Self-cleaning water-based finish-coat paint and preparation method thereof

A self-cleaning, finish paint technology, applied in the field of coatings, can solve the problems of stains, easy to be stained, and loss of decorative effect of the coating, and achieve the effects of reducing odor, excellent color retention, and long-lasting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

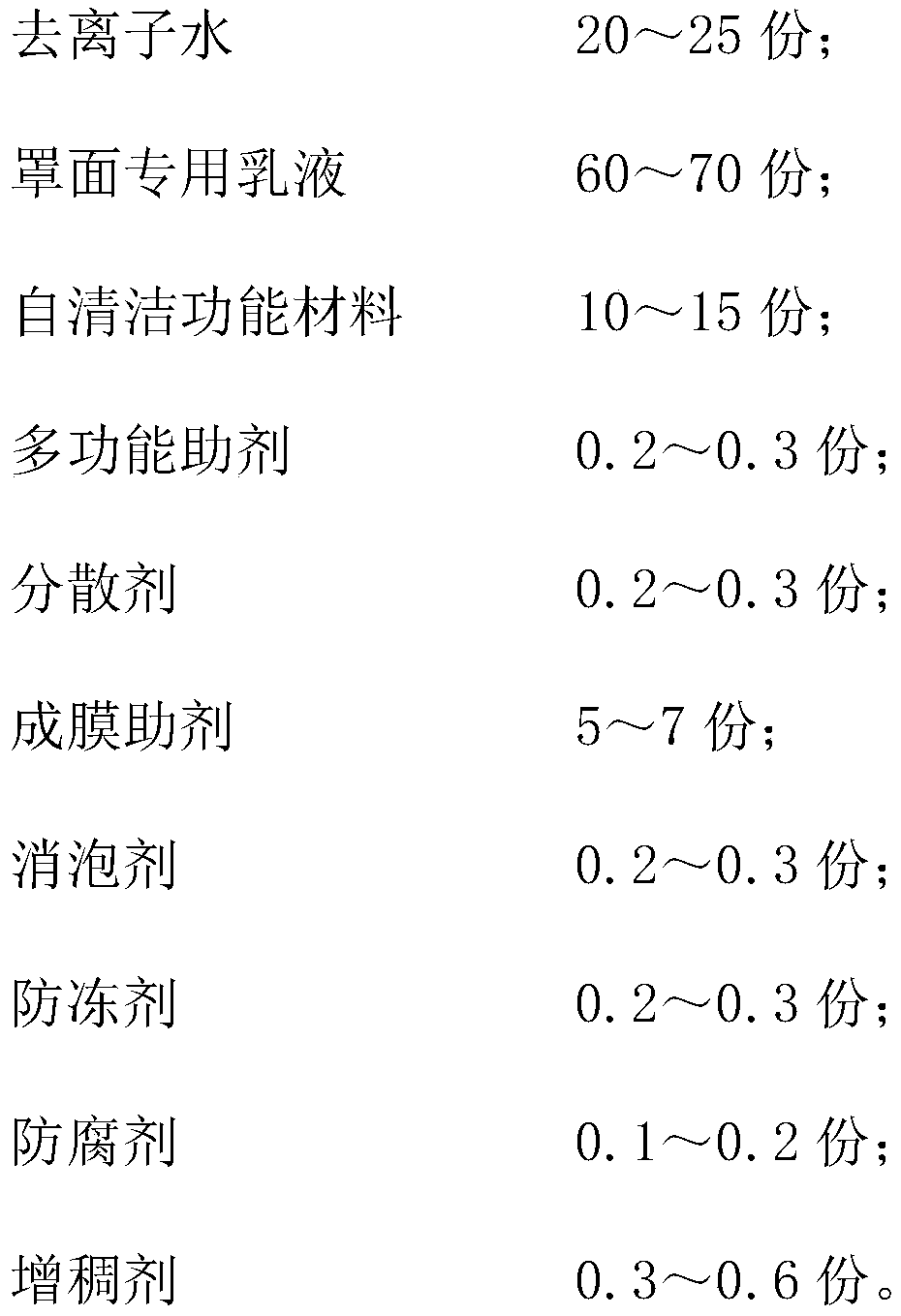

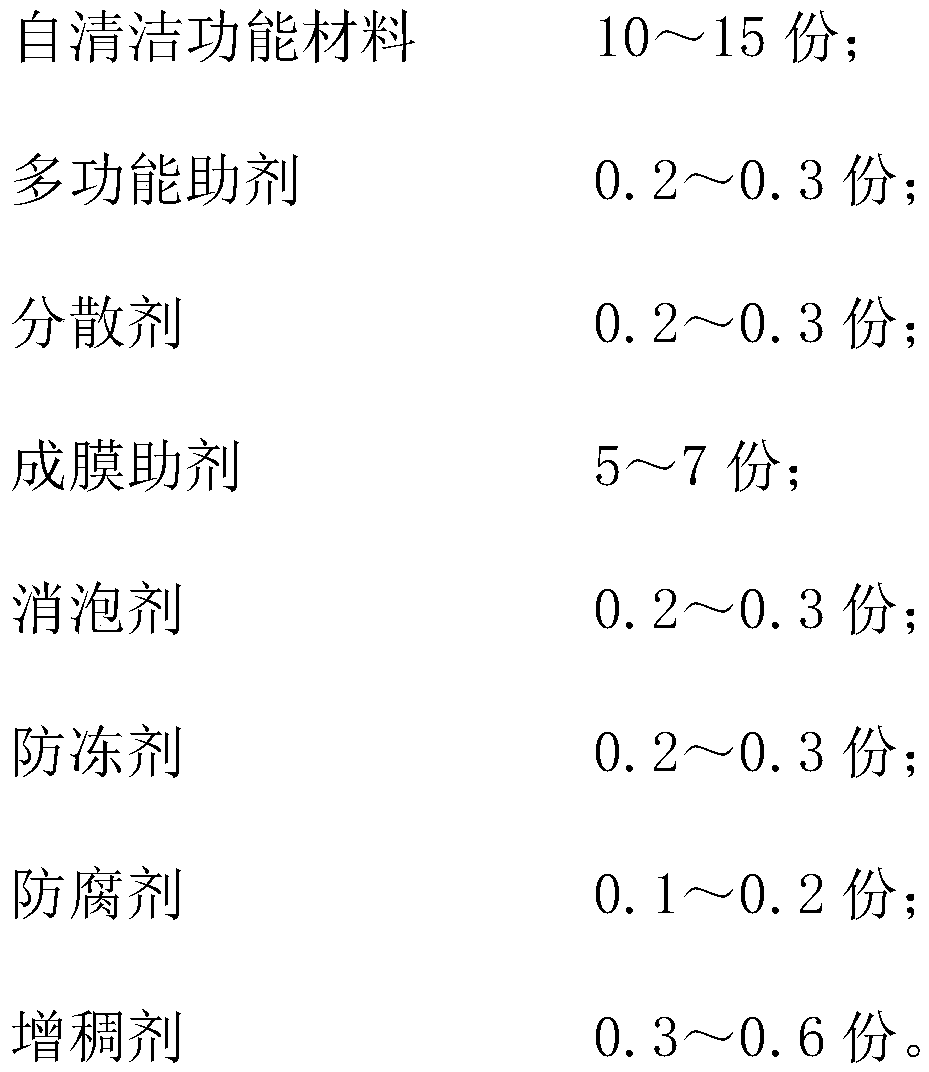

[0051] A kind of self-cleaning water-based finish paint, by mass percentage, comprises the following components:

[0052]

[0053]

[0054] Preparation:

[0055] (1) Add deionized water, special emulsion for covering, self-cleaning functional materials into the reaction kettle and mix well;

[0056] (2) Mix the film-forming auxiliary agent and the multifunctional auxiliary agent uniformly in advance and add them to the reaction kettle, and disperse for 10 minutes at a rotating speed of 500r / min;

[0057] (3) Add defoamer, antifreeze, preservative in described reaction kettle, disperse 15min under 600r / min rotating speed, then add thickener, stir 10min with 800r / min rotating speed, to viscosity 65s, namely obtained from Clean water-based finishes.

Embodiment 2

[0059] A self-cleaning water-based finish paint, in parts by mass, comprises the following components:

[0060]

[0061]

[0062] Preparation:

[0063] (1) Add deionized water, special emulsion for covering, self-cleaning functional materials into the reaction kettle and mix well;

[0064] (2) Mix the film-forming auxiliary agent and the multifunctional auxiliary agent uniformly in advance and add them to the reaction kettle, and disperse for 15 minutes at a rotating speed of 550r / min;

[0065] (3) Add defoamer, antifreeze, preservative to described reactor, disperse 18min under 700r / min rotating speed, then add thickener, stir 15min with 900r / min rotating speed, to viscosity 70s, promptly obtains from Clean water-based finishes.

Embodiment 3

[0067] A self-cleaning water-based finish paint, in parts by mass, comprises the following components:

[0068]

[0069]

[0070] Preparation:

[0071] (1) Add deionized water, special emulsion for covering, self-cleaning functional materials into the reaction kettle and mix well;

[0072] (2) Mix the film-forming auxiliary agent and the multifunctional auxiliary agent uniformly in advance and add them to the reaction kettle, and disperse for 20 minutes at a speed of 600r / min;

[0073] (3) Add defoamer, antifreeze, preservative to described reactor, disperse 20min under 800r / min rotating speed, then add thickening agent, stir 20min with 1000r / min rotating speed, to viscosity 75s, obtain from Clean water-based finishes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com