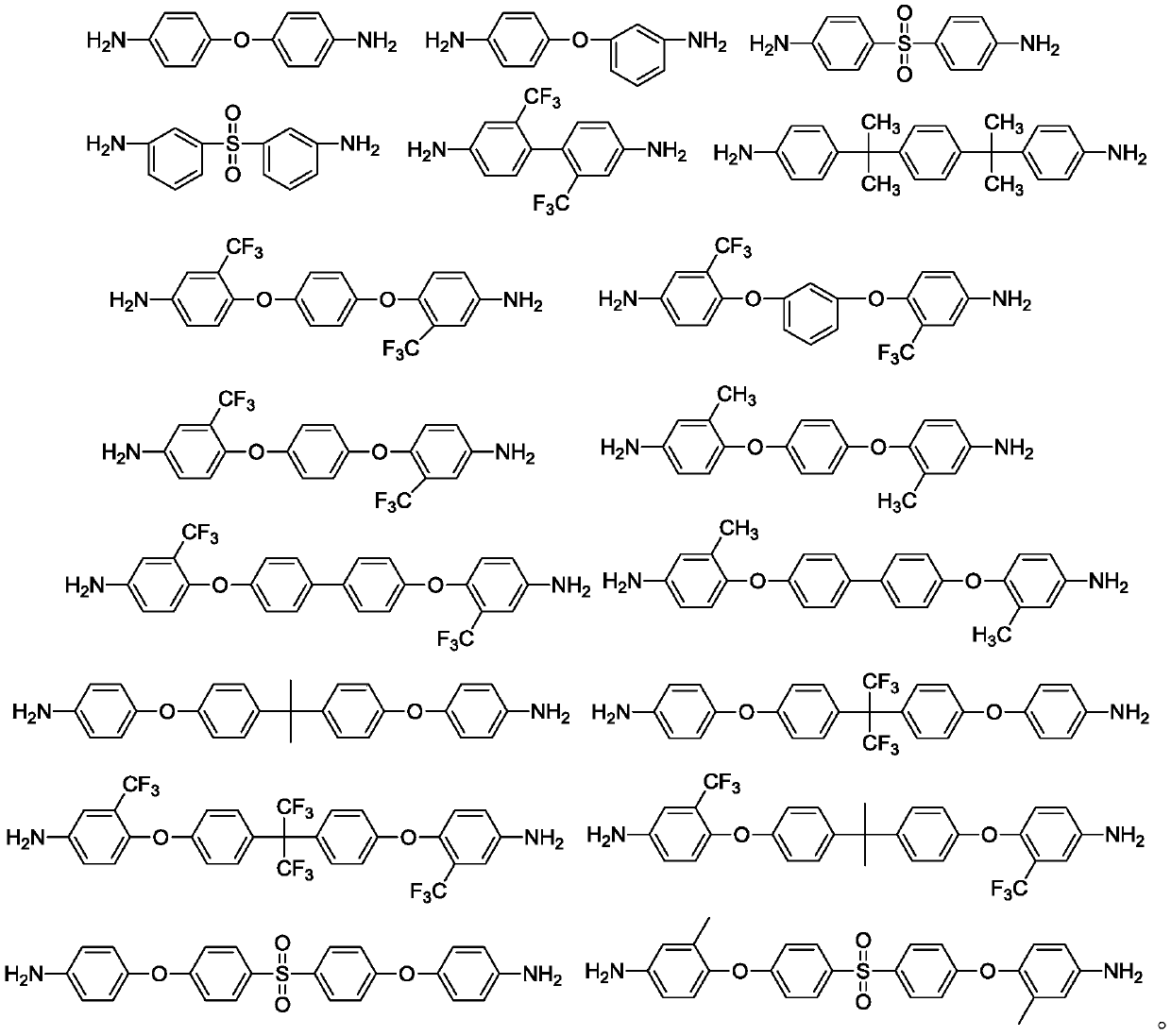

Method used

Image

Examples

Embodiment 1

[0043] A solvent-resistant and high-dimensionally stable cross-linked polyimide film, the preparation method of which comprises:

[0044] S1. Under a nitrogen atmosphere, dissolve 8mmol 4,4'-diaminodiphenyl ether and 2mmol 2-(3-aminophenyl)-5-aminobenzimidazole as diamine monomer raw materials in 28ml of N,N -In the solvent of dimethylacetamide, after stirring until completely dissolved, add 10mmol 4,4'-(hexafluoroisopropene) diphthalic anhydride as the tetracarboxylic dianhydride monomer raw material, then continue stirring until completely dissolved to obtain a solid A homogeneous solution with a content of 20wt% was reacted at 5°C for 8 hours to obtain a polyamic acid solution, and 0.98ml of pyridine was added to the polyamic acid solution as an imidization agent, and 9.5ml of acetic anhydride was added after the dispersion was complete As a dehydrating agent, after stirring again for 4 hours, move the reaction solution to the dropping funnel, drop it at a rate of 2-3 drops...

Embodiment 2

[0047] A solvent-resistant and high dimensional stability cross-linked polyimide film, the preparation method of this polyimide film is the same as in Example 1, except that in step S1, 8mmol 2,2'-bis( Trifluoromethyl)-4,4'-diaminobiphenyl and 2mmol 2-(3-aminophenyl)-5-aminobenzimidazole are used as diamine monomer raw materials, and the polyimide film thus obtained The relevant performance test results are shown in Table 1.

Embodiment 3

[0049] A solvent-resistant and high dimensional stability cross-linked polyimide film, the preparation method of this polyimide film is the same as in Example 1, except that in step S1, 8mmol 4,4'-bis( 2-trifluoromethyl-4-aminophenoxy)benzene and 2mmol 2-(3-aminophenyl)-5-aminobenzimidazole are used as diamine monomer raw materials, and the polyimide film thus obtained The relevant performance test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com